Setup, Operation manual – ACU-RITE MILLPWR 3 Axes User Manual

Page 198

SETUP

MILLPWR

®

Operation Manual

7-18

Error Compensation

MILLPWR

is able to automatically calculate and compensate for machine

tool wear.

