FEC FUSIONE-HS-2 User Manual

Page 170

Chapter 9: Troubleshooting

Page 9-2

9.1 Abnormal Conditions.

When an abnormal condition is detected by the system, the affected spindle stops, and lights

“Abn” in the [DATA] display. For ease of troubleshooting the nature of the abnormal, the sys-

tem provides an abnormal code in the [PARM] display and an abnormal sub-code in the

[COUNT/D-NO] display.

Note: ABNORMALS are not to be confused with fastening REJECTS. Abnormal’s signify a

failure of a system process or self check during the fastening cycle.

•

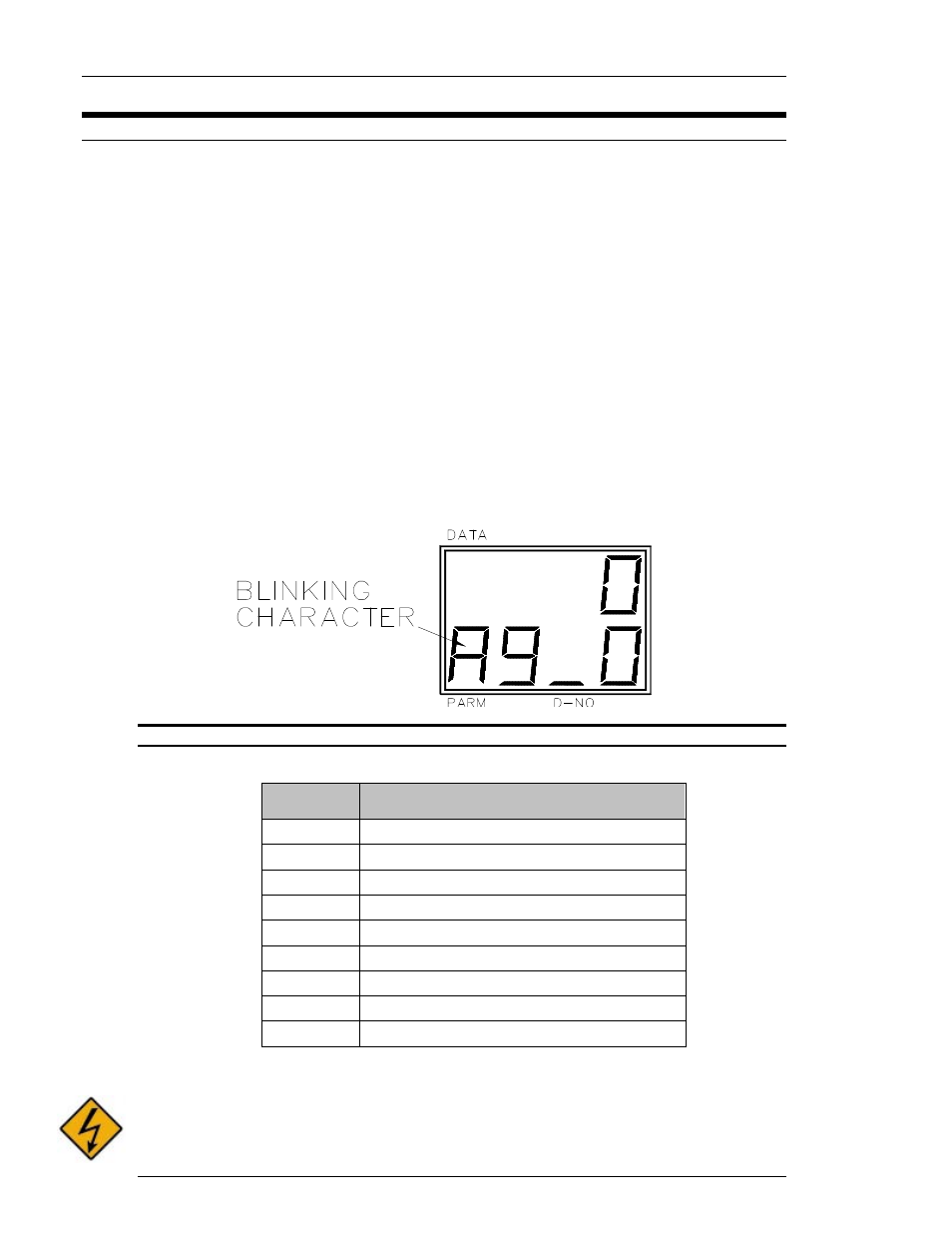

Abnormal code display

.

When an Abnormal condition occurs, the display mode will automatically change to the

STATUS mode. (If the display is not in the STATUS mode, depress the MODE button until a

blinking “A” appears in the [WORK] display area) A code number appears at the right side of

the blinking character. This code refers to some specific type of failure detailed in the tables

shown in the following sections.

•

Abnormal Sub-code display

.

The number shown at the most right position in the [COUNT/D-NO] display area is a sub-

code that can be used in conjunction with the Abnormal failure code to further narrow down

the cause of the fault. See the following sections.

Example of Abnormal Code 9 Sub-Code 0

Abnormal Code Table

ABNORMAL

CODE

DESCRIPTION

1

Torque Transducer Error.

2

Over Torque Error.

3

Tool EEPROM error.

4

System Memory Error.

5

Servo Amplifier Reply Error.

6

Servo Type Mismatch Error.

7

NOT USED

8

Servo Amplifier Error.

9

Parameter Error.

Abnormal sub-codes and specific actions for troubleshooting are detailed in the following

section.

WARNING:DO NOT CONNECT OR DISCONNECT CABLES OR OTHER SYSTEM

COMPONENTS WITH POWER APPLIED.