5 parameter data list & explanation – FEC FUSIONE-HS-2 User Manual

Page 133

FUSION Operations Manual Chapter 7: System Operations (Rev.2)

Page 7-9

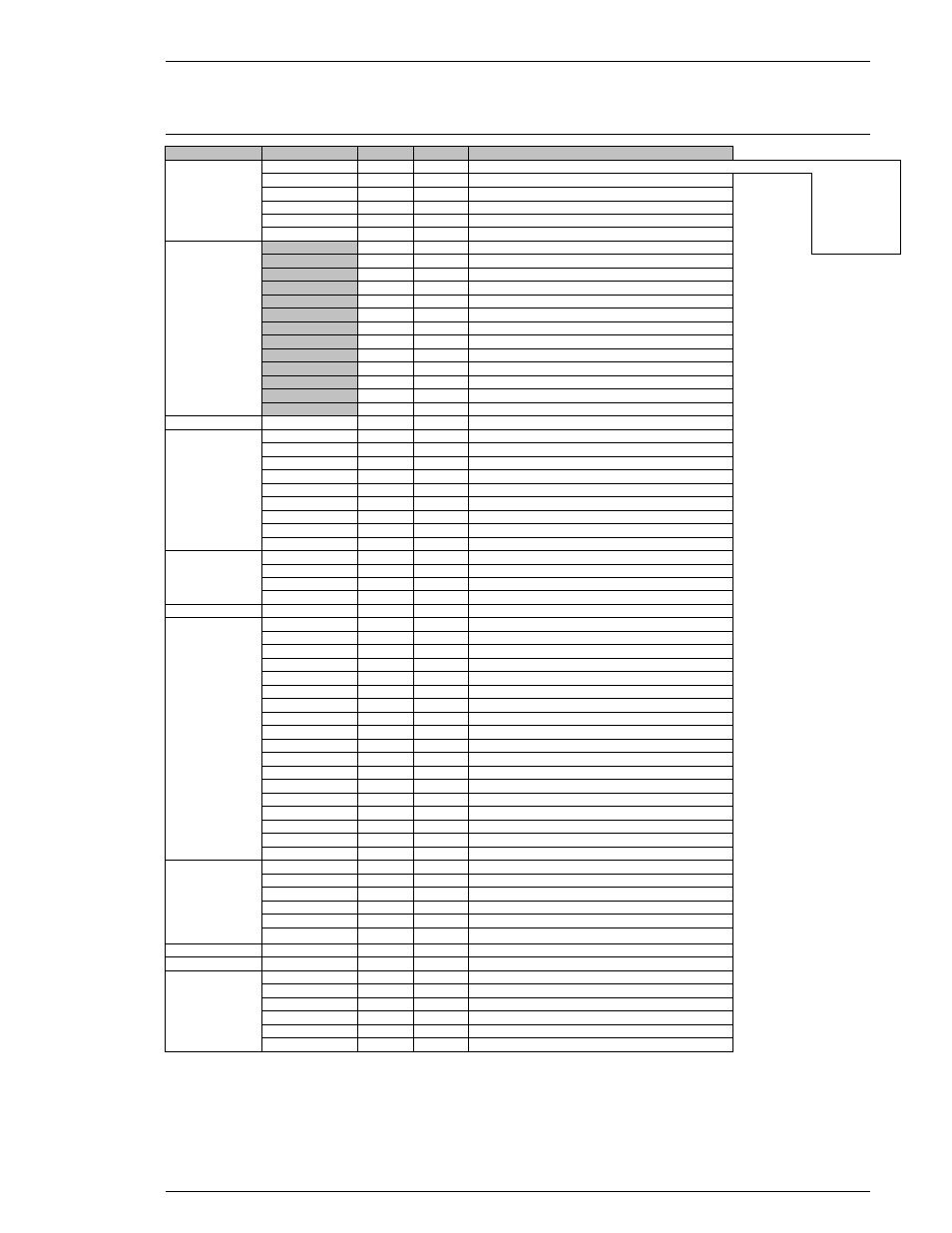

7.2.5 Parameter Data List & Explanation

ITEM

DATA SETTING

WORK

D- No

DATA

System

0

00

TORQUE UNIT #.

