FEC FUSIONE-HS-2 User Manual

Page 130

Chapter 7: System Operations

7.2.2 Real-time display indication mode.

While the mode is in

Real time display mode

choose the desired type of data by pressing the [

NO] (data number). The indicator will display the following data in the "DATA" area for the

selected D-No. The display will remain showing the parameter number.

The Controller will be in

Real time display mode

Once a fastening cycle has been performed the Controller will switch to

display mode. Real time display mode

by pressing the MODE push-button.

in Fig. 7-2-2.

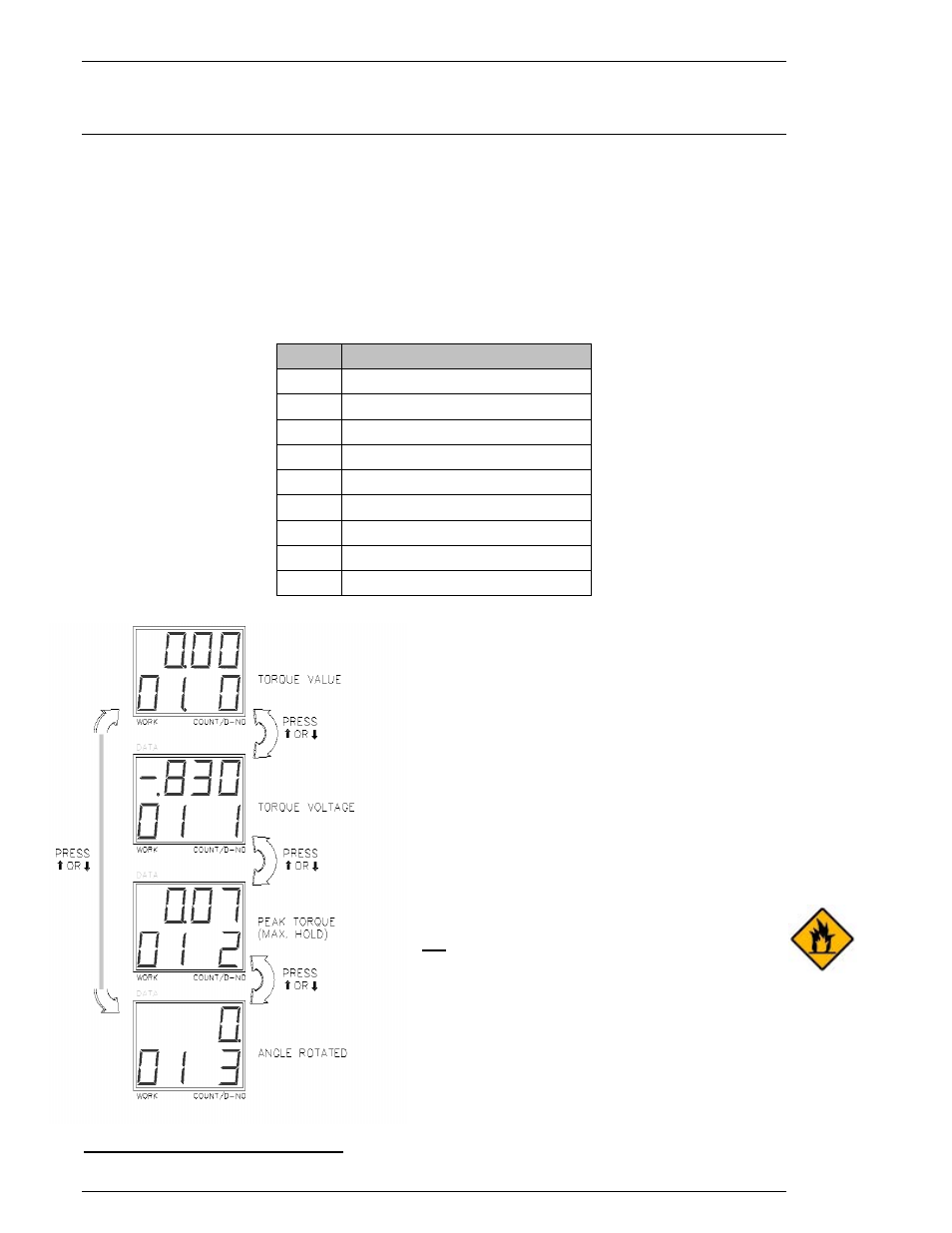

FIG. 7-2-2 Real time display selection

D-No DATA

0

Torque value.

1

Torque voltage.

2

Peak Torque (maximum hold).

3

Rotated Angle.

4

Thermal Overload Value 0

5

Current Sensor Value

6

Start Trigger Level 127

7

Re

8

FEC specific data

Page 7-6

time display indication mode.

Real time display mode

, [COUNT/D-NO] displays

0 ~8.

You can

choose the desired type of data by pressing the [

↓↓↓↓

] and [

↑↑↑↑

] keys to change the [COUNT/D

(data number). The indicator will display the following data in the "DATA" area for the

will remain showing the parameter number.

Real time display mode

immediately after powering up the unit.

Once a fastening cycle has been performed the Controller will switch to

Fastening results

display mode. Real time display mode

can be selected at any time, while in the RUN state

button. Button operation during the real-time mode is indicated

Torque value:

The real-time torque value from the

torque transducer is displayed.

Torque voltage:

The real-time torque signal voltage

from the torque transducer is displayed.

Peak torque:

The peak torque, measured since the

last time the display mode was switched to Real

Time Display Mode. (This is reset when the display

mode is changed from the Real Time Display

Mode.)

Lock Spindle Mode :

When [SET] is depressed

during this display, the motor is locked for up to one

minute allowing the spindle to be checked with a

torque wrench while displaying the reaction torque

on the data display. Press RESET to unlock the M

tor before one minute has expired.

WARNING

not repeat this procedure repetitively or the m

tor will overheat.

Angle (rotation):

The real-time angle of rotation of

the tool output shaft (in the fastening direction CW),

measured since the last time the display mode was

switched to Real Time Display Mode.

(-1999

°

to 9999

°

)

Thermal Overload Level:

Between 0 -100

(100=overload)

DATA

Torque value.

Torque voltage.

Peak Torque (maximum hold).

Rotated Angle.

Thermal Overload Value 0-100

Current Sensor Value

Start Trigger Level 127-255

Reverse Button Level 127-255

FEC specific data

You can

[COUNT/D-

(data number). The indicator will display the following data in the "DATA" area for the

the unit.

Fastening results

can be selected at any time, while in the RUN state

time mode is indicated

time torque value from the

time torque signal voltage

The peak torque, measured since the

last time the display mode was switched to Real

Time Display Mode. (This is reset when the display

mode is changed from the Real Time Display

] is depressed

ing this display, the motor is locked for up to one

minute allowing the spindle to be checked with a

torque wrench while displaying the reaction torque

. Press RESET to unlock the Mo-

RNING

:

Do

repeat this procedure repetitively or the mo-

time angle of rotation of

the tool output shaft (in the fastening direction CW),

measured since the last time the display mode was

100