Modbus – IAI America ROBO Cylinder Series User Manual

Page 307

6. Modbus

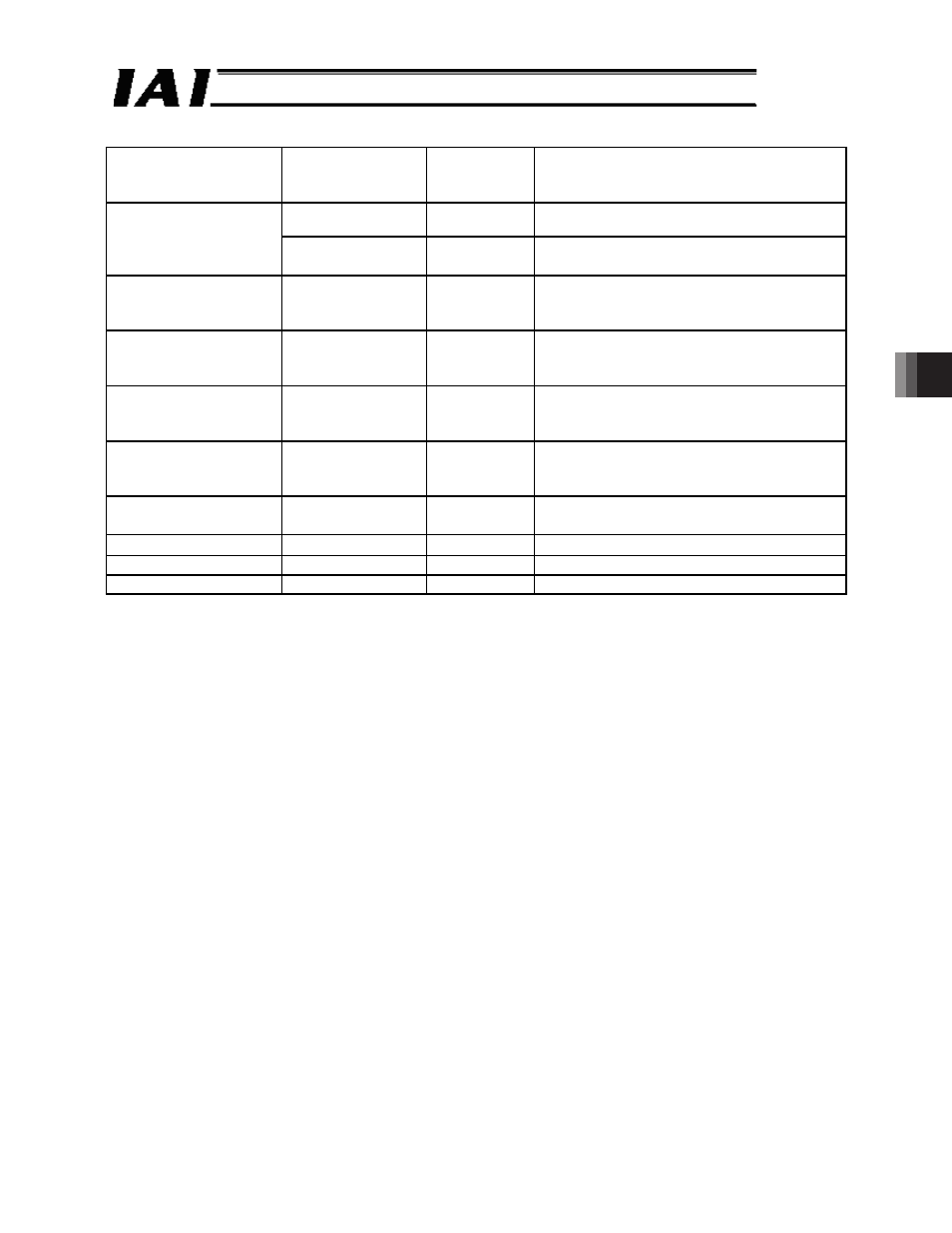

ASCII

299

Modbus

Field

ASCII mode

fixed character

string

Converted

ASCII code

data [H]

Remarks

‘0’, ‘0’, ‘0’, ‘0’

30303030

All upper bits of the 32-bit data are 0.

Changed data 9, 10

(individual zone

boundary -)

Input unit (0.01 mm)

‘0’, ‘F’, ‘A’, ‘0’

30464130

40 (mm) x 100 = 4000 o 0FA0

H

Changed data 11

(acceleration)

Input unit (0.01 G)

‘0’, ‘0’, ‘0’, ‘1’

30303031

0.01 (G) x 100 = 1 o 0001

H

Changed data 12

(deceleration)

Input unit (0.01 G)

‘0’, ‘0’, ‘1’, ‘E’

30303145

0.3 (G) x 100 = 30 o 001E

H

Changed data 13

(push)

Input unit [%]

‘0’, ‘0’, ‘0’, ‘0’

30303030

0 (%) o 0

H

Changed data 14

(threshold)

Input unit [%]

‘0’, ‘0’, ‘0’, ‘0’

30303030

0 (%) o 0

H

Changed data 15

(control flag)

‘0’, ‘0’, ‘0’, ‘0’

30303030

All bits are 0 in the normal operation mode.

0000

b

o

0000

H

Error check

‘E’, ‘E’

4545

LRC check calculation result o EE

H

Trailer

‘CR’, ‘LF’

0D0A

Total number of bytes

79

*1) Calculation of start address

In the example, all data of position No. 12 is changed. Accordingly, the target position address of

position No. 12 is set in the start address field of this query.

1000

H

+ (16 x 12 =192)

H

+ 0

H

= 1000

H

+ C0

H

+ 0

H

= 10C0

H

“10C0” becomes the input value for the start address field of this query.