FEC FUSIONE-HS-2 User Manual

Page 104

Chapter 6: Fastening Instructions

Two-Step Fastening

Two-Step fastening will be used primarily for joints that have a requirement to synchronize

with another spindle during the final stage of the rundown.

1. Angle control commences at SNUG TORQUE. All angle values are referenced from this point.

2. Once SPEED CHANGE TORQUE is reached or FREERUN REVOLUTIONS expires, the system will

switch from FREERUN SPEED to SLOWDOWN SPEED and continue to fasten to 1ST

TORQUE/ANGLE.

3. The system will fasten to the 1ST TORQUE/ANGLE value during the specified 1ST TIME. 1ST

TORQUE/ANGLE must be reached within the 1ST TIME limits or a reject will occur.

4. Upon reaching 1ST TORQUE/ANGLE, 1ST TIME ends and FINAL TIME begins. 1ST

TORQUE/ANGLE is the shift point to TORQUE SPEED

mencing the next step.

(See 4.13

5. The system will fasten to STANDARD ANGLE using TORQUE SPEED during FINAL TIME.

STANDARD ANGLE must be reached within the FINAL TIME lim

NOTE: When performing multiple step Angle control fastening, the rotation Angle

should be performed as one continuous operation. There should be no intermediate

stop / synchronization points once Snug Torque has been sense

being controlled. Under special conditions multiple steps can be performed using i

termediate Torque or Angle stop/synchronization points.

