Parameters, Details of each input signal – IAI America ASEL User Manual

Page 322

Part 3 Positioner Mode

Chapter 2 Standard Mode

300

Part 3 Positioner Mode

2. Parameters

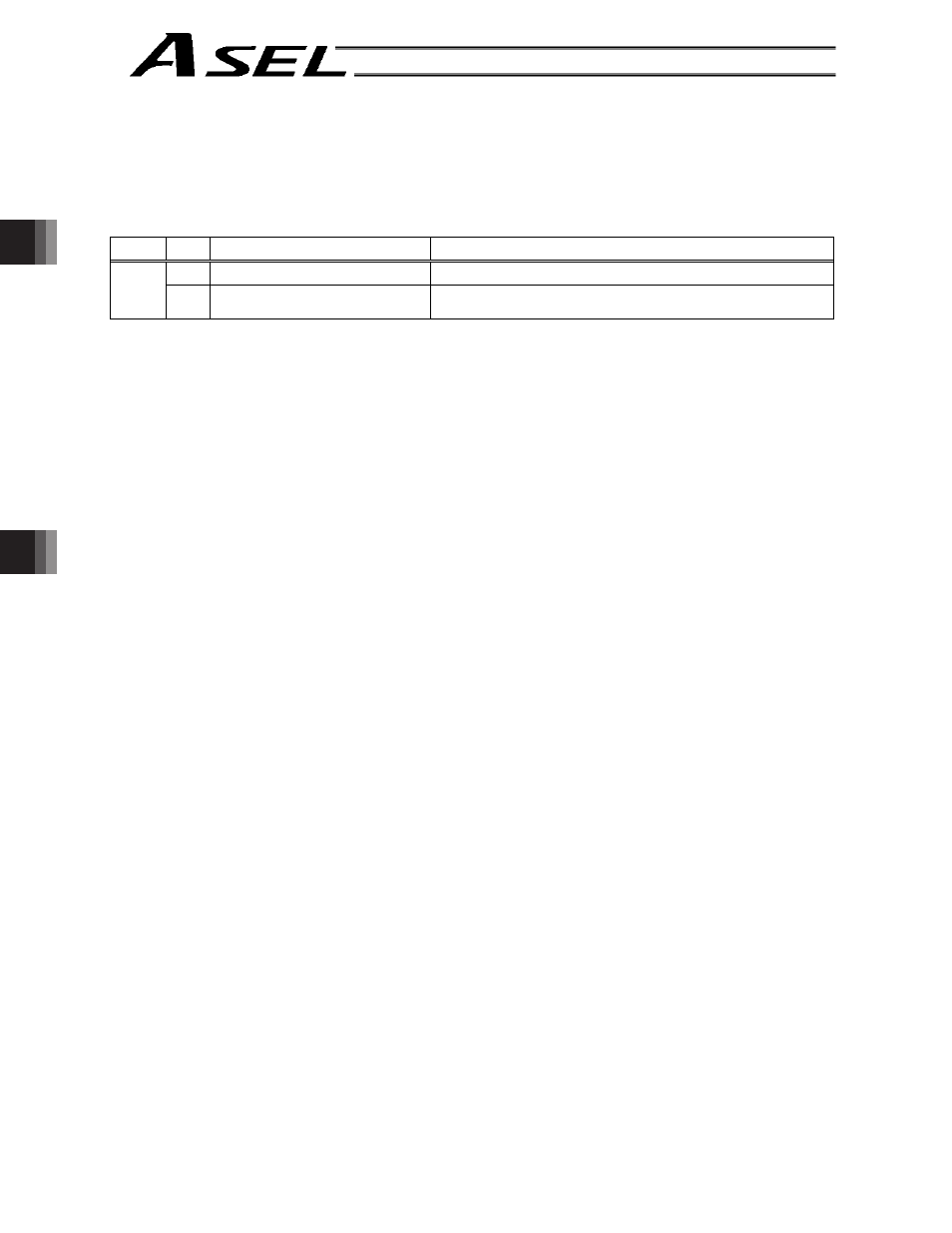

To use the controller in the standard mode, set other parameter No. 25 to “1.”

Position numbers are specified as binary codes according to the factory setting. To change the input mode

to BCD, set a value “other than 0” in other parameter No. 25.

No.

Parameter

Function

25 Operation mode type

1: Standard mode

Other

71 Positioner mode parameter 1

Position-number input mode specification (0: Binary, z 0: BCD)

* Default value: 0 (Binary)

3. Details of Each Input Signal

Start (CSTR)

When the OFF o ON leading edge of this signal is detected, the controller will load the target point

number specified by the 13-bit binary code consisting of PC1 through PC13, and perform positioning to

the target position specified by the corresponding position data.

Before movement is started, the target position, speed and other operation data must be set in the

position table using a PC or teaching pendant.

If this signal is input when no single home-return operation has been performed after the power was input

(= when the HEND output signal is OFF), “C6F, Home-return incomplete error” will generate.

Command position number (PC1 through PC13)

When a movement command is executed upon the OFF o ON edge of the start signal, the controller will

load the command position number specified by the 13-bit binary code consisting of signals PC1 through

PC13.

The weight of each bit is as follows: 2

0

for PC1, 2

1

for PC2, 2

2

for PC3, 2

3

for PC4, 2

4

for PC5, ..., and 2

10

for PC11. By combining these bits, any position number between 0 and 1500 (maximum) can be specified.

The input mode can be changed to BCD by changing the setting of other parameter No. 71, as follows:

Other parameter No. 71 = 1 (BCD input)

(Default setting of other parameter No. 71 = 0 (Binary input))

In the BCD input mode, PC1 through 4 indicate the one’s place, PC5 through 8 indicate ten’s place, PC9

through 12 indicate the hundred’s place, and PC13 indicates the thousand’s place.

Pause (*STP)

If this signal turns OFF while the actuator is moving, the controller will cause the actuator to decelerate to

a stop.

The remaining travel distance will be held, which means that when the signal turns ON again, the actuator

will resume movement of the remaining travel distance.

To cancel the movement command altogether after turning OFF the pause signal, turn OFF the

cancellation signal while this signal is OFF to cancel the remaining travel distance.

The pause signal can be used for the following purposes:

[1] As a sensor to detect entry into a specified area around the system or for other lower-level safety

measures to stop the axis while the servo is on

[2] To prevent contact with other equipment

[3] For positioning based on sensor or LS signal detection

(Note) When this signal is input during home return, the movement command will be held if the actuator

has not yet contacted the mechanical end. If the signal is input after the actuator has reversed

upon contacting the mechanical end, home return will be performed again.