Modbus – IAI America ROBO Cylinder Series User Manual

Page 274

6. Modbus

ASCII

266

Modbus

6.5.15 Load Cell Calibration Command <

connected.

(1) Function --- SCON-CA only

The dedicated load cell is calibrated.

The factory setting of your load cell is that the ON status corresponds to a no-load state. If you want

to define the reference state as a condition where a work part (load) is installed, calibrate the load

cell.

Also calibrate the load cell in other situations as necessary (readjustment, inspection, etc.).

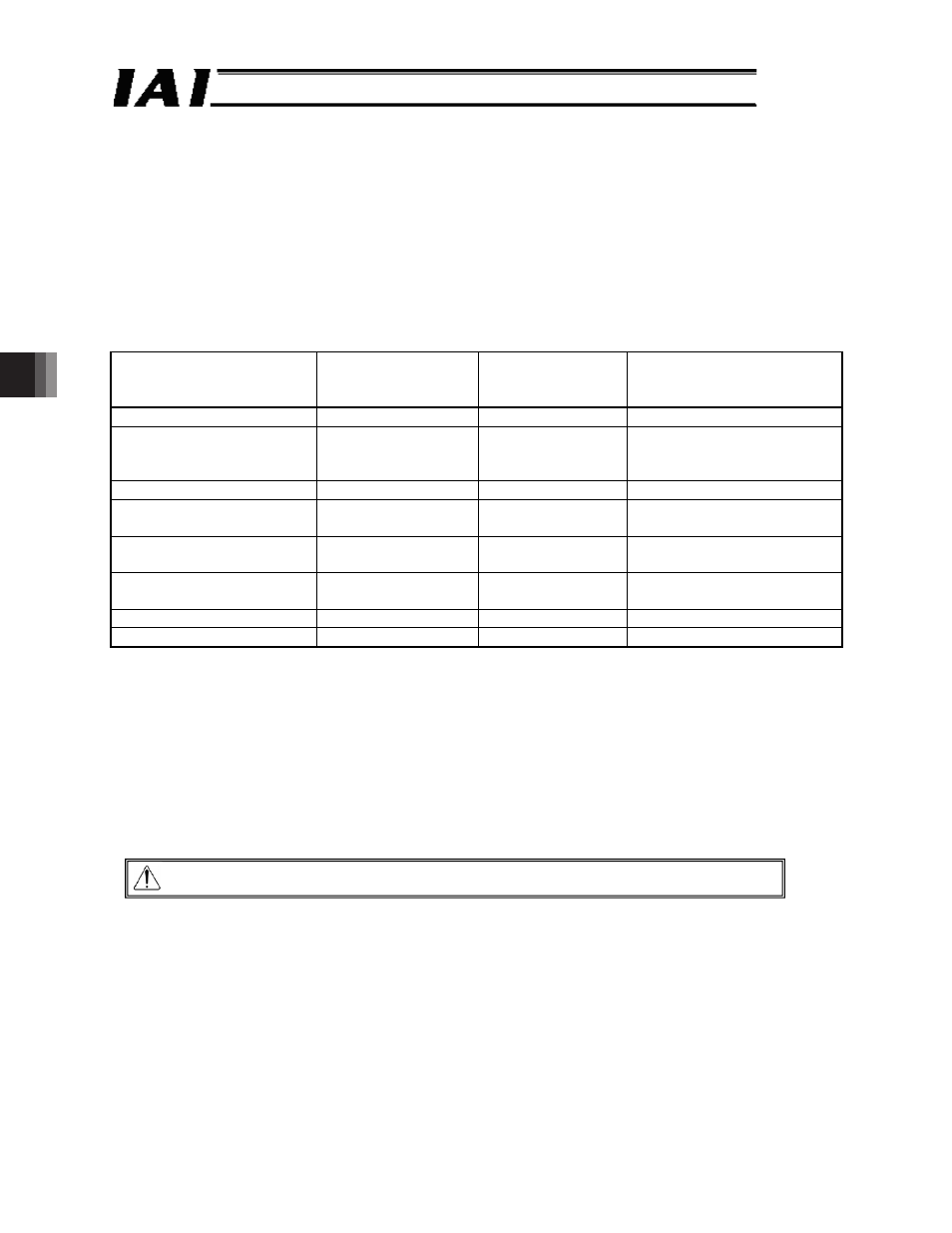

(2) Query format

Field

Number of characters

ASCII mode

character string

(fixed)

Remarks

Header

1

‘:’

Slave address [H]

2

Arbitrary

Axis number + 1 (01

H

to 10

H

)

00

H

when broadcast is

specified

Function code [H]

2

‘0’, ‘5’

Write to a single coil DO

Start address [H]

2

‘0’, ‘4’ ‘2’, ‘6’

Load cell calibration

command

Changed data [H]

2

Arbitrary

Calibration command: FF00

H

Normal operation: 0000

H

Error check [H]

2

LRC calculation

result

Trailer

2

‘CR’, ‘LF’

Total number of bytes

17

(3) Calibration procedure

[1] Stop the actuator operation. (The load cell cannot be calibrated while the actuator is

performing any axis operation or push-motion operation or being paused, in which case 0E1

(load cell calibration error) alarm generates.)

[2] Turn this signal ON and keep it ON for at least 20 ms.

[3] When the calibration is complete, the calibration complete signal (CEND of device status

register 1 explained in 4.3.2 (12)) turns ON. After confirming that the CEND has turned ON,

turn OFF the CLBR.

If the calibration was unsuccessful, a 0E1 (load cell calibration error) alarm generates.

Caution: Normal operation commands are not accepted while the CLBR is ON.