FEC FUSIONE-HS-2 User Manual

Page 40

Chapter 4: System Setup and Wiring

Page 4-2

4.1

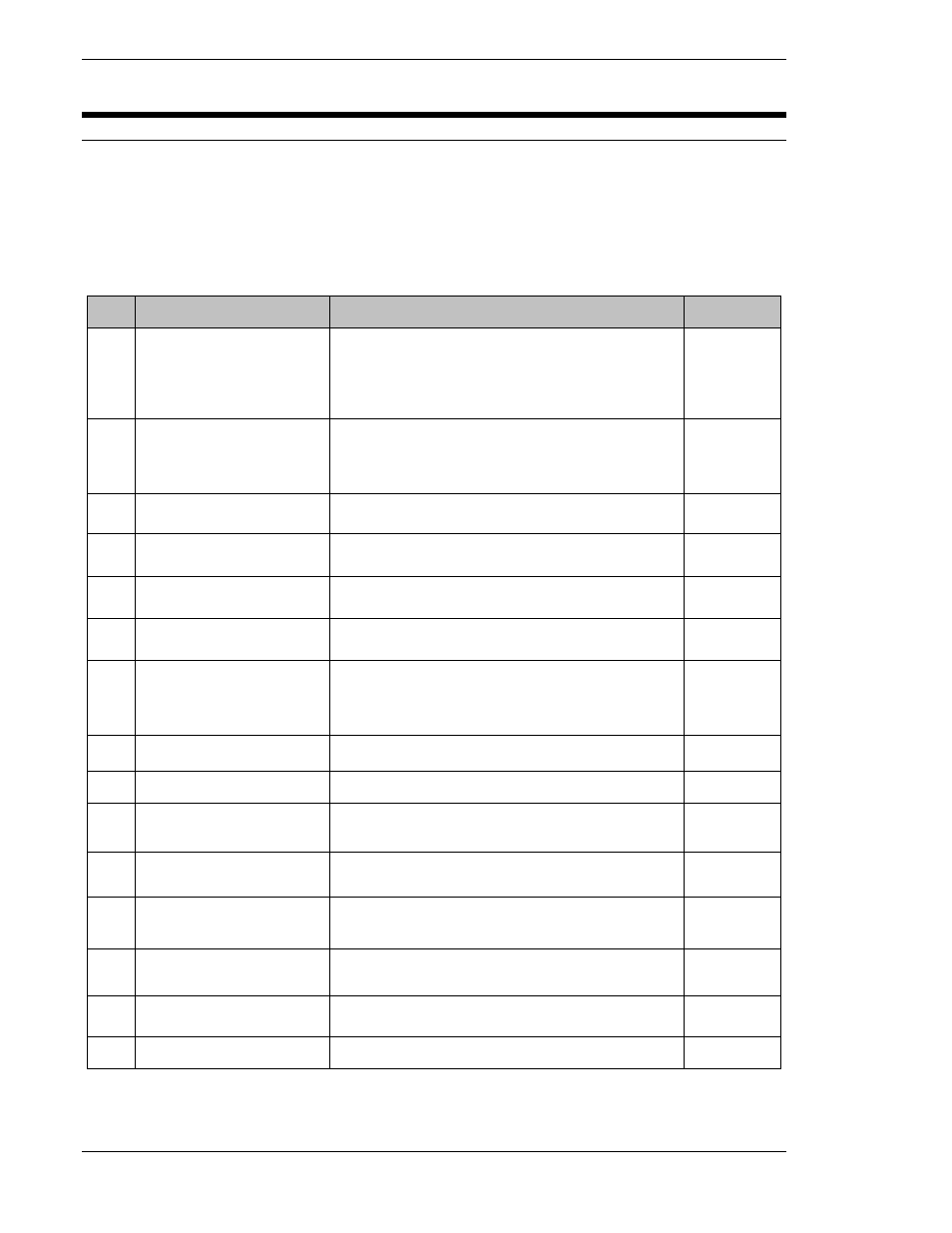

Design and Build Procedure

Review Chapters 1 and 2 prior to designing a System.

If the requirements and specifica-

tions in these two (2) Chapters are not addressed, there is a chance of degraded System per-

formance.

WARNING:

Follow Lockout/Tagout and other safety precautions when connecting and/or

disconnecting cabling, wiring, and equipment.

No.

Items

Comments

Reference

Section

1 Select correct tool size.

Keep torque range between 50% and 75 % of tool

capability for best performance and to

compensate for fastening specification revisions.

Verify fastener location and tool clearance

concerns.

2.4.1

4.4.1

4.4.2

2 Determine tool suspension

/reaction requirements.

Determination of suspension and reaction

requirements is dependent upon end user

standard ergonomic design guidelines and

preferred supplier lists.

4.4

4.4.3

3 Select correct Control Unit

for the tool selected.

Different tool motors may require different Servo

Amplifiers. Ensure the correct one is selected.

2.4.1

4 Select the circuit

protectors.

Circuit protection for Controller Units should be

separate from other units.

4.5

4.6

5 Select an adequate PLC. Select a PLC which will facilitate direct connection

to the FUSION System I/O (24 VDC true low).

4.7

6 Design (or review) PLC

logic.

A PLC logic program can be written using signal

descriptions and timing charts provided.

4.7

7 Determine Controller

mounting requirements.

Keep clearances among units according to the

recommended installation layout. End user

specific input should be used to determine

mounting requirements.

4.2

4.3

8 Set Controller Unit dip

switches.

Check the setting before connecting the Unit.

4.10

9 Mount the Controller Units. Refer to recommended installation layout.

4.2

4.3

10 Wire power connections. Connect the power cables.

VERIFY VOLTAGE

PRIOR TO APPLYING POWER.

4.6

11 Wire I/O connections.

Connect all I/O wiring.

VERIFY VOLTAGE

SOURCE PRIOR TO CONNECTION.

4.7

12

Connect Tool / extension

cables.

VERIFY POWER IS OFF

, then connect cables for

every motor, encoder and preamplifier.

Appendix A

13 Turn on the equipment.

VERIFY WIRING AND THE VOLTAGE OF ALL

POWER SUPPLIES PRIOR TO POWERING UP.

5.1

14 Input preset data.

Set the preset data for torque, angle, speed, time,

etc.

Chapter 6

Chapter 7

15 Verify normal function.

Confirm normal operation.

5.2