Modbus – IAI America ROBO Cylinder Series User Manual

Page 299

6. Modbus

ASCII

291

Modbus

(Example 6)

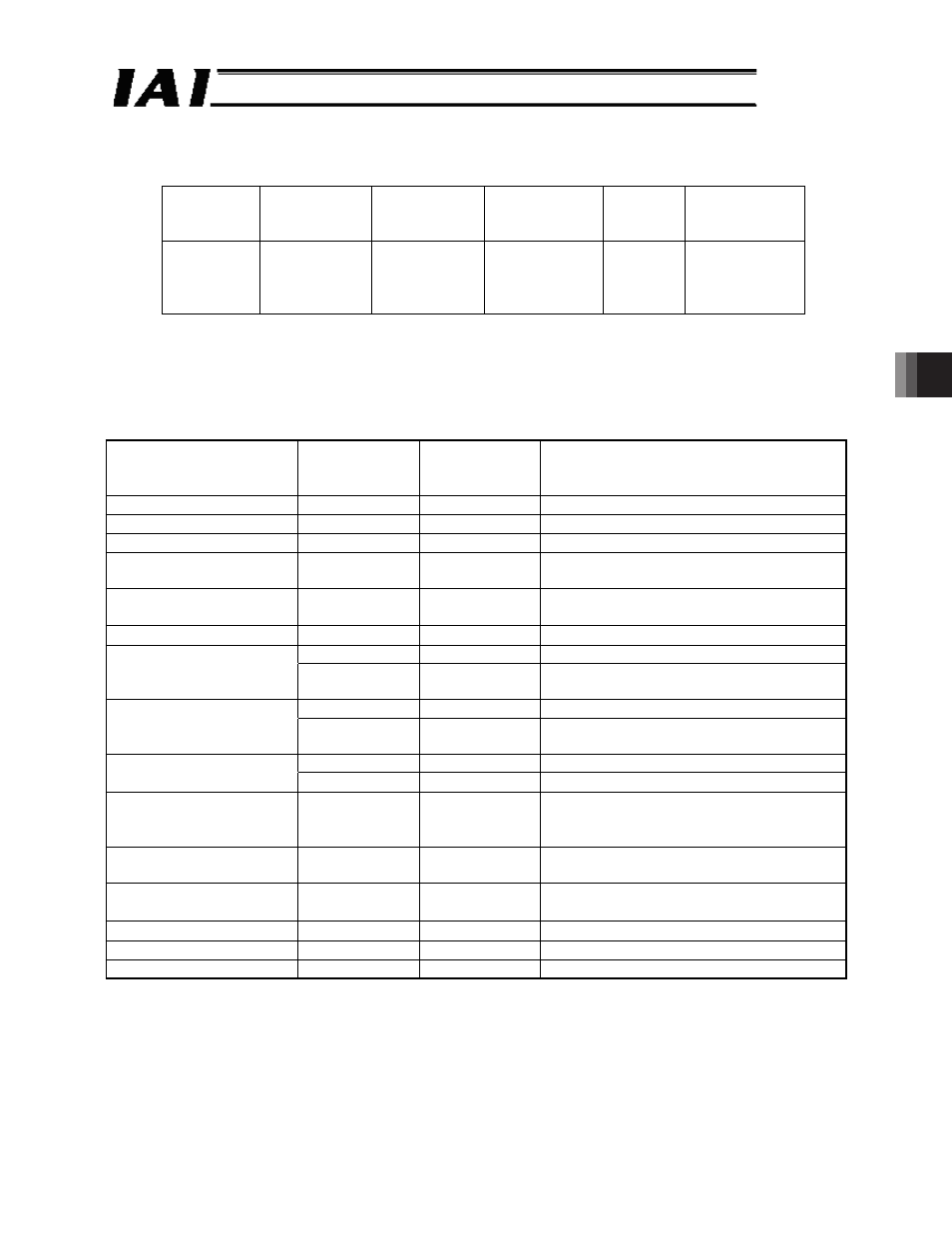

Perform a push-motion operation for 20 mm from the 50-mm position at a

current-limiting value of 70%.

Target

position

[mm]

Positioning

band

[mm]

Speed

[mm/s]

Acceleration/

deceleration

[G]

Push

[%]

Control flag

50

20

100

0.3

70

Push-motion

operation

(bit1 = 1,

bit2 = 0, 1)

Query: 01 10 9900 0009 12 0000 1388 0000 07D0 0000 2710 001E 00B2 0006 BC[CR][LF]

Response: 01 10 9900 0009 4D[CR][LF]

--- The query message is copied, except for the number of bytes and new data, and returned

as a response.

ᴾ

Breakdown of Query Message

Field

ASCII mode

fixed character

string

Converted

ASCII code

data [H]

Remarks

Header

‘:’

3A

Slave address

‘0’, ‘1’

3031

Axis No. 0 + 1

Function code

‘1’, ‘0’

3130

Start address

‘9’, ‘9’, ‘0’, ‘0’

39393030

The start address is the target position

specification register 9900

H

.

Number of registers

‘0’, ‘0’, ‘0’, ‘9’

30303039

Specify 9900

H

through 9908

H

as the

addresses to be written.

Number of bytes

‘1’, ‘2’

3132

9 (registers) x 2 = 18 (bytes) o 12

H

‘0’, ‘0’, ‘0’, ‘0’

30303030

All upper bits of the 32-bit data are 0.

New data 1, 2

(target position)

Input unit (0.01 mm)

‘1’, ‘3’, ‘8’, ‘8’

31333838

50 [mm] × 100 = 5000 o 1388

‘0’, ‘0’, ‘0’, ‘0’

30303030

All upper bits of the 32-bit data are 0.

New data 3, 4

(positioning band)

Input unit (0.01 mm)

‘0’, ‘7’, ‘D’, ‘0’

30374430

20 [mm] × 100 = 2000 o 07D0

H

‘0’, ‘0’, ‘0’, ‘0’

30303030

All upper bits of the 32-bit data are 0.

New data 5, 6 (speed)

Input unit (0.01 mm/sec)

‘2’, ‘7’, ‘1’, ‘0’

32373130

100 [mm/s] × 100 = 10000 o 2710

H

New data 7

(acceleration/deceleration)

Input unit (0.01 G)

‘0’, ‘0’, ‘1’, ‘E’

30303145

0.3 [G] × 100 = 30 o 001E

H

New data 8 (push)

Input unit (%)

‘0’, ‘0’, ‘B’, ‘2’

30304232

70 [%] o B2

H

New data 9 (control flag)

‘0’, ‘0’, ‘0’, ‘6’

30303036

(Push setting)

1000b o 0006

H

Error check

‘B’, ‘C’

4243

LRC check calculation result o BC

H

Trailer

‘CR’, ‘LF’

0D0A

Total number of bytes

55