Dip switch setting, I/o signal map – FEC FUSIONE-HS-2 User Manual

Page 84

Chapter 4: System Setup and Wiring

Page 4-46

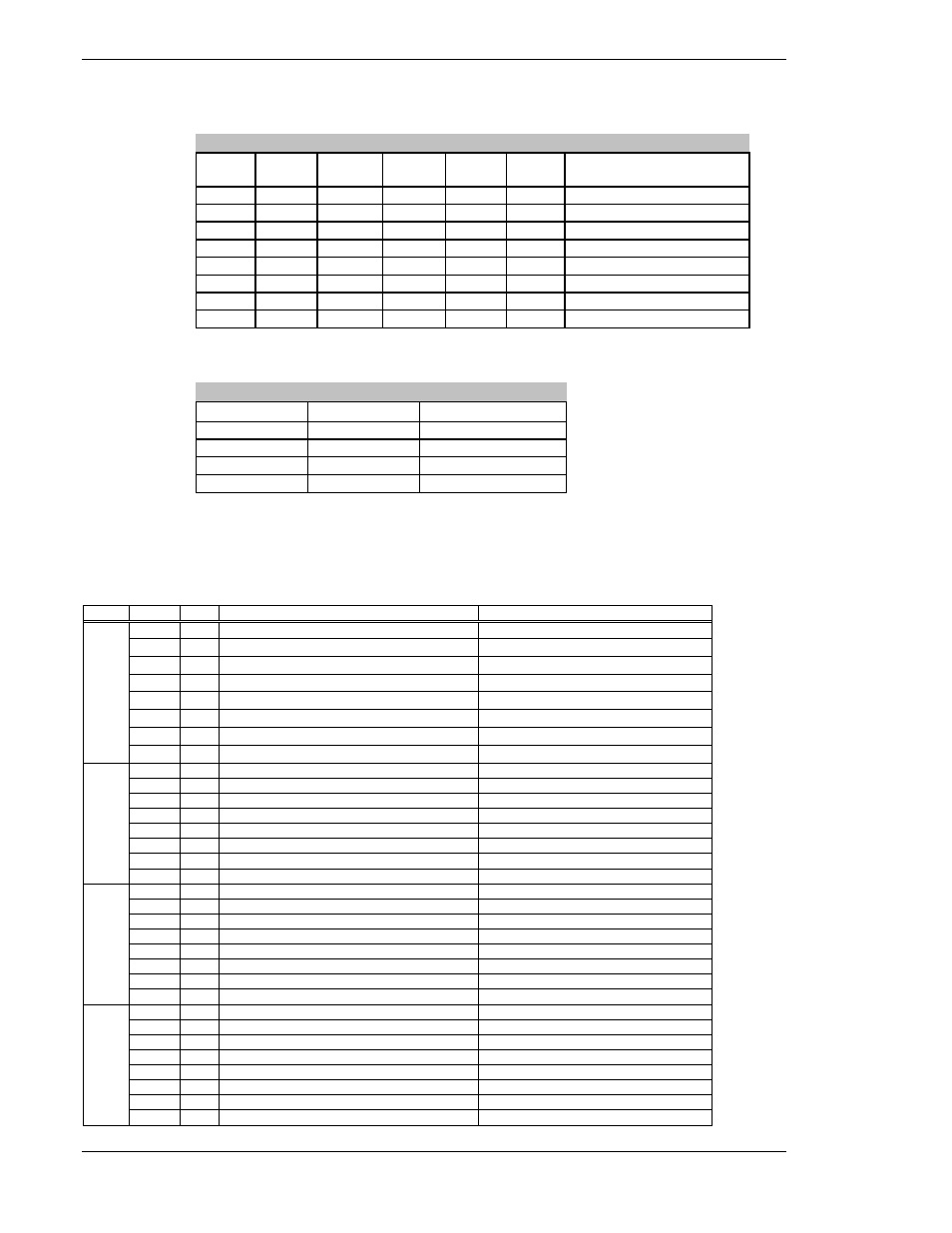

Dip Switch Setting

Address setting (DIP switch)

SW-3

(LSB)

SW-4

SW-5

SW-6

SW-7

SW-8

MAC ID

OFF

OFF

OFF

OFF

OFF

OFF

Address 0*

ON

OFF

OFF

OFF

OFF

OFF

Address 1

OFF

ON

OFF

OFF

OFF

OFF

Address 2

ON

ON

OFF

OFF

OFF

OFF

Address 3

.

.

.

.

.

.

.

ON

OFF

OFF

ON

ON

ON

Address 57

OFF

ON

OFF

ON

ON

ON

Address 58

ON

ON

OFF

ON

ON

ON

Address 59

This switch must be set before power is on, and cannot be changed during operation.

*Address should be set to “0” if this is the only device on the network.

Baud rate setting (DIP switch)

SW-1

SW-2

Baud rate

OFF

OFF

57.6K

ON

OFF

115K

OFF

ON

230K

ON

ON

Reserved

Baud rate must match the settings of the Remote I/O scanner.

This switch must be set before power is on, and cannot be changed during operation.

I/O Signal Map

From Fusion to PLC – (4 Bytes – 32 Bits)

Octal

Bit

Signal Description

Comment

I:00

0

0

End

1

1

Accept

2

2

Reject

3

3

4

4

5

5

Job Cycle Accepted

Future

6

6

Job Done Status Aborted

Future

7

7

I:00

10

8

11

9

12

10

Time 1 Reject

13

11

Time 2 Reject

14

12

Work Select Bit 0 / Job Bit 0 (echo)

Job Function is Future

15

13

Work Select Bit 1 / Job Bit 1 (echo)

Job Function is Future

16

14

Work Select Bit 2 / Job Bit 2 (echo)

Job Function is Future

17

15

Work Select Bit 3 / Job Bit 3 (echo)

Job Function is Future

I:01

0

0

Reject

1

1

Accept

2

2

Abnormal

3

3

Ready

4

4

Busy

5

5

Torque High Reject

6

6

Torque Low Reject

7

7

Bypass

I:01

10

8

Angle High Reject

11

9

Angle Low Reject

12

10

Rate1 High Reject

13

11

Rate1 Low Reject

14

12

Rate2 High Reject

15

13

Rate2 Low Reject

16

14

Rate3 High Reject

17

15

Rate3 Low Reject