FEC FUSIONE-HS-2 User Manual

Page 171

FUSION Operations Manual

9.2

Torque Transducer Abnormals

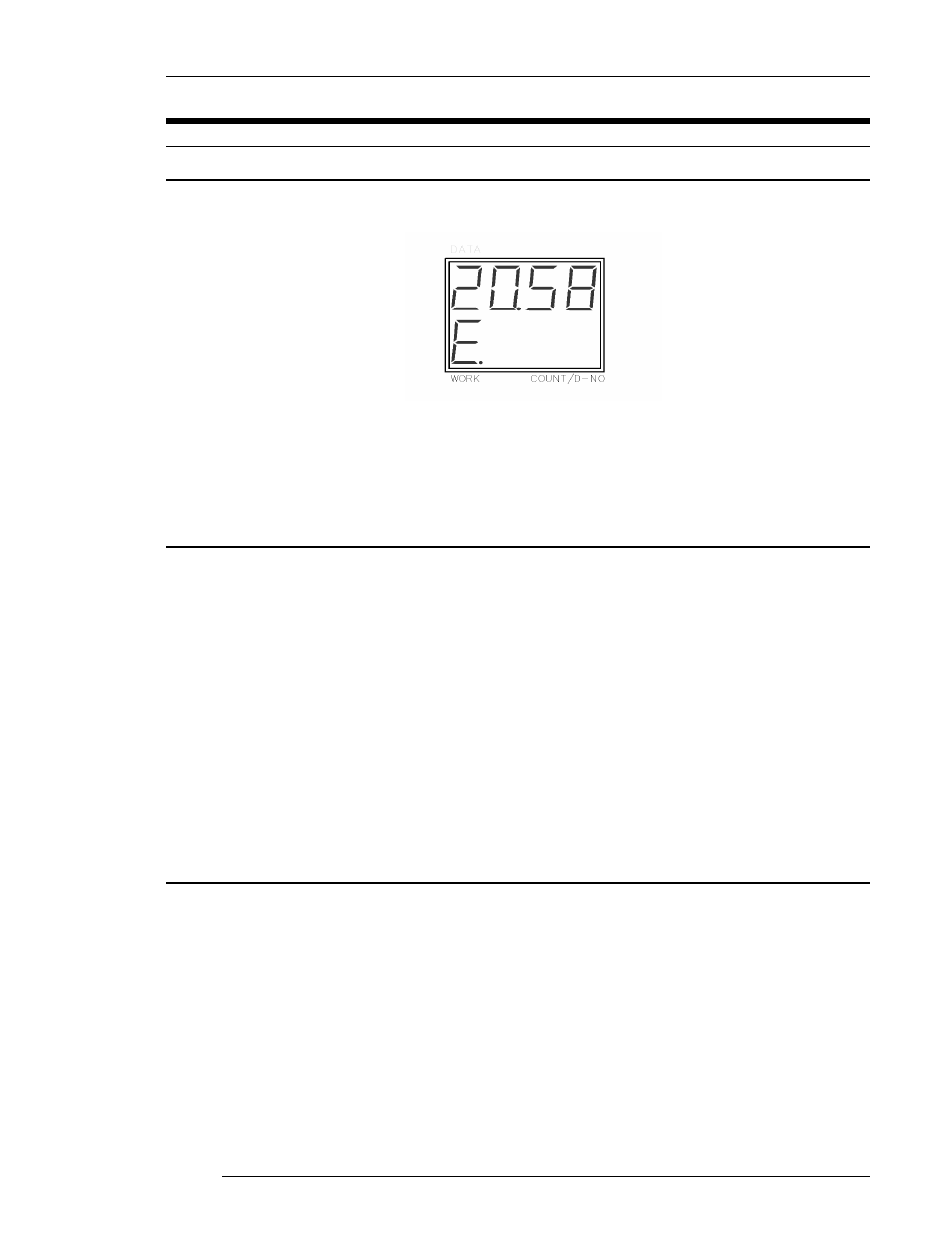

Calibration Error

When the CAL switch is pressed

preset value is missing or a wrong tool is connected

RECOVERY:

1. Program correct Full Scale Preset value for the tool connected

2. Exchange tool cable, tool and/or co

system after each exchange, and make note of any change in the location of the a

normal.

