FEC FUSIONE-HS-2 User Manual

Page 50

Chapter 4: System Setup and Wiring

Page 4-12

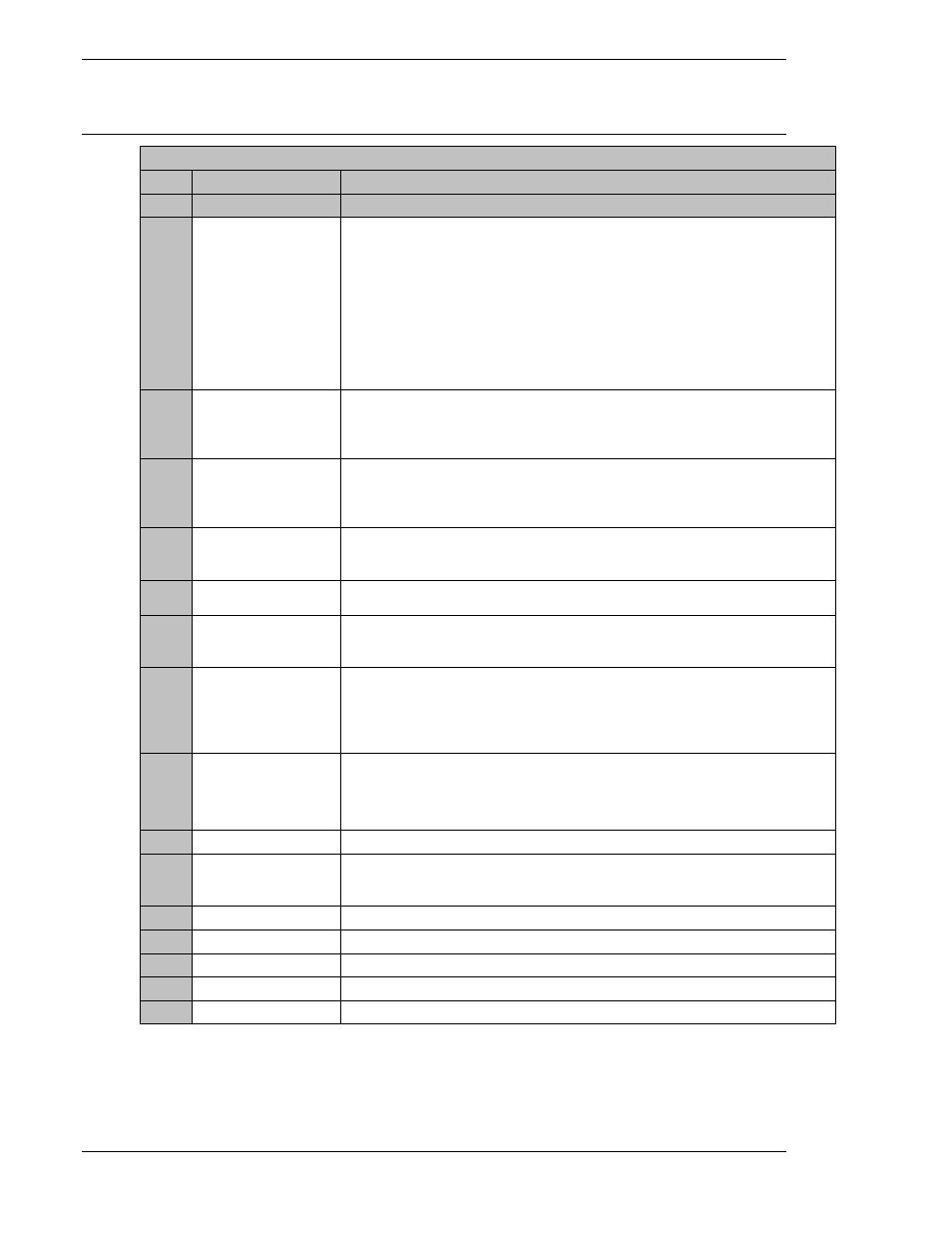

4.7.1 Explanation of CONTROLLER Unit I/O

INPUT SIGNALS

Pin #

SIGNAL NAME

DESCRIPTION

A1 RESET

Reset Input (Normally Open)

When active (on), this signal will clear all fastening data, discrete

outputs, and communication buffers. A Zero Check of the torque

transducer will be completed. During the Zero Check, the Tool

ACCEPT and REJECT lamp will light to indicate the performance of

the Zero Check. If the System has been disabled by an Abnormal

output, the System will not return to normal operation until the

Abnormal condition has been corrected, and this signal has been input

for 200~500 milliseconds. Do not input this signal between cycles, due

to the potential for data loss.

B1 STOP

Emergency Stop Input (Normally Open)

This signal must be inactive (off) for controller operation. When this

signal is active (on), controller operation will stop, and input/outputs

will be disabled.

A2 START

Start Cycle Input (Normally Open)

The Start input automatically resets the previous cycle, clears all data

to zero, and initiates the next fastening cycle. The Start input must be

maintained "on" for the entire cycle.

B2 REVERSE

Reverse Spindle Rotation Input (Normally Open)

The spindle will rotate in an opposite direction for as long as this signal

is activated (on) and maintained. (input disabled during RESET)

A3 SELF CHECK

DISABLE

Input signal used to disable the performance of the automatic Self

Check function at the beginning of the fastening cycle.

B3 BYPASS

Spindle Bypass Input (Normal Open)

When active, all functions of this spindle are bypassed, and the

Bypass output is active. Programming of the Controller is enabled

A4

B4

BANK SELECT 0

BANK SELECT 1

Bank Select Input Signals (Normally Open)

These two (2) inputs form a binary code that is used to define the

function/definition of outputs for Bank Data 0~7 (A11-B14). This

allows up to 32 different output definitions with only 8 discrete outputs

(4 Banks, 8 available outputs per Bank). See 4.7.3 Bank Select Table.

A5

B5

A6

B6

WORK SELECT 1

WORK SELECT 0

WORK SELECT 3

WORK SELECT 2

Work / Parameter Select Input (Normally Open)

These 4 inputs form a binary code which is capable of selecting up to

16 different sets of Fastening Parameters. Refer to Section 4.7.2

Work Sequence Select Table.

A7 NOT USED

B7 WORK OK RESET

Reset Batch count to the initial condition/Count. D-NO display will be

cleared. (If controller is setup for the work select from TB1, this input

MUST be used to reset the batch count)

A8 NOT USED

A9 INPUT COMMON

Input signal common. Connection to +12 ~ 24 VDC required.

B9 OUTPUT COMMON Output signal common. Connection to 0 VDC required

A10 DC POWER (+24v) Auxiliary 24VDC power – 0.5amp max.

B10 DC POWER (0v)

Zero volt common for Auxiliary power