Wiring – Holtgreven GSE-355 I.S. User Manual

Page 20

11

Wiring

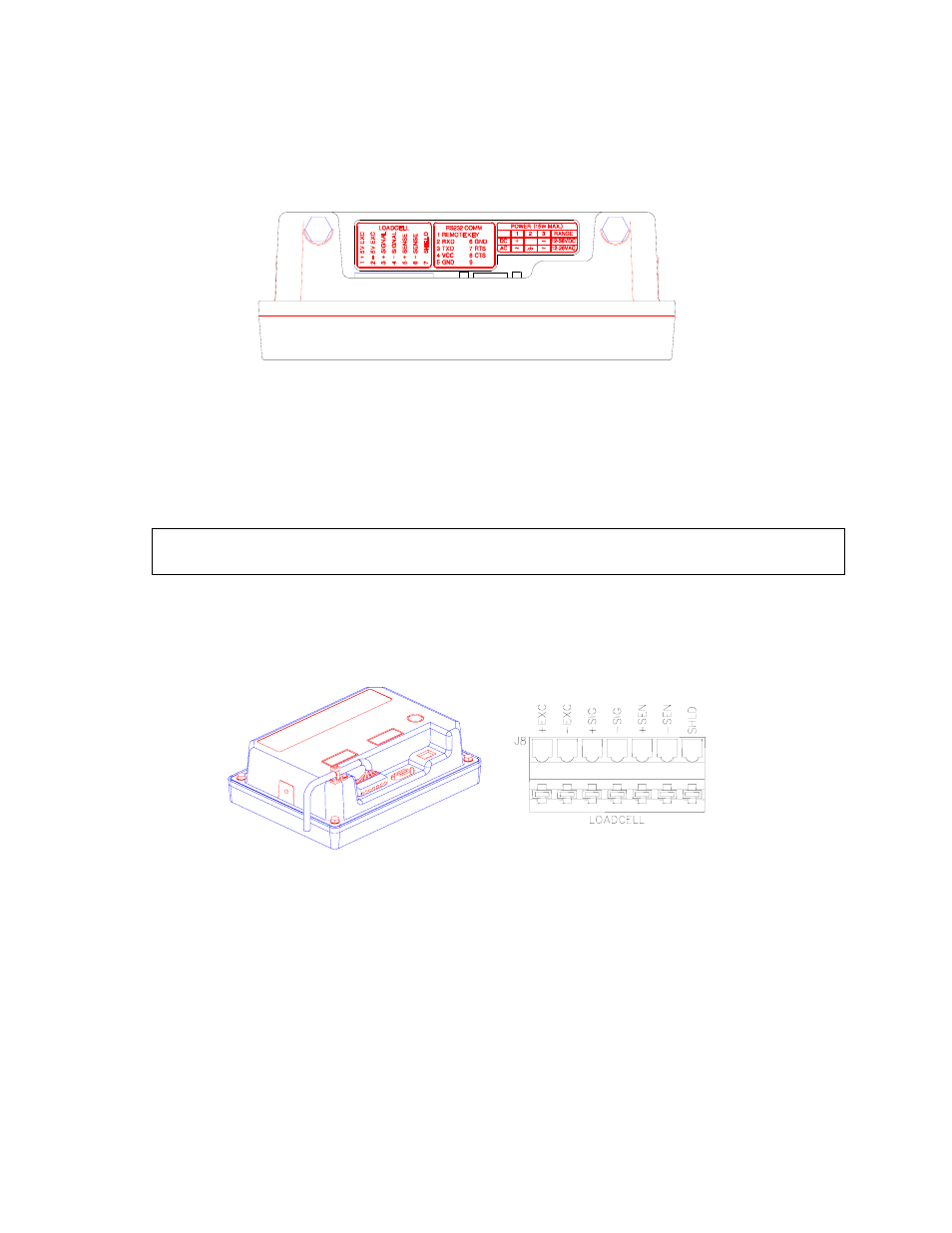

A description of all wiring terminals is included on the bottom label of the zinc die cast enclosure as shown in Figure 9.

L

OAD

C

ELL

C

ONNECTIONS

A high quality braided shield cable with 16 to 24 AWG stranded wire is recommended for load cell or summing box

connections. Secure the cable by the cable tie on the die cast model, or route it through the strain relief supplied on the

back of the internal power supply models (see Figure 10). Either four or six conductor cables can be used.

Do not tin the ends of the load cell wire! A terminal connection free from the effects of vibration and

oxidation can be assured only if the load cell terminals securely grip a bare, stranded wire.

When using four conductor cables, (+ Excitation) must be connected together with (+ Sense), and (- Excitation)

must be connected together with (- Sense) on the Model 350 die cast. Sense jumpers are standard on the Model

350 Stainless Steel (E3 and E4). Utilizing the (+) and (-) Sense leads of six conductor cables provides compensation

for variations in the excitation voltage due to resistance changes in the cable.

Figure 10: Cable Tie on Die Cast & Connector (J8) on Internal Power Supply Models

S

ERIAL

P

ORT

C

ONNECTIONS

Before connecting to the serial port, consideration should be given to the communication protocol and to any remote

key requirements. For information on remote key operation, refer to Remote Key Operation on page 86. Use Table 1:

Serial Port Connections to determine proper wiring to the communication port.

Communication connections are made through the DB9 male connector on the rear of the enclosure or a pigtailed cable

through a strain relief (internal power supply model on J6 comm connection). The cable should be 20 to 28 AWG with

a braided or foil shield for either model type. For maximum noise immunity on the die cast model, use a mating DB9

connector with a metal hood and a braided shield cable. Ensure that the braid makes good connection with the hood.

Figure 9: Model 350 Zinc Die Cast Enclosure Wiring Label