3. Replace the defective component.

9.2.1

Code 1-0 TORQUE TRANSDUCER / ZERO VOLTAGE ERROR

Zero level does not match

tion.

This abnormal is caused from;

1. When the tool transducer is sensing excessive torque due to pressure on the tool body.

2. If the controller or the transducer cable is located in an elect

3. When the torque transducer,

RECOVERY:

1. Check that the tool has no

has occurred with the tool assembly)

2. Verify that the cable or

sources. Relocate as required and reinitialize.

3. Exchange tool cable, tool and/or controller with known working units. Reinitialize the sy

tem after each exchange, a

4. Replace the defective component.

9.2.2

Code 1-1 TORQUE TRANSDUCER / CAL VOLTAGE ERROR

Calibration voltage error during power on initialization.

This abnormal is caused from;

1. When the tool transducer is sensing excessive torque due to pressure on the tool body.

2. If the controller or the transducer cable is located in an electric or magnetic noise field.

3. When the torque transducer,

RECOVERY:

1. Check that the tool has no signs of an external force being applied to it. (No heavy impact

has occurred with the tool assembly)

2. Verify that the cable or

sources. Relocate a

3. Exchange tool cable,

tem after each exchange, and make note of any change in the location of the abnormal.

4. Replace the defective component.

FUSION Operations Manual Chapter 9: Troubleshooting (Rev. 2)

Page 9-3

Torque Transducer Abnormals

CAL switch is pressed on the Fusion front panel, "

E

" is shown if the FULL

preset value is missing or a wrong tool is connected.

Program correct Full Scale Preset value for the tool connected

Exchange tool cable, tool and/or controller with known working units. Reinitialize the

system after each exchange, and make note of any change in the location of the a

Replace the defective component.

0 TORQUE TRANSDUCER / ZERO VOLTAGE ERROR

Zero level does not match master level read from tool EEPROM during power on initializ

This abnormal is caused from;

1. When the tool transducer is sensing excessive torque due to pressure on the tool body.

2. If the controller or the transducer cable is located in an electric or magnetic noise field.

3. When the torque transducer, Tool cable or the controller malfunctions.

1. Check that the tool has no signs of an external force being applied to it. (

the tool assembly)

fy that the cable or controller is not located near any high voltage transient power

sources. Relocate as required and reinitialize.

cable, tool and/or controller with known working units. Reinitialize the sy

tem after each exchange, and make note of any change in the location of the abnormal.

4. Replace the defective component.

1 TORQUE TRANSDUCER / CAL VOLTAGE ERROR

Calibration voltage error during power on initialization.

This abnormal is caused from;

transducer is sensing excessive torque due to pressure on the tool body.

2. If the controller or the transducer cable is located in an electric or magnetic noise field.

3. When the torque transducer, Tool cable or the controller malfunctions.

1. Check that the tool has no signs of an external force being applied to it. (No heavy impact

has occurred with the tool assembly)

2. Verify that the cable or controller is not located near any high voltage transient power

sources. Relocate as required and reinitialize.

Exchange tool cable, tool and/or controller with known working units. Reinitialize the sy

tem after each exchange, and make note of any change in the location of the abnormal.

4. Replace the defective component.

Chapter 9: Troubleshooting (Rev. 2)

" is shown if the FULL-SCALE

ntroller with known working units. Reinitialize the

system after each exchange, and make note of any change in the location of the ab-

0 TORQUE TRANSDUCER / ZERO VOLTAGE ERROR

master level read from tool EEPROM during power on initializa-

1. When the tool transducer is sensing excessive torque due to pressure on the tool body.

ric or magnetic noise field.

or the controller malfunctions.

applied to it. (No heavy impact

not located near any high voltage transient power

cable, tool and/or controller with known working units. Reinitialize the sys-

nd make note of any change in the location of the abnormal.

transducer is sensing excessive torque due to pressure on the tool body.

2. If the controller or the transducer cable is located in an electric or magnetic noise field.

or the controller malfunctions.

1. Check that the tool has no signs of an external force being applied to it. (No heavy impact

not located near any high voltage transient power

tool and/or controller with known working units. Reinitialize the sys-

tem after each exchange, and make note of any change in the location of the abnormal.