FEC FUSIONE-HS-2 User Manual

Page 67

FEC FUSION Operations Manual

4.11 Tool Cable Connection

•

Tools are connected to the

ducer preamp, motor and

fication number and should be connected to the corresponding

•

Cables should be supported to reduce fatigue points

allow the cable to move, but yet hold it in place. Cable tie

point leading to premature cable failure.

WARNING:

Do not make motor connections with the power on. Turn off all controller power

before attempting to connect or disconnect any motor cables

Recommended cable length:

Maximum cable length:

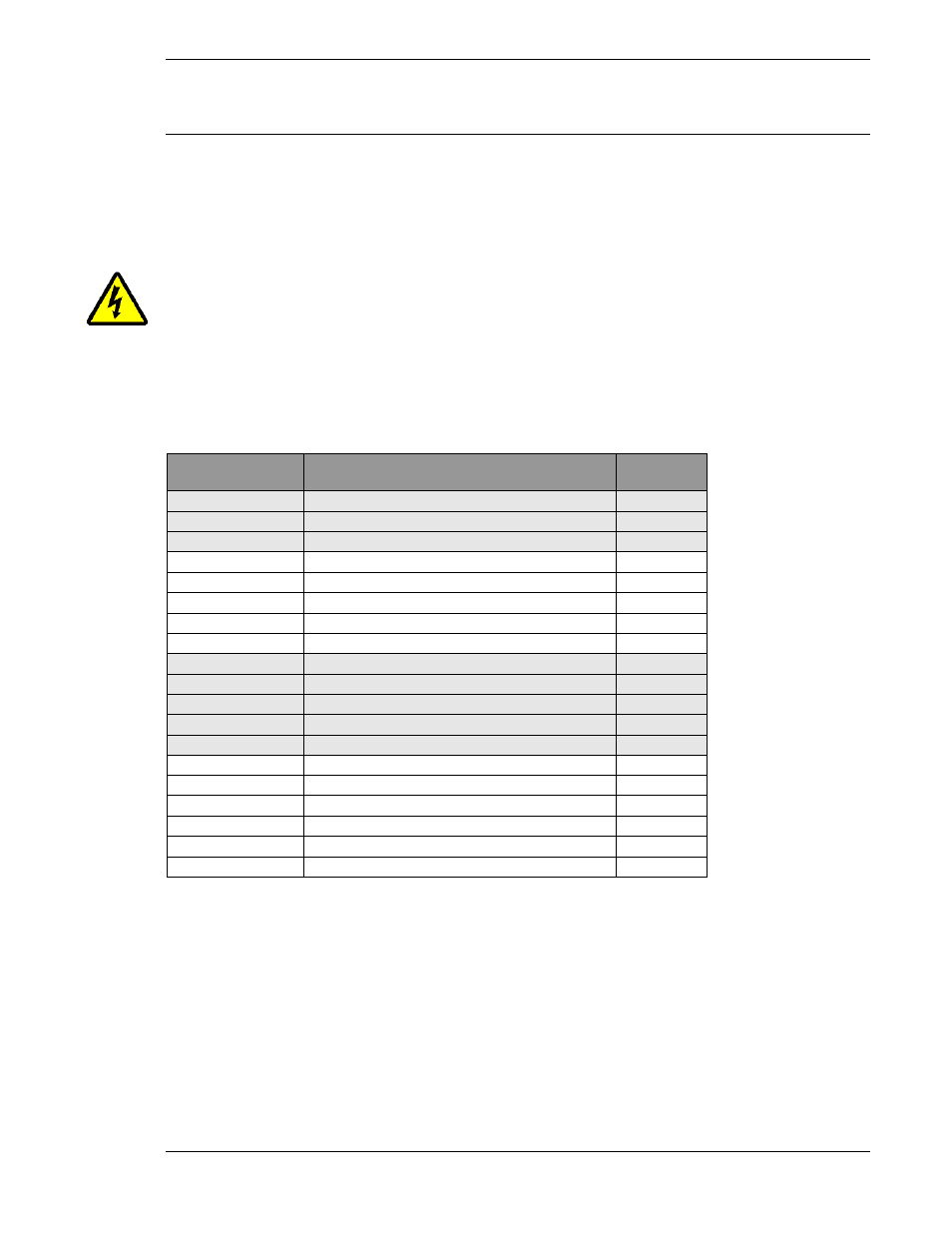

Fusion Cable List

FEC Part #

FEB-1309-M5

Main Cable Straight Female Plug

FEB-1309-M10

Main Cable Straight Female

FEB-1309-M15

Main Cable Straight Female Plug

FEB-1311-M5

Main Cable 90 Degree Female Plug

FEB-1311-M10

Main Cable 90 Degree Female Plug

FEB-1311-M15

Main Cable 90 Degree Female Plug

FEB-1310-M1

Extension Cable Straight Female Plug

FEB-1310-M2

Extension Cable Straight Female Plug

FEB-1310-M3

Extension Cable Straight Female Plug

FEB-1310-M5

Extension Cable Straight Female Plug

FEB-1310-M10

Extension

FEB-1312-M1

Extension Cable 90

FEB-1312-M2

Extension Cable 90

FEB-1312-M3

Extension Cable 90

FEB-1312-M5

Extension Cable 90

FEB-1312-M10

Extension Cable 90

Wave Washer (Part # WAV

sired. The washer must be split and inserted by threading the washer

ers.

FEC FUSION Operations Manual

Chapter 4: System Setup and Wiring (Rev. 2.1)

Page 4-29

Connection

Tools are connected to the controller using one cable. One cable connects to the

and resolver. Each cable should be labeled with a specific

number and should be connected to the corresponding controller and

supported to reduce fatigue points. Cable tie points should be loose enough to

allow the cable to move, but yet hold it in place. Cable tie points that are too tight cause a stress

point leading to premature cable failure.

Do not make motor connections with the power on. Turn off all controller power

before attempting to connect or disconnect any motor cables

or tool damage may occur.

able length: 75’ or less.

100’ (must be free from Electrical Noise)

Cable Description

Length

Main Cable Straight Female Plug

5 meter

Main Cable Straight Female Plug

10 meter

Main Cable Straight Female Plug

15 meter

Main Cable 90 Degree Female Plug

5 meter

Main Cable 90 Degree Female Plug

10 meter

Main Cable 90 Degree Female Plug

15 meter

Extension Cable Straight Female Plug

1 meter

Extension Cable Straight Female Plug

2 meter

Extension Cable Straight Female Plug

3 meter

Extension Cable Straight Female Plug

5 meter

Extension Cable Straight Female Plug

10 meter

Extension Cable 90 Degree Female Plug

1 meter

Extension Cable 90 Degree Female Plug

2 meter

Extension Cable 90 Degree Female Plug

3 meter

Extension Cable 90 Degree Female Plug

5 meter

Extension Cable 90 Degree Female Plug

10 meter

Wave Washer (Part # WAV-25036) can be used to tighten the tool side twist lock connector is d

sired. The washer must be split and inserted by threading the washer underneath the twist lock rol

Chapter 4: System Setup and Wiring (Rev. 2.1)

cable. One cable connects to the torque trans-

specific spindle or identi-

and tool.

should be loose enough to

too tight cause a stress

Do not make motor connections with the power on. Turn off all controller power

or tool damage may occur.

25036) can be used to tighten the tool side twist lock connector is de-

underneath the twist lock roll-