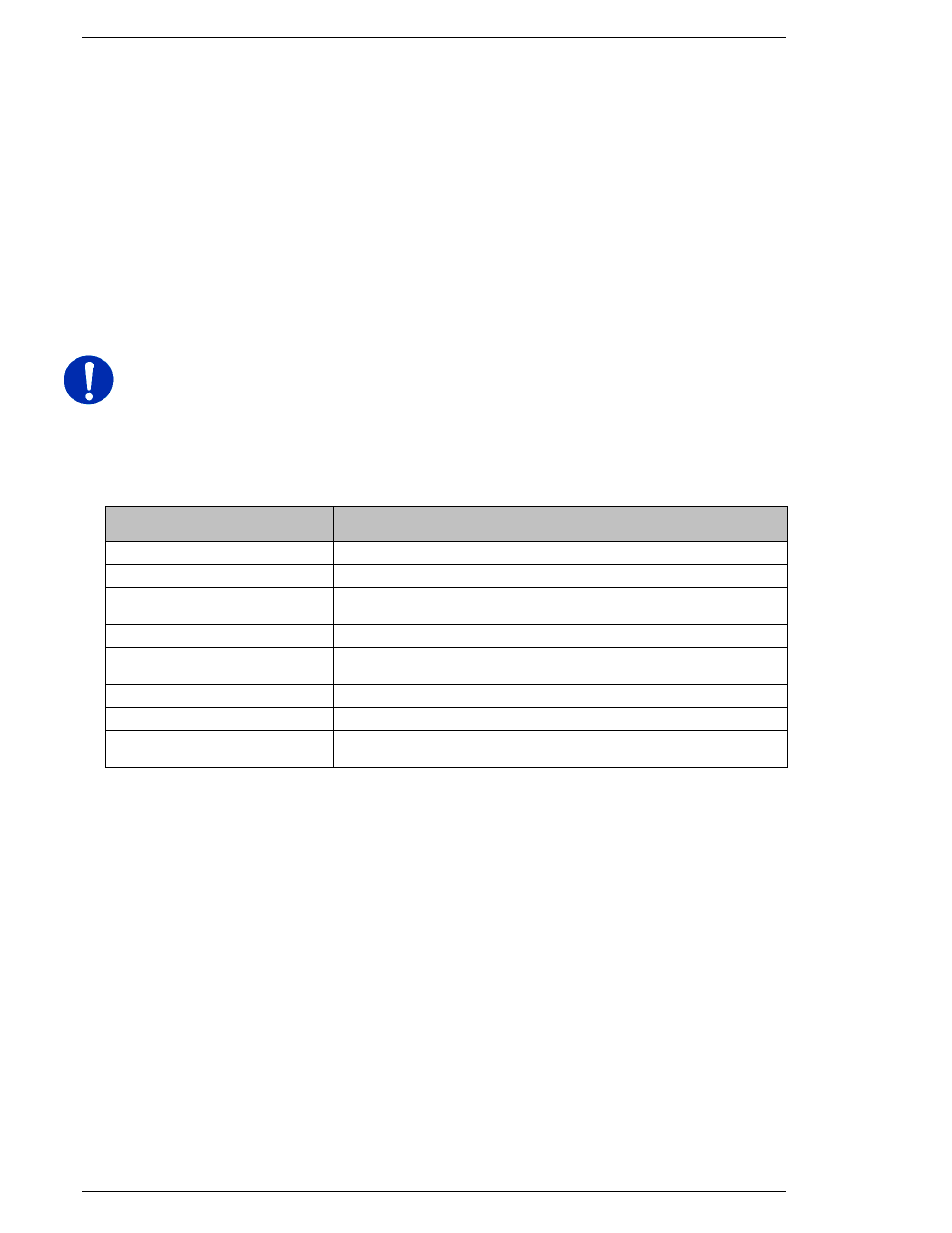

FUNCTION

RECOMMENDATION / COMMENT

SPEED CHANGE TORQUE

30% of S

THRESHOLD TORQUE

Start point of 1

1ST TORQUE/ANGLE

80% of S

Used for RATE/TIME settings and TORQUE SPEED initiation.

SNUG TORQUE

Angle Control Start Point

CROSSOVER

TORQUE/ANGLE

Start point of 3

STANDARD ANGLE

Engineered product fastening specification

1ST TIME HIGH/LOW LIMIT

Acceptance range to reach 1ST TORQUE

FINAL TIME HIGH/LOW LIMIT Acceptance range to go from 1ST TORQUE

STANDARD

Page 6-8

Step fastening will be used primarily for joints that have a requirement to synchronize

with another spindle during the final stage of the rundown.

nces at SNUG TORQUE. All angle values are referenced from this point.

Once SPEED CHANGE TORQUE is reached or FREERUN REVOLUTIONS expires, the system will

switch from FREERUN SPEED to SLOWDOWN SPEED and continue to fasten to 1ST

will fasten to the 1ST TORQUE/ANGLE value during the specified 1ST TIME. 1ST

TORQUE/ANGLE must be reached within the 1ST TIME limits or a reject will occur.

Upon reaching 1ST TORQUE/ANGLE, 1ST TIME ends and FINAL TIME begins. 1ST

hift point to TORQUE SPEED and the synchronization point prior to co

13 for Sync. info)

.

The system will fasten to STANDARD ANGLE using TORQUE SPEED during FINAL TIME.

STANDARD ANGLE must be reached within the FINAL TIME limits or a reject will occur.

NOTE: When performing multiple step Angle control fastening, the rotation Angle

should be performed as one continuous operation. There should be no intermediate

stop / synchronization points once Snug Torque has been sensed and rotation angle is

being controlled. Under special conditions multiple steps can be performed using i

termediate Torque or Angle stop/synchronization points.

RECOMMENDATION / COMMENT

% of SNUG TORQUE

Start point of 1

st

torque rate monitoring (section 6.2)

% of SNUG TORQUE

Used for RATE/TIME settings and TORQUE SPEED initiation.

Angle Control Start Point

Start point of 3

RD

torque rate monitoring (section 6.2)

Engineered product fastening specification

Acceptance range to reach 1ST TORQUE/ANGLE setting

Acceptance range to go from 1ST TORQUE/ANGLE to

STANDARD ANGLE

Step fastening will be used primarily for joints that have a requirement to synchronize

nces at SNUG TORQUE. All angle values are referenced from this point.

Once SPEED CHANGE TORQUE is reached or FREERUN REVOLUTIONS expires, the system will

will fasten to the 1ST TORQUE/ANGLE value during the specified 1ST TIME. 1ST

and the synchronization point prior to com-

The system will fasten to STANDARD ANGLE using TORQUE SPEED during FINAL TIME.

NOTE: When performing multiple step Angle control fastening, the rotation Angle

should be performed as one continuous operation. There should be no intermediate

d and rotation angle is

being controlled. Under special conditions multiple steps can be performed using in-

Used for RATE/TIME settings and TORQUE SPEED initiation.

setting

to