1 fieldbus interfaces – profibus-dp – FEC FUSIONE-HS-2 User Manual

Page 77

FEC FUSION Operations Manual

Chapter 4: System Setup and Wiring (Rev. 2.1)

Page 4-39

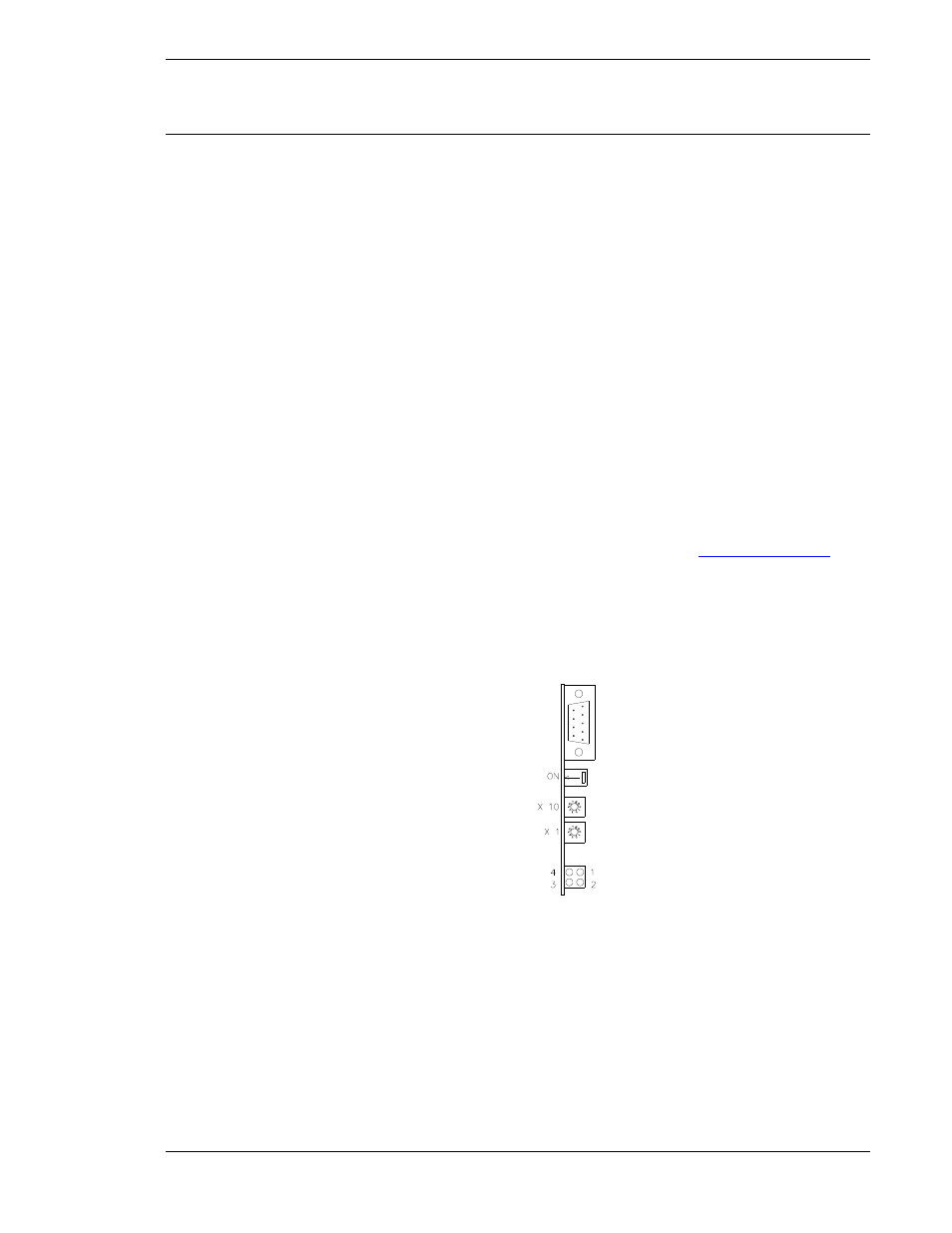

PROFIBUS

CONNECTOR

TERMINATION

SWITCH

ADDRESS

SETTING

LED

INDICATORS

4.15.1 Fieldbus Interfaces – Profibus-DP

The Profibus-DP communication interface allows slave connection to an industrial Profibus-

DP network. Profibus-DP allows industrial devices to be controlled over an open network ar-

chitecture enabling device connection at various locations in the field. This “Fieldbus” tech-

nology reduces hardwiring/cabling & provides ease of installation. It can interface to many

devices such as limit switches, sensors, directional valves, motor starters, bar code readers,

process sensors, frequency drives, etc. The network can have up to 126 nodes. Its maxi-

mum communication baud rate is 12M baud and its minimum baud rate is 9.6K baud.

Node addressing is selectable using the address selection switch. Baud rate is auto detected

from the master and no user setup is required. Module & Network status LED’s provide net-

work diagnostics.

Maximum I/O data is pre-configured for the FUSION system. FEC uses 16 Bytes (128bits)

for Fusion OUTPUTS (Fusion to PLC) which includes Binary Integer output of both Fastening

Torque & Angle. Fusion INPUTS (PLC to Fusion) uses 4 Bytes (32 bits). The I/O signal map

defines what signals/data for each address. (See below)

Note: The Profibus-DP interface is implemented according to the Profibus-DP EN 50 170

(DIN 19245 Part 1) specification.

FEC integrates the Profibus-DP board manufactured by HMS Fieldbus Systems AB into the

Fusion modular I/O board. For further technical information on the Profibus-DP interface go

to the HMS website. (www.hms.se)

Further Profibus information can be found on the Profibus website at

www.profibus..com

.

Profibus Interface Board