Echelon Series 6000 Chip databook User Manual

Page 162

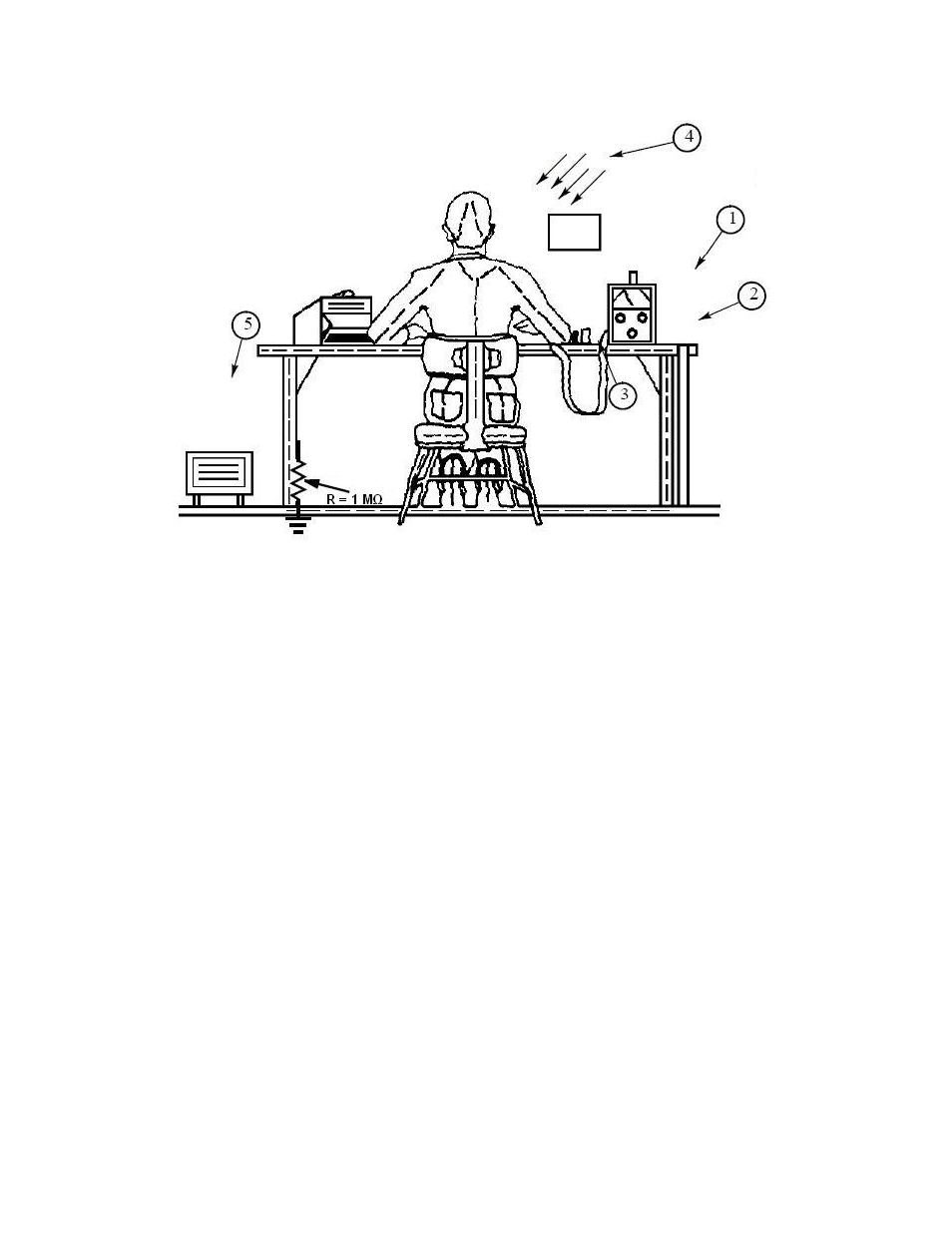

Figure 56. Typical Manufacturing Work Station

Notes for Figure 56:

1. 1/16-inch conductive sheet stock covering bench-top work area.

2. Ground strap.

3. Wrist strap in contact with skin.

4. Static neutralizer (ionized air blower directed at work). Primarily for use in areas

where direct grounding is impractical.

5. Room humidifier. Primarily for use in areas where the relative humidity is less than

45%. Caution: building heating and cooling systems usually dry the air, which

causes the relative humidity inside a building to be less than outside humidity.

The following steps should be observed during board cleaning operation:

1. Vapor degreasers and baskets must be grounded to an Earth ground. Operators

must likewise be grounded.

2. Brush or spray cleaning should not be used.

3. Assemblies should be placed into the vapor degreaser immediately upon removal

from the antistatic container.

4. Cleaned assemblies should be placed in antistatic containers immediately after

removal from the cleaning basket.

5. High-velocity air movement or application of solvents and coatings should be

employed only when module circuits are grounded and a static eliminator is directed

at the module. The use of static-detection meters for line surveillance is highly

recommended.

6. The use of static-detection meters for line surveillance is highly recommended.

150

Handling and Manufacturing Guidelines