Programming, Operation manual – ACU-RITE MILLPWR 3 Axes User Manual

Page 49

PROGRAMMING

MILLPWR

®

Operation Manual

3-13

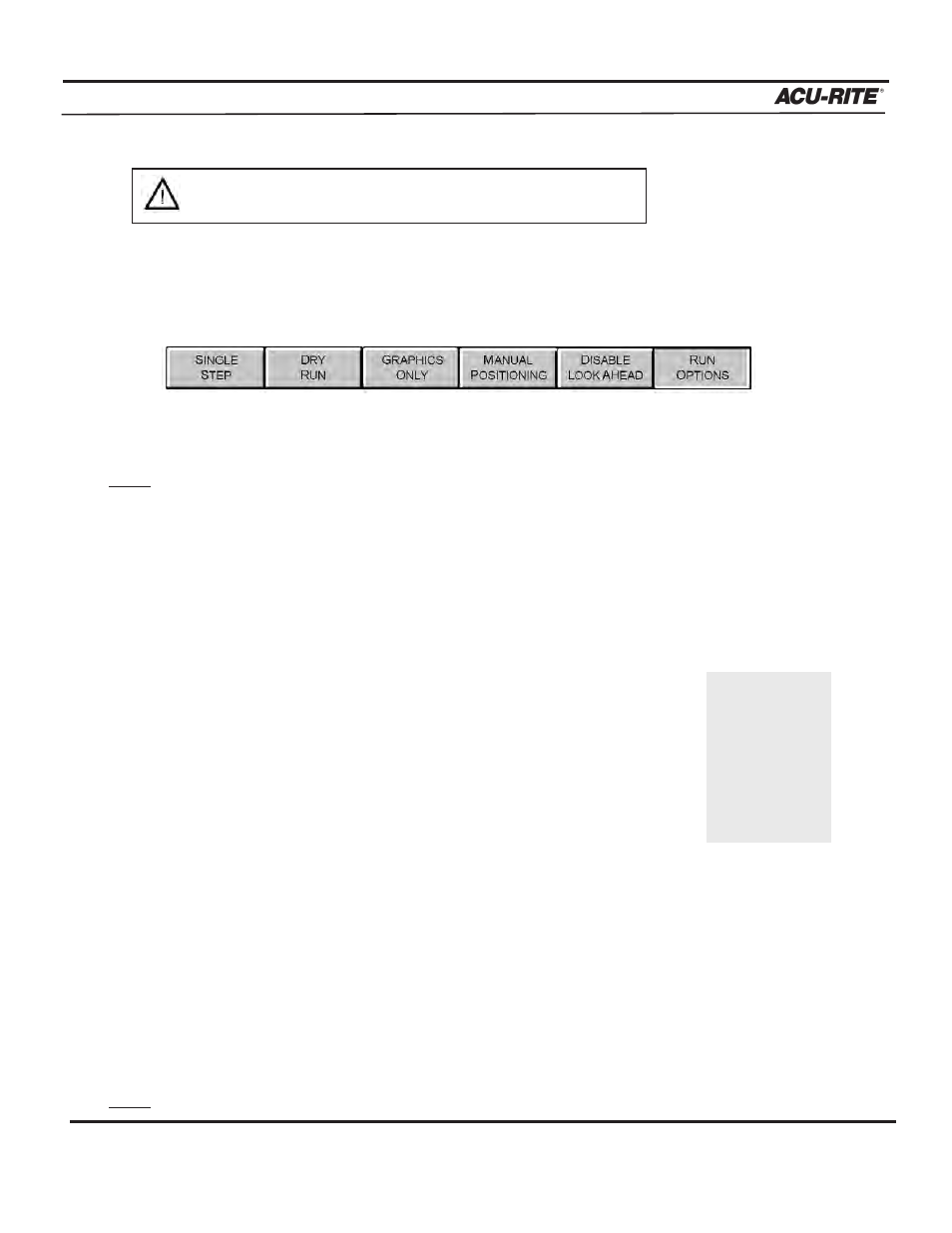

Before you machine a part, it is always a good idea for you to test your program for things like the

correct tool path, count direction, feed rate, and sequence of operations.

MILLPWR

provides several

run-time options to assist you. From the PGM screen, press

RUN OPTIONS

to display the following

softkeys:

Press any softkey to activate the option; press it again to deactivate it.

Note:

Before you press the

GO

key to begin the “Single Step,” “Dry Run” or “Manual Positioning”

features, check that the tool will not touch the workpiece when the quill begins to move. To

avoid interference, we suggest that you do one or more of the following:

•

Lower the knee

•

Remove the tool or workpiece

•

Reestablish datum away from the part (refer to Establishing Datum)

SINGLE STEP

Normally, a continuous contour will be machined without stopping. With

“Single Step” activated,

MILLPWR

will stop after each step. This enables

you to check the position of the Z-axis relative to your part and ensure that

the tool path and other program details are correct. Press the

GO

key to

begin.

DRY RUN

With “Dry Run” activated,

MILLPWR

will run your entire program at high

speed without stopping. You can visually follow the position of the tool relative to your part and

ensure that the tool path and other program details are correct. The dry run speed is defined in

Setup. Press the

GO

key to begin.

GRAPHICS ONLY

With this activated, the table and quill will not move. The graphics screen will show you how your

part will be cut. You can see all the normal feed rates, tool changes and so on. Press the

GO

key to

begin.

Note: Dry Run and Graphics Only can be used to quickly verify your program.

To test your

program quick-

ly, press both

the DRY RUN

and GRAPHICS

ONLY softkeys.

Whenever you are about to run a program, check that the

handles are recessed.

Testing Your MILLPWR Program