Profibus signal i/o map – FEC FUSIONE-HS-2 User Manual

Page 80

Chapter 4: System Setup and Wiring

Page 4-42

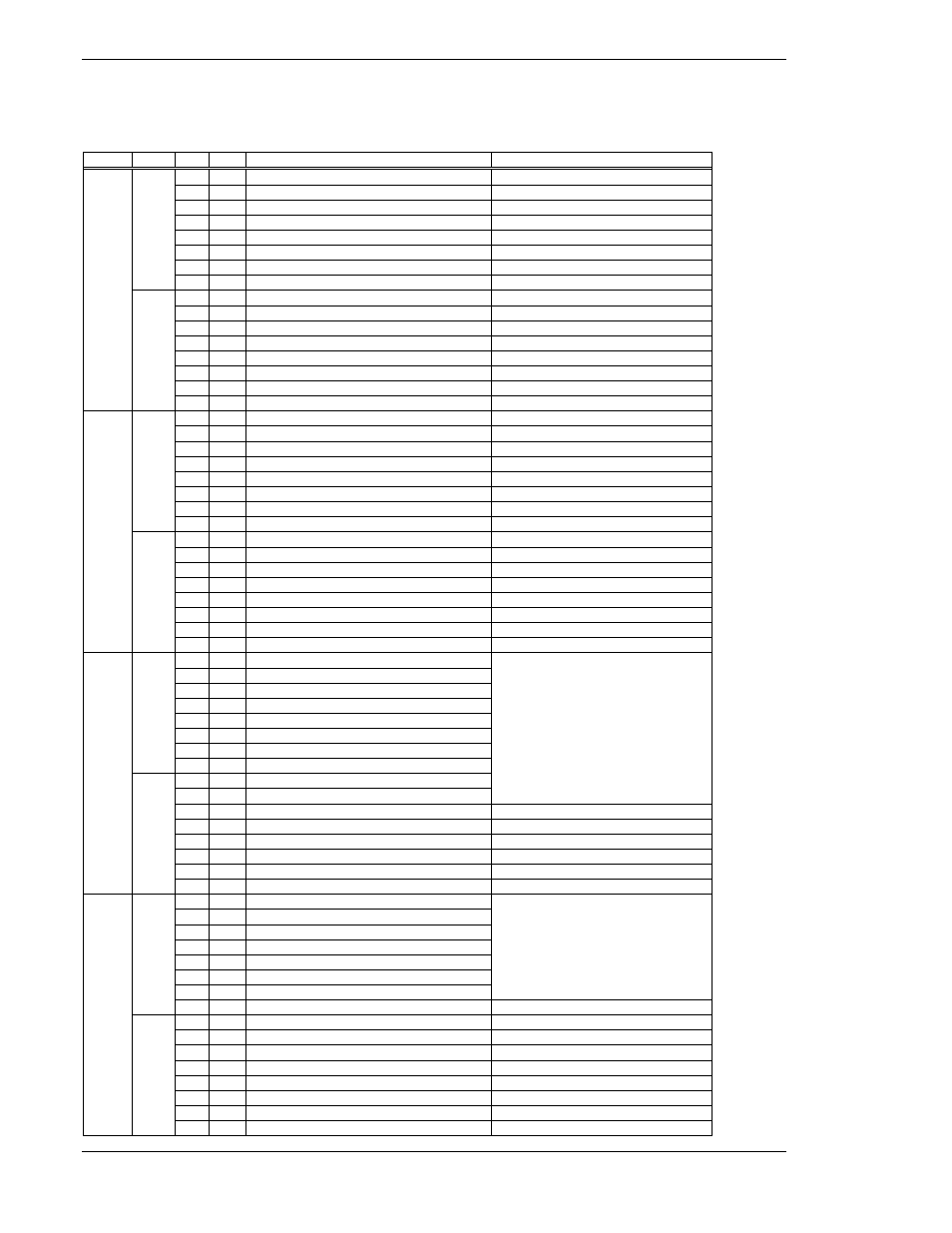

Profibus Signal I/O Map

From Fusion to PLC : 8 Words (16 Bytes – 128 Bits)

Word Byte Bit No.

Signal Description

Comment

0

0

0

1

End

1

2

Accept

2

3

Reject

3

4

4

5

5

6

Job Cycle Accepted

Future

6

7

Job Done Status Aborted

Future

7

8

1

0

9

1

10

2

11

Time 1 Reject

3

12

Time 2 Reject

4

13

Work Select Bit 0 / Job Bit 0 (echo)

Job Function is Future

5

14

Work Select Bit 1 / Job Bit 1 (echo)

Job Function is Future

6

15

Work Select Bit 2 / Job Bit 2 (echo)

Job Function is Future

7

16

Work Select Bit 3 / Job Bit 3 (echo)

Job Function is Future

1

2

0

17

Reject

1

18

Accept

2

19

Abnormal

3

20

Ready

4

21

Busy

5

22

Torque High Reject

6

23

Torque Low Reject

7

24

Bypass

3

0

25

Angle High Reject

1

26

Angle Low Reject

2

27

Rate1 High Reject

3

28

Rate1 Low Reject

4

29

Rate2 High Reject

5

30

Rate2 Low Reject

6

31

Rate3 High Reject

7

32

Rate3 Low Reject

2

4

0

33

Torque Integer bit 0

Outputs Fastening Torque using bi-

nary integer

0 - 999 max.

(number LEFT of decimal only)

Example:

bit 2, 4, 7 Logical "1" = 148

Total Torque including Torque de-

cimal (word3) = 148.38

1

34

Torque Integer bit 1

2

35

Torque Integer bit 2

3

36

Torque Integer bit 3

4

37

Torque Integer bit 4

5

38

Torque Integer bit 5

6

39

Torque Integer bit 6

7

40

Torque Integer bit 7

5

0

41

Torque Integer bit 8

1

42

Torque Integer bit 9

2

43

3

44

4

45

5

46

6

47

7

48

3

6

0

49

Torque Decimal bit 0

Outputs Fastening Torque Decimal

value using binary integer

0 - 99 max.

(number RIGHT of decimal only)

Example:

bit 1, 2, 5 Logical "1" = 38

1

50

Torque Decimal bit 1

2

51

Torque Decimal bit 2

3

52

Torque Decimal bit 3

4

53

Torque Decimal bit 4

5

54

Torque Decimal bit 5

6

55

Torque Decimal bit 6

7

56

7

0

57

1

58

2

59

3

60

4

61

5

62

6

63

7

64