0: Nm

0

01

ROM VERSION (Not adjustable)

1: Kg.m

0

02

AMPLIFIER VERSION (Not adjustable)

2: Kgcm

0

03

FASTENING FUNCTION VERSION (1.03 for FEC)

See Pg 7-12

3: Ft lb

0

04

External gear ratio 0.3 ~ 3.00

0

05

Gear Head Type See Pg 7-13

Tool Data

(This section is

factory set and

cannot be

changed)

0

10

TOOL # (not adjustable)

4: in lb

0

11

TOOL CAL TORQUE.

0

12

CAL. VOLTAGE

0

13

ZERO TORQUE VOLTAGE

0

14

PULSES PER DEGREE

0

15

MOTOR TYPE

0

16

TRANSMISSION RATIO

0

17

ROTATE CW=0 / CCW=1

0

18

CCW TQ. CAL. VOLTAGE

0

19

TOOL SERIAL # (1ST 4 DIGITS)

0

1A

TOOL SERIAL # (2ND 4 DIGITS)

0

1b

Tool Cycle count Upper 4 digit

0

1c

Tool Cycle count Lower 4 digit

Tool type

0

20

TOOL #

See List on next pages

Tool Info

0

21

Start switch trigger level

10 Change to 100 to disable

0

22

Start switch High Speed level

40 Change to 100 to disable

0

23

CW/CCW switch trigger level

20

Change to 100 to disable

0

24

Switch setup (Factory setup)

67

0

25

Switch setup (Factory setup)

30

0

26

Switch setup (Factory setup)

1

0

27

Switch setup (Factory setup)

200

0

28

Switch setup (Factory setup)

5

0

29

Switch setup (Factory setup)

80

Real Time Clock

(After ver. 2.20)

0

30

Year – ‘yyyy” example ‘2007’

See 7.5 for detail

0

31

Month & Date ‘mmdd example ‘0131’ = Jan. 31

0

32

Hour & Minute ‘hhmm’ example ‘1759 = 17:59

0

33

Seconds ‘00ss’ example ‘0020’ = 20 seconds

RS232 Format

0

40 - 49

RS232 data alternate communication format

See 4.8.4 for set-up

Torque

1~16

00

FASTENING MODE (METHOD + STEPS)

See List on next pages

1~16

05

OPTION 1-Future use

1~16

06

OPTION 2-Future use

1~16

10

FULL SCALE TORQUE (CAL TORQUE)

+/- 20%

1~16

11

PEAK TORQUE LOW LIMIT

1~16

12

PEAK TORQUE HIGH LIMIT

Max. Full Scale x 1.1

1~16

13

STANDARD (STD) TORQUE

1~16

14

SPEED CHANGE TORQUE

1~16

15

1ST TORQUE

1~16

16

SNUG TORQUE

1~16

17

THRESHOLD (THR) TORQUE

1~16

18

CROSSOVER (CROS) TORQUE

1~16

19

TORQUE INHIBIT LIMIT

Max. Full Scale x 1.1

1~16

1A

Not Used

1~16

1B

BREAKAWAY TORQUE LIMIT

Max. Full Scale x 1.1

1~16

1C

FINAL TORQUE LOW LIMIT

1~16

1D

FINAL TORQUE HIGH LIMIT

Max. Full Scale x 1.1

1~16

1E

2ND RATE START TORQUE

Max. Full Scale x 1.1

Angle

1~16

20

ANGLE LOW LIMIT

1~16

21

ANGLE HIGH LIMIT

Max. 9999 deg

1~16

22

STANDARD (STD) ANGLE

Max. 9999 deg

1~16

23

1ST ANGLE

Max. 9999 deg

1~16

24

CROSSOVER ANGLE

Max. 9999 deg

1~16

25

ANGLE CORRECTION

0-99 deg.

1~16

26

Future use

1~16

27

Future use

Rate

1~16

30

1ST TORQUE RATE LOW LIMIT

For all Rate settings

Max. “5000”

Setting “0000” in any of

The LOW rate settings

disables low rate judgment

1~16

31

1ST TORQUE RATE HIGH LIMIT

1~16

32

2ND TORQUE RATE LOW LIMIT

1~16

33

2ND TORQUE RATE HIGH LIMIT

1~16

34

3RD TORQUE RATE HIGH LIMIT

1~16

35

3RD TORQUE RATE HIGH LIMIT

(Continued on next page)