FEC FUSIONE-HS-2 User Manual

Page 121

FEC Fusion Operations Manual Chapter 6: Fastening Instructions (Rev. 2)

Page 6-25

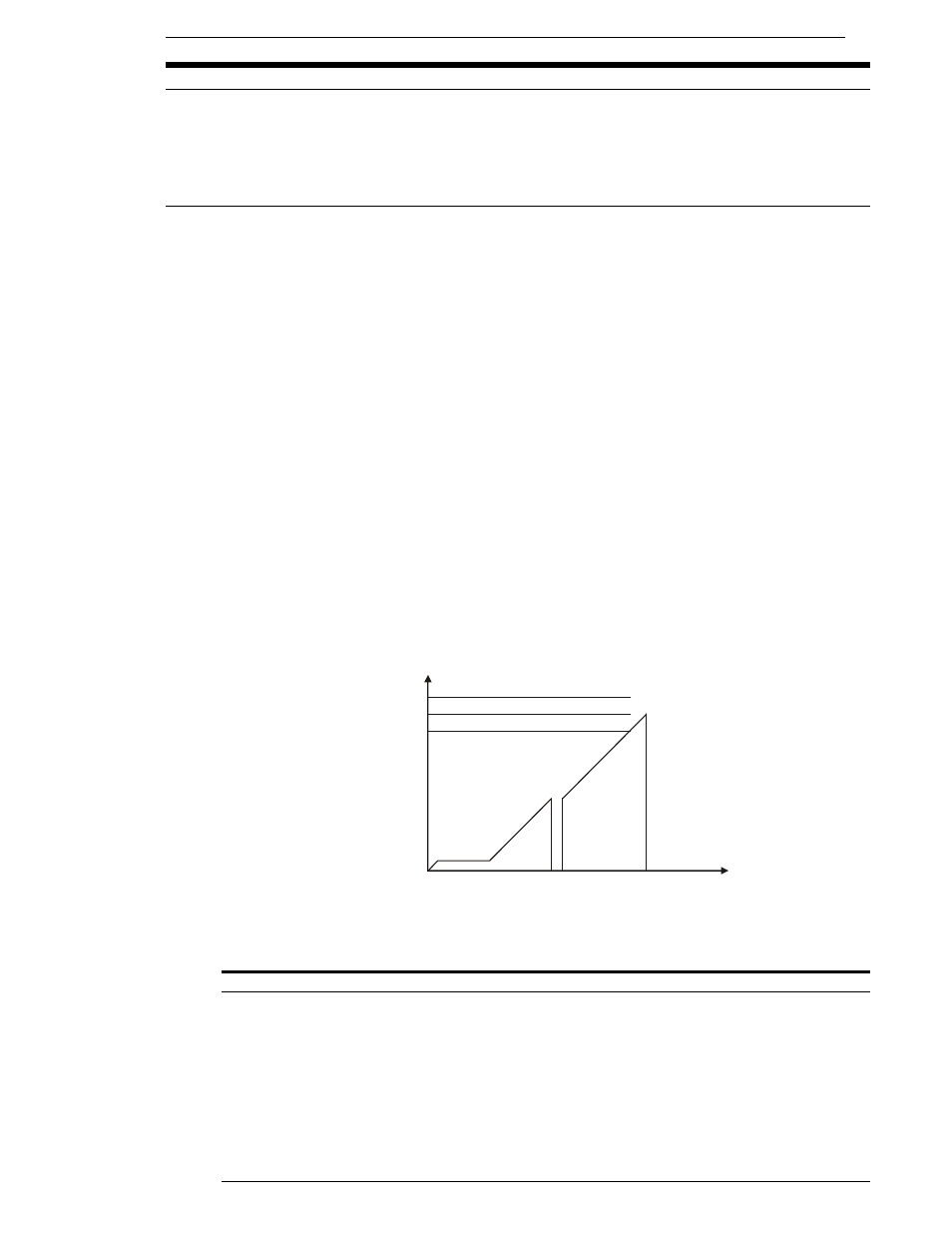

FASTENING CURRENT LIMIT

C

U

R

R

E

N

T

TIME / ANGLE

LOW CURRENT LIMIT

HIGH CURRENT LIMIT

FULL SCALE CURRENT

6.6

Added Functions

Additional functions are available as standard features integrated within the Fusion controller. These

functions may be helpful in special applications or for maintenance reasons. See below for additional

functions.

6.6.1 Current Monitoring / Control

The current monitoring function works as a redundant protection for the torque transducer operations.

By sensing the current drawn by the motor, the system can establish an alternate reference to the

signals generated by the torque transducer preamplifier. It is intended to detect problems with the mo-

tor that would not be detected by the torque transducer and also as a maintenance tool to determine

if there is a problem before the system will shut down.

This function allows the user to set Low Current and High Current Limits. If the current drawn by the

motor overrides the High Current Limit or does not achieve the Low Current Limit, the System acti-

vates the Current Warning PLC Output Signal, without halting the System's operation. This current

warning signal prompts of a potential failure in the system that requires inspection, but allows the sys-

tem to continue until a suitable time is available to inspect the system.

The Fastening current limit allows a limit for maximum current draw during a fastening cycle. If this is

set below Full Scale Current, then the current will not exceed this value during a fastening cycle. This

function is mainly for protecting a motor during Torque recovery applications. If the Fastening Current

Limit is exceeded and the motor stops turning, a Resolver Abnormal fault may occur.

The Full scale current limit is an automatically set reference value. This is generated based upon the

motor/servo used and should not be changed.

Fig. 6-6-1 Current Monitor function