2 cyclic communication, Sr-750 series cyclic communication, Cyclic communication setting procedures – KEYENCE SR-750 Series User Manual

Page 95: Cyclic communication, Sr-750 series settings, Plc settings

95

E SR-750 UM

11-2

Cyclic communication

This section describes the SR-750 Series cyclic communication setting procedures

and functions.

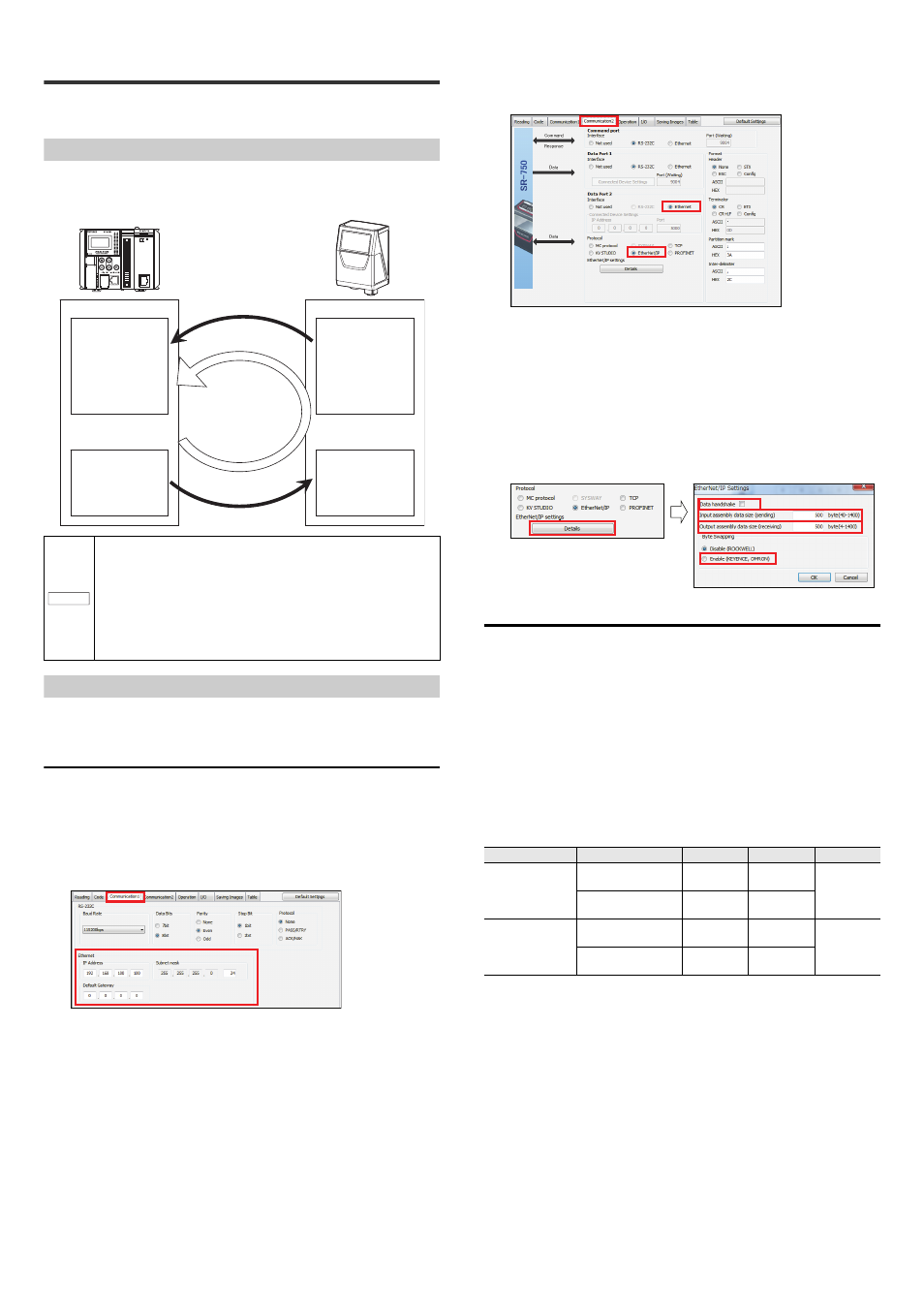

SR-750 Series cyclic communication

When cyclic communication is performed in the SR-750 Series using EtherNet/IP,

SR-750 series functions are assigned to the PLC devices. Use the function

allocated to each device according to the intended usage.

Cyclic communication setting procedures

This section describes the setting procedures when performing cyclic

communication.

SR-750 Series settings

For the SR-750 Series, use the AutoID Network Navigator and perform the

following settings.

1

Communication 1 tab

• IP address setting

• Subnet mask setting

• Default gateway setting

NOTICE

• Communication settings such as cyclic communication's

communication cycle and data size are performed in the PLC.

When there is a large load in the network which connects many

devices including EtherNet/IP devices, delays or packet loss

may occur. Perform a thorough verification before operation.

• When performing EtherNet/IP communication with PLCs (SLC5/

05 MicroLogix Series manufactured by Rockwell, etc.) that do

not support cyclic communication, use message

communication.

Reading result

Handshake information

Device status

Busy/error information

Statistical information

Reading instruction

Handshake instruction

Calibration

Reading result

Handshake information

Device status

Busy/error information

Statistical information

Reading instruction

Handshake instruction

Calibration

IN area

OUT area

OUT area

IN area

Communication cycle (RPI)

Set with PLC

2

Communication 2 tab

• Set the PLC communication interface and protocol.

Interface : Ethernet

Protocol : EtherNet/IP

3

PLC communication's EtherNet/IP settings

Click the EtherNet/IP setting button, open the EtherNet/IP setting screen, and

perform the following settings.

•

: Set "maximum result data size + 44 bytes" or

more.

• Data handshake

: Put a check on this when performing a

handshake process.

• Data area byte swap

: The storage order of data memory (Read

result data/Preset data) can be changed.

Disable: Writes data in an ascending order.

Enable: Writes data in a descending order.

PLC settings

About PLC settings

When performing cyclic communication, perform the following settings in the PLC.

(1) Settings for the connection used

(2) Device settings used in cyclic communication

(For setting procedures, refer to the manual of each PLC.)

* When using the KV Series, making a selection within KV STUDIO will

automatically set (1) and (2).

Connection used

Open a connection from the scanner using EtherNet/IP during cyclic

communication.

There are various types of connections. Usable connections vary depending on the

device.

Connections that the SR-750 Series can use are as follows:

• Exclusive Owner

This connection can perform the following communications.

• PLC

→ SR-750 ............ Control instruction

• SR-750

→ PLC ................. Data Send

Use this connection to send read data of SR-750, and also when PLC performs

control instruction to SR-750 such as start of reading.

Multiple "Exclusive Owner" connections cannot be used for a single unit of SR-

750.

Connection type

Data type

Instance ID

Size (byte)

RPI (ms)

Exclusive Owner

(Data transmission +

control)

Result data

(Input Assemblies)

0X64(100)

40 to 1400

10 to 10000

Control data

(Output Assemblies)

0X65(101)

8 to 1400

Input Only

(Data transmission

only)

Result data

(Input Assemblies)

0X64(100)

40 to 1400

10 to 10000

Control data

(Output Assemblies)

0XFE(254)

0

Input assembly (send)/

Output assembly (receive) size