FEC FUSIONE-HS-2 User Manual

Page 38

Chapter 3: System Description

Page 3-8

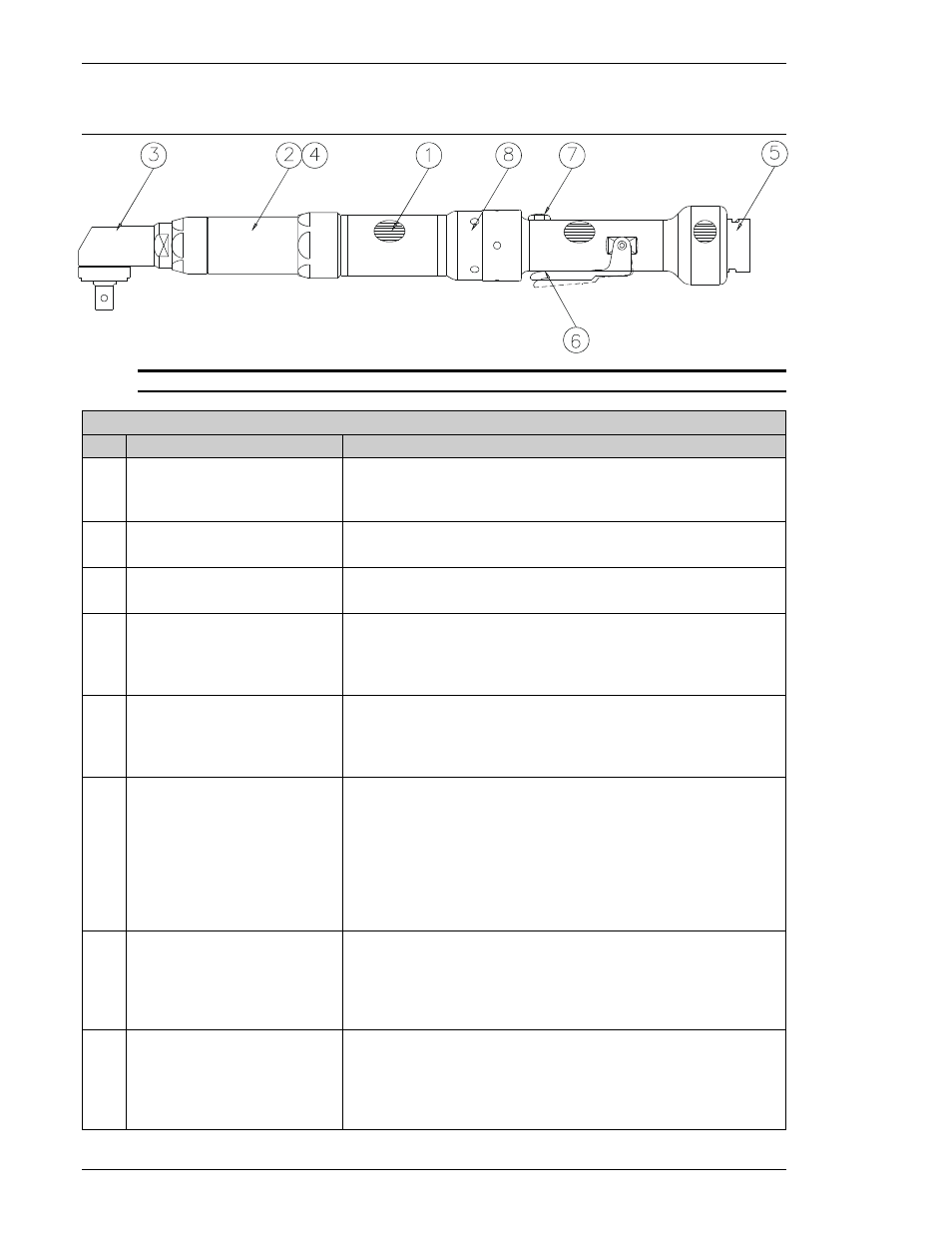

3.2.2 FUSION Tool Control, Displays and Connectors

Fig. 3.2.2 Tool Description

TOOL MAJOR COMPONENT IDENTIFICATION

ITEM ITEM AS MARKED ON UNIT

DESCRIPTION

1 MOTOR / RESOLVER

Provides feedback for speed regulation to the Servo Amplifier.

Provides angular rotation monitoring for fastening operation.

Totally enclosed DC permanent magnet motor.

2 TRANSMISSION

Durable planetary gear transmission.

Refer to Chapter 2 for standard tools and gear ratios.

3 ANGLE HEAD

Durable right angle head.

Refer to Chapter 2 for standard tools and gear ratios.

4 TRANSDUCER / PREAMP

Highly accurate strain gage transducer.

Highly durable, compact design minimizes space requirements.

Intelligent transducer design uses an “ID Chip” to verify

integrity of fastening operations.

5 CABLE CONNECTOR

Twist lock single connector for tool cable connection. Twist

lock type connector can be connected and disconnected by

twisting the outside ring 90 degrees clockwise and counter

clockwise respectively.

6 START SWITCH

Variable speed start switch. Depressing the Start switch

partially initiates a manually controlled slow speed start.

Depressing the Start switch fully initiate a fastening cycle as

programmed into the controller. Releasing the Start switch at

any time terminates the fastening operation.

Used to initiate a reverse tool operation when in

Reverse/Backout mode.

7 REVERSE SWITCH

Momentary Reverse selector switch. Depressing the Reverse

selector switch places the tool in the Reverse/Backout mode.

The Accept/Reject LED display on the tool flashes to indicate

Reverse operation selection. Depressing the Reverse selector

switch again, places the tool back in the fastening mode.

8 LED DISPLAY RING

360 degree LED display ring.

Green indicates an accept condition.

Red indicates a Reject condition.

Flashing Red and Green indicate Reverse/Backout mode.

Solid Red and Green during power on for verification.