Modbus, Example 2) – IAI America ROBO Cylinder Series User Manual

Page 167

5. Modbus RTU

159

Modbus

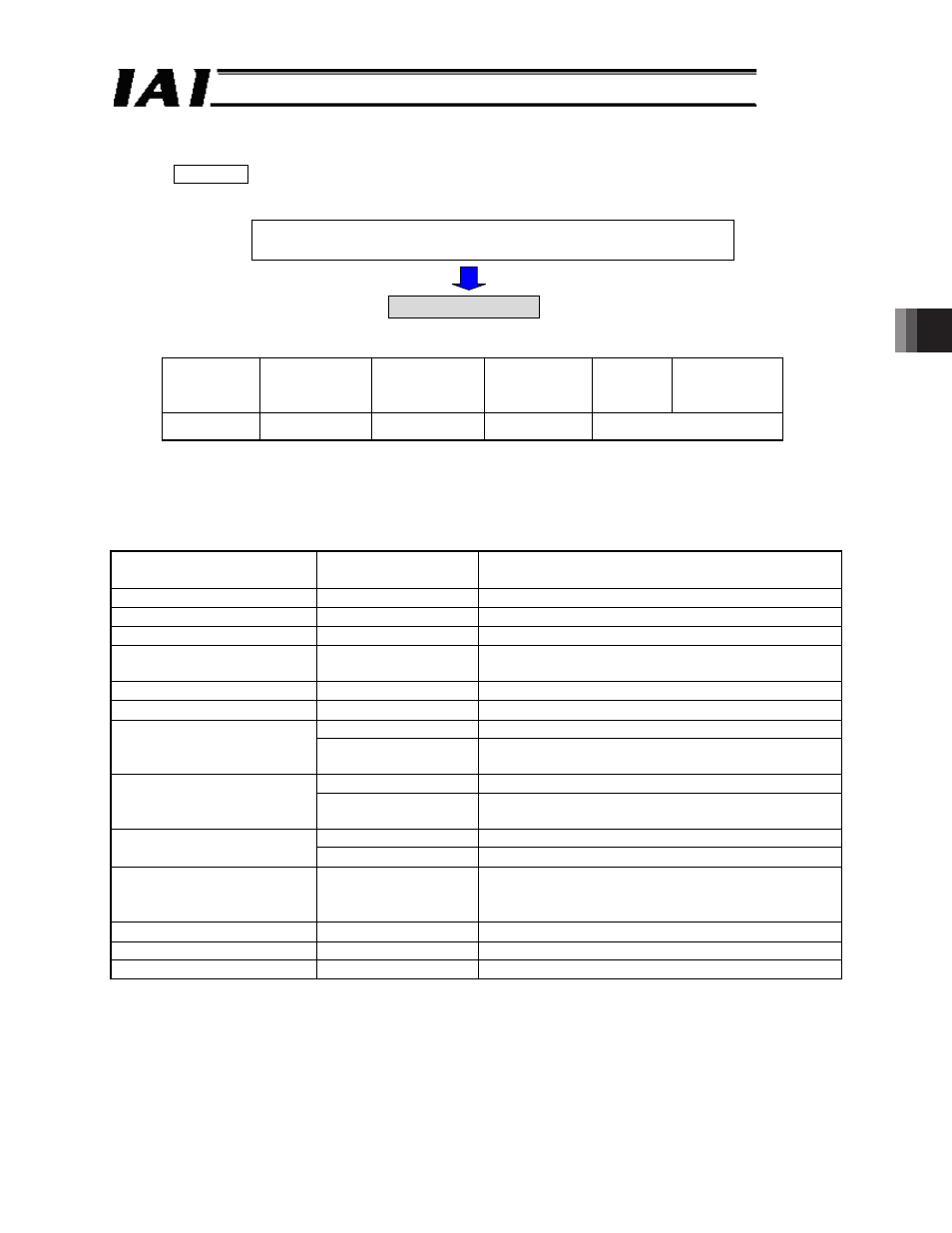

[2] Move by changing the target position. (As well as data other than the target position).

Conditions: Want to move the actuator by changing the target position, speed and

acceleration/deceleration every time.

Write the target position specification register (9900

H

) through

acceleration/deceleration specification register (9906

H

)

(Example2)

Start of movement

(Example 2)

Target position: 50 mm

Target

position

[mm]

Positioning

band

[mm]

Speed

[mm/s]

Acceleration/

deceleration

[G]

Push

[%]

Control flag

50

0.1

100

0.3

Need not be set.

ᴾ

Query : 01 10 9900 0007 0E 0000 1388 0000 000A 0000 2710 001E 50CFᴾ

ᴾ

Response : 01 10 9900 0007 AF57

--- The query message is copied, except for the number of bytes and new data, and returned

as a response.

ᴾ

ᴾ

Breakdown of Query Message

Field

RTU mode

8-bit data

Remarks

Start

None

Silent interval

Slave address

01

H

Axis number + 1

Function code

10

H

Start address

9900

H

The starting address corresponds to the setting of

target position specification register 9900

H

.

Number of registers

0007

H

Addresses 9900

H

to 9906

H

are written.

Number of bytes

0E

H

7 (registers) × 2 = 14 (bytes) o E

H

0000

H

All upper bits of the 32-bit data are 0.

New data 1, 2

(target position)

Input unit (0.01 mm)

1388

H

50 [mm] × 100 = 5000 o 1388

H

0000

H

All upper bits of the 32-bit data are 0.

New data 3, 4

(Positioning band)

Input unit (0.01 mm)

000A

H

0.1 [mm] × 100 = 10 o 000A

H

0000

H

All upper bits of the 32-bit data are 0.

New data 5, 6 (Speed)

Input unit (0.01 mm/sec)

2710

H

100 [mm/s] ×100 = 10000 o 2710

H

New data 7

(Acceleration/deceleration)

Input unit (0.01 G)

001E

H

0.3 [G] × 100 = 30 o 001E

H

Error check

50CF

H

CRC checksum calculation result o 50CF

H

End

None

Silent interval

Total number of bytes

23