Introduction, Operation manual – ACU-RITE MILLPWR 3 Axes User Manual

Page 22

INTRODUCTION

MILLPWR

®

Operation Manual

1-12

Setting Z-axis Datum when Changing Tools

Whenever you encounter a

SET TOOL

step,

MILLPWR

will display the DRO screen and let you know

which tool to load. If no tool diameter was programmed in the “Tool Step,” you will be prompted to

provide one.

•

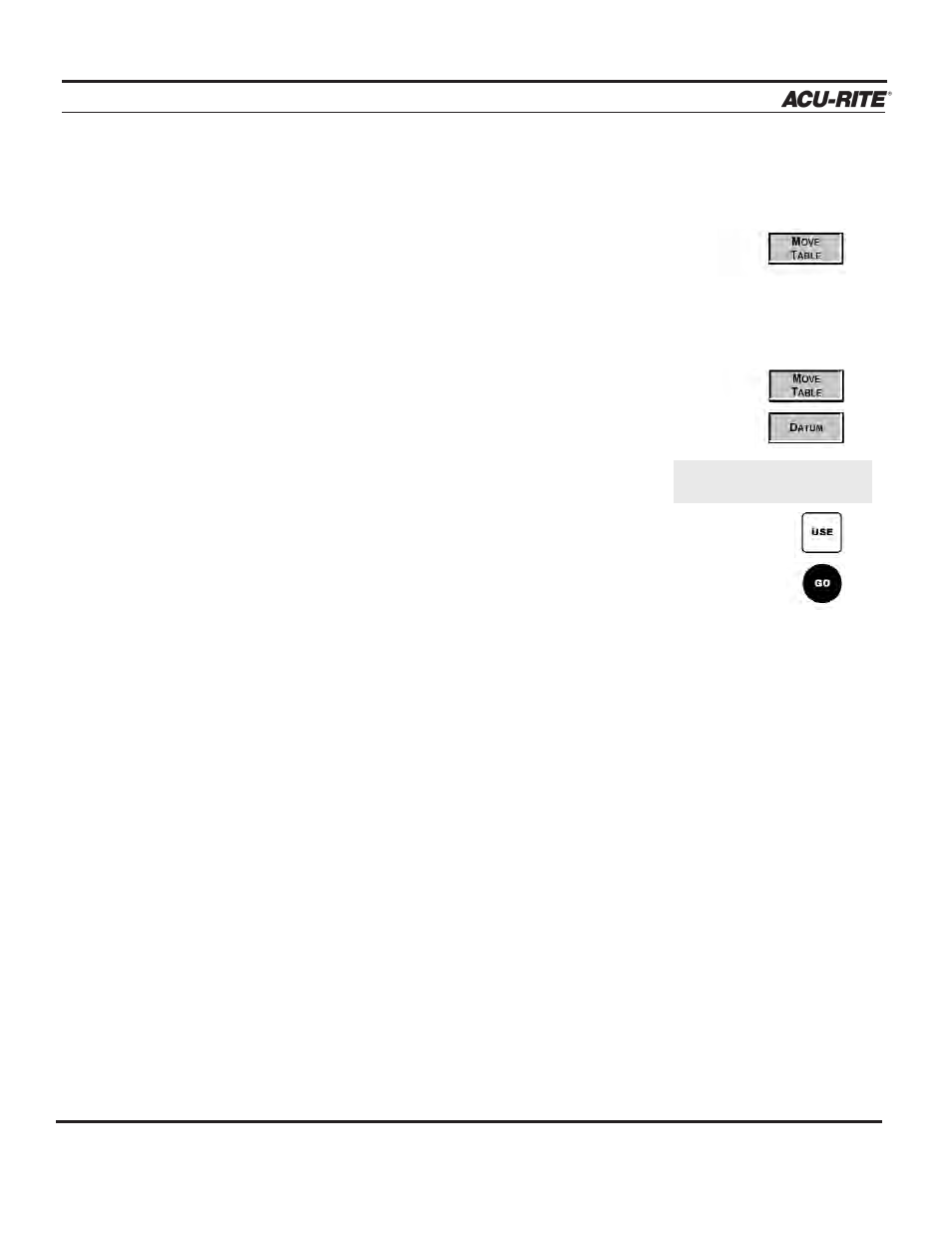

Use the

MOVE TABLE

softkey and arrow keys to

move the tool away from your workpiece.

•

Press the move table softkey again to turn off the motors.

•

Insert the required tool into the spindle.

•

Using the

MOVE TABLE

feature, position the tool over

the surface of a known depth on your workpiece.

•

Press the

DATUM

softkey.

•

Position your tool so that it touches a known surface,

then enter that position into the Z-axis datum.

•

Press the

USE

key.

•

Raise the tool and press the

GO

key to continue the

program.

Drilling Conventions

Peck

“Hole” and “Position/Drill” steps give you the option of programming the quill to

“peck” or pause briefly. Peck cycles are used to break chips and reduce chip buildup

during drilling operations.

You can control how frequently a peck occurs by entering a value in the “Peck” field.

Tool Retract

Using the “Tool Retract” feature, you can program

MILLPWR

to raise the quill at a speci-

fied distance or frequency. This will allow the tool you’re drilling with to cool.

Dwell

“Dwell” is the length of time (in seconds) that the quill will pause during a tool retract.

If the surface is at datum 0,

use the Z = 0 softkey.