3 preparation for communication, 1 in case the host uses rs232c interface, Modbus 3 preparation for communication – IAI America ROBO Cylinder Series User Manual

Page 25: Specifications 17, 1) system configuration

3. Specifications

17

Modbus

3 Preparation for Communication

3.1 In Case the Host Uses RS232C Interface

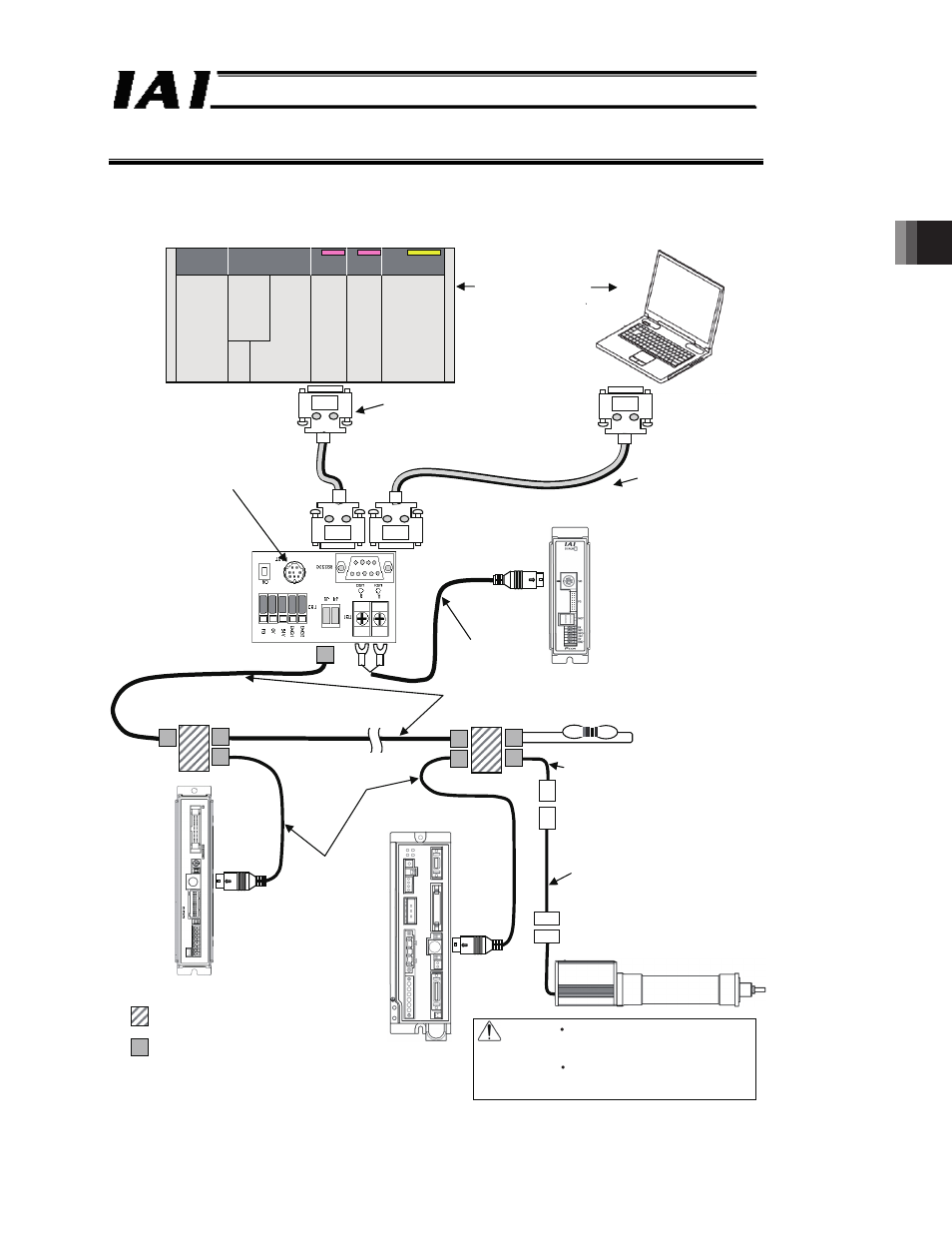

(1) System configuration

The host must be either

a PLC or PC. It is not

allowed to connect both

at the same time.

RS232C cable

(prepared by the customer)

Check the pin assignment of the interface

on the host side and prepare either

straight-through or cross-connected cables

accordingly.

(RS232C)

You can connect IAI’s PC

software or other teaching tool.

Vertical specification:

RCB-TU-SIO-A

Horizontal specification:

RCB-TU-SIO-B

(RS232C RS485)

(Female)

⇔

PCON-*

SCON-*

Junction

(5-1473574-4 made by AMP)

e-CON connector

(*-1473562-4 made by AMP)

Can be connected using a

terminal block, instead.

Controller link cables

CB-RCB-CTL002

(Comes with one

junction, one e-CON

connector and one

terminating resistor

with R = 220Ω, 1/4 W)

Fig. 3.1

RS232C cross-connected cable

(prepared by the customer)

PCON-*

(Female)

Mini DIN, 8-pin connector

Recommended cables

(Taiyo Cabletech

HK-SB/20276xL (m) 2P x AWG22)

Prepared by the customer

Terminating resistor R = 220

When using a commercially available

RS232C ⇔ RS485 converter, adjust

the resistance to the converter.

Cable for network connection

CB-ERC2-CTL001

SIO-compatible power supply I/O cable

CB-ERC2-PWBIO***

Caution

Make sure to use the common 0 V

line of the 24 V power supply for

each controller (other than SCON).

For ROBONET connection, refe r to

the separate ROBONET Operation

Manual.

PC

PLC

Master

/host

ERC2 [Refer to Section 3.2 for connection of ERC3]