1 connecting the power source, Power supply to the sr-750 series, Wiring when supplying 24 v to the control cable – KEYENCE SR-750 Series User Manual

Page 6: Connection when supplying power from a poe device, 2 connecting the control cable and wiring, Connecting the power source, Connecting the control cable and wiring, Control cable connection method, Control cable color and the meaning of signal

6

E SR-750 UM

2-1

Connecting the Power

Source

This section describes how to connect the SR-750 Series and the power source.

Power supply to the SR-750 Series

There are 2 methods employed for connecting power source to the SR-750 Series.

• Connect the power supply wire of the control cable to a 24 V DC power supply

device.

• Connect to a PoE (Power over Ethernet) power supply device using the Ethernet

port.

Use only one of the above methods to connect to the power source according to

the usage.

Wiring when supplying 24 V to the control cable

Connection when supplying power from a PoE device

Use the Ethernet cable for the SR-750 Series for connection. Connect the RJ-45

connector of the Ethernet cable to a device (switching hub, etc.) compatible with

the PoE power supply feature.

NOTICE

Make sure to use either one of the connection methods for power

supply.

If power is supplied both from the control cable and PoE power

supply device at the same time, the unit may be damaged.

NOTICE

• Use a steady power supply voltage of 24 V DC ±10%.

• Do not use a power supply other than 24 V DC. Otherwise, it

may cause failure.

• Before connecting or disconnecting cables, make sure to turn

off power to the equipment connected to the SR-750 Series.

Otherwise, it may cause the failure of the SR-750 Series.

NOTICE

Be sure to connect with a PoE power supply device compliant

with IEEE802.3af.

+24 V

+

24 V DC ±10%

Brown

0 V

Blue

SR-750 Series

HUB compatible with PoE power supply

Ethernet cable for the

SR-750 Series

2-2

Connecting the Control

Cable and Wiring

Connect the control cable to the SR-750 Series.

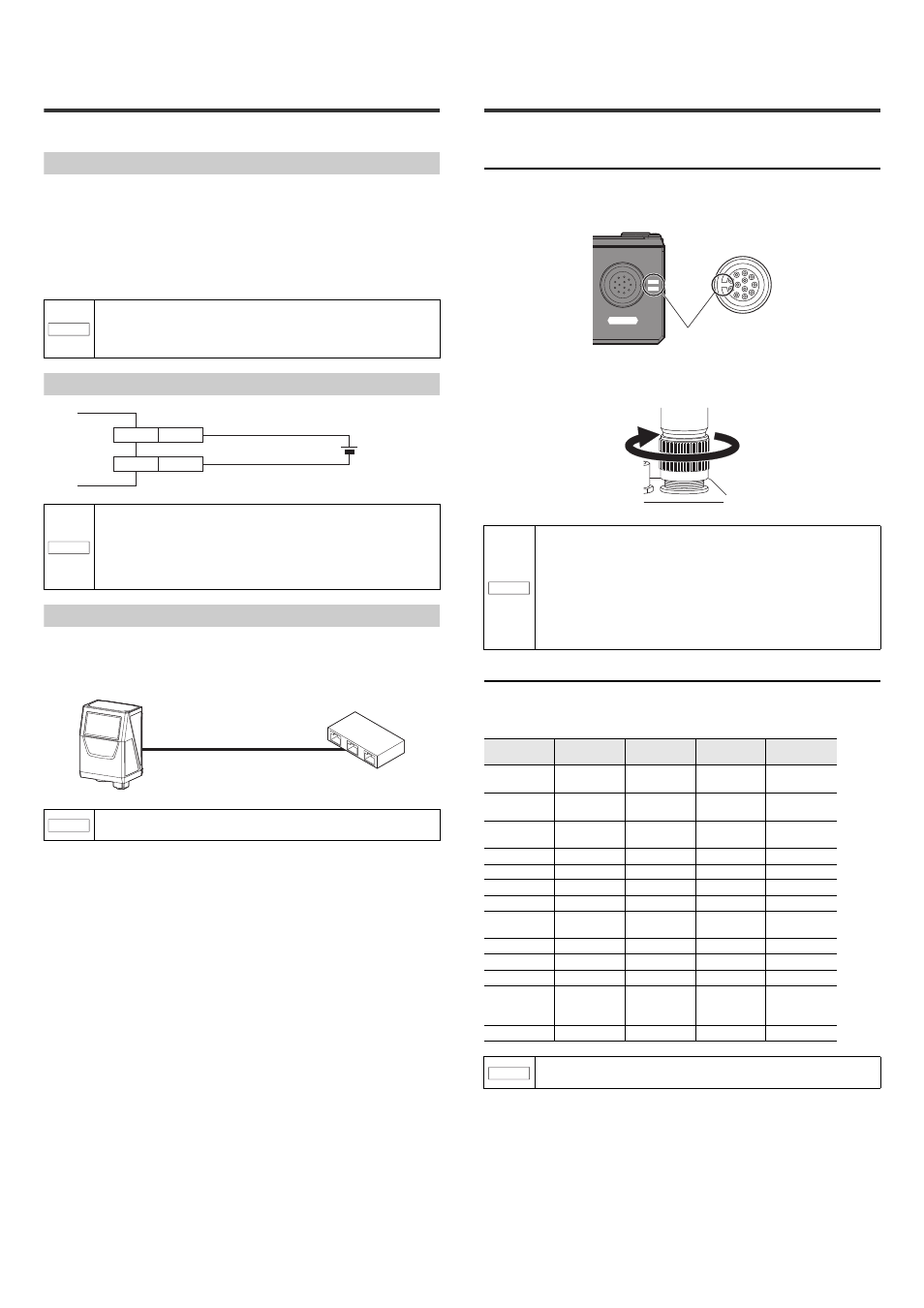

Control cable connection method

1

Align the dent of the cable connector with the marking position next

to the control port.

2

Tighten the connector screw by turning clockwise. Set the screw

tightening torque to 1.5 - 2.0 N•m.

Control cable color and the meaning of signal

The following different color lead wires are drawn out of the control cable. Solder

the lead wire to the connector using the wire attached to the device to be

connected.

NOTICE

When connecting the connector, insert it not to lean toward one

side and securely tighten it. Under-tightening can lead to loose

connector due to vibrations, resulting in poor contact.

Insufficient tightening may not meet the requirements of the

protective structure.

* To get a rough idea, after tightening it by hand, retighten it

approximately 90° - 120° using a tool such as pliers.

Do not repeatedly bend the root of the connector of control cable.

Loose connection may result.

Wire color

Symbol

Description

Signal

direction

AWG size

Brown

24 V

+24 V power

supply

Input

26

Blue

0 V

Power supply

GND

–

26

Orange

RXD

RS-232C

Receive

Input

28

Yellow

TXD

RS-232C Send Output

28

Purple

SGND

RS-232C GND –

28

Green

IN1

IN1 Input

Input

26

Gray

IN2

IN2 Input

Input

28

White and blue INCOM

Input common

mode voltage

–

28

Pink

OUT1

OUT1 Output

Output

28

Aqua blue

OUT2

OUT2 Output

Output

28

White

OUT3

OUT3 Output

Output

28

Black

OUTCOM

Output

common mode

voltage

–

28

Black tube

FG

FG

–

–

NOTICE

Make sure to turn the power off when attaching or removing the

control cable.

POWER

Align the notch with the

marking position.