Modbus – IAI America ROBO Cylinder Series User Manual

Page 324

8. Reference Materials

316

Modbus

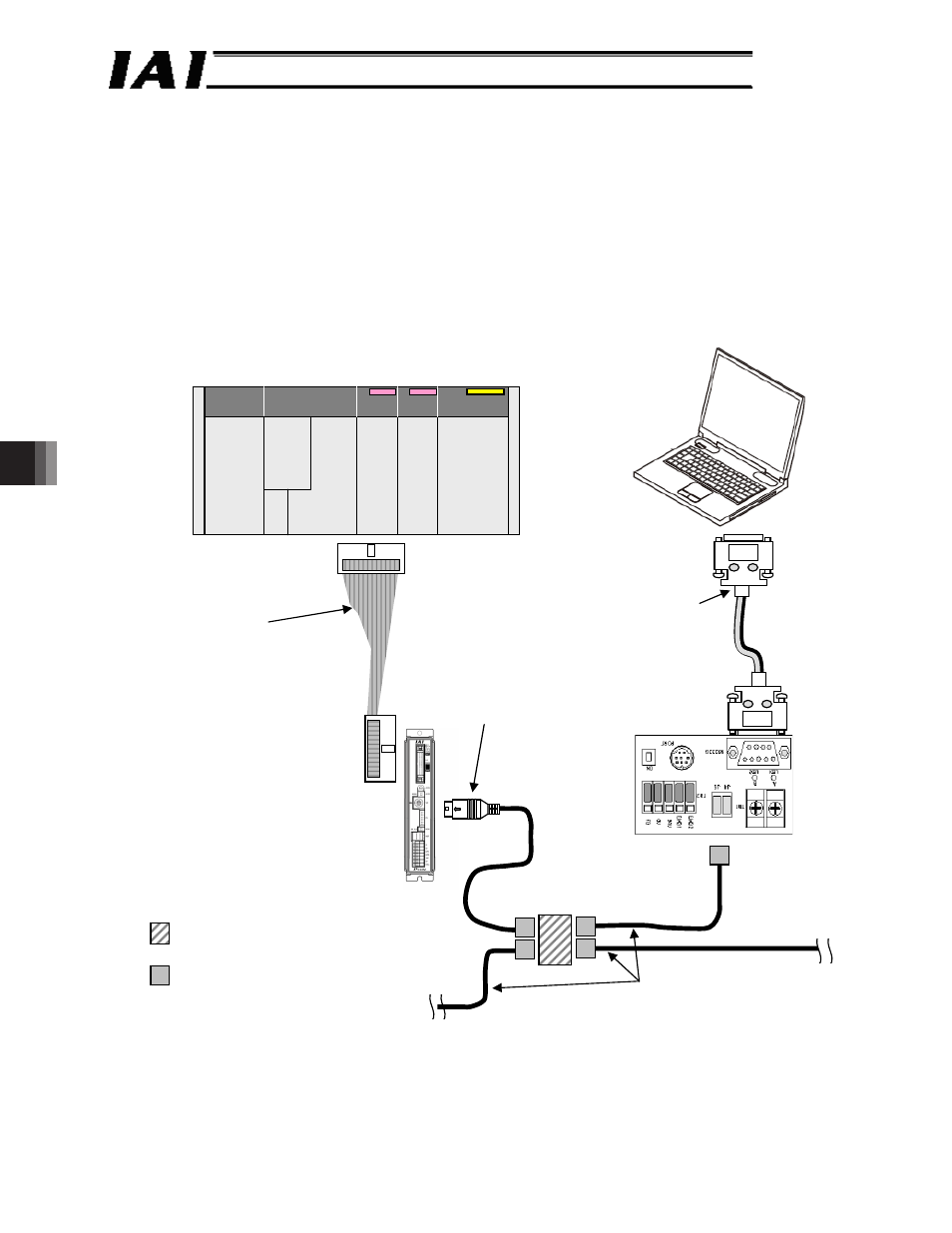

8.2 Configuration of Systems that Use both SIO and PIO

It is possible to monitor the current position and other values via the SIO (communication) by running the

RC controller with PIO. All queries that use function code 03 for either RTU and ASCII can be monitored.

Set PIO/Modbus switching (section 5.4.16 or 6.5.16) to the PIO side and, in case of RC controllers

equipped with a mode switch, set the switch to AUTO. The following RC controller models can use both

PIO and SIO.

x

PCON-C/CG/CF/CA/CAF, PCON-CY, PCON-PL/PO,

x

ACON-C/CG, ACON-CY, ACON-PL/PO,

x

SCON-C/CA,

x

ERC2

Example 1 of system configuration that uses both SIO and PIO

PLC

Fig. 11.1

x

PCON-C/CG/CA/CFA

Positioner I/O cable

(CB-PAC-PI0020)

2 m, comes with the controller

x

PCON-PL/PO

Pulse train I/O cable

(CB-PACPU-PI0020)

2 m, comes with the controller

PC

RS232C cross-connected cable

(prepared by the customer)

(Female)

Controller link cables

CB-RCB-CTL002

(Comes with one junction,

one e-CON connector and

one terminating resistor with

R = 220 : 1/4 W)

Master/

host

SIO converter

Vertical: RCC-TU-SIO-A

Horizontal: RCC-TU-SIO-B

(RS232C RS485)

Junction

(5-1473574-4 made by AMP)

e-CON connector

(*-1473562-4 made by AMP)

Recommended cables: Taiyo Cabletech

(HK-SB/20276xL (m) 2P x AWG22)

Prepared by the customer

PCON-C/CG

(RS232C)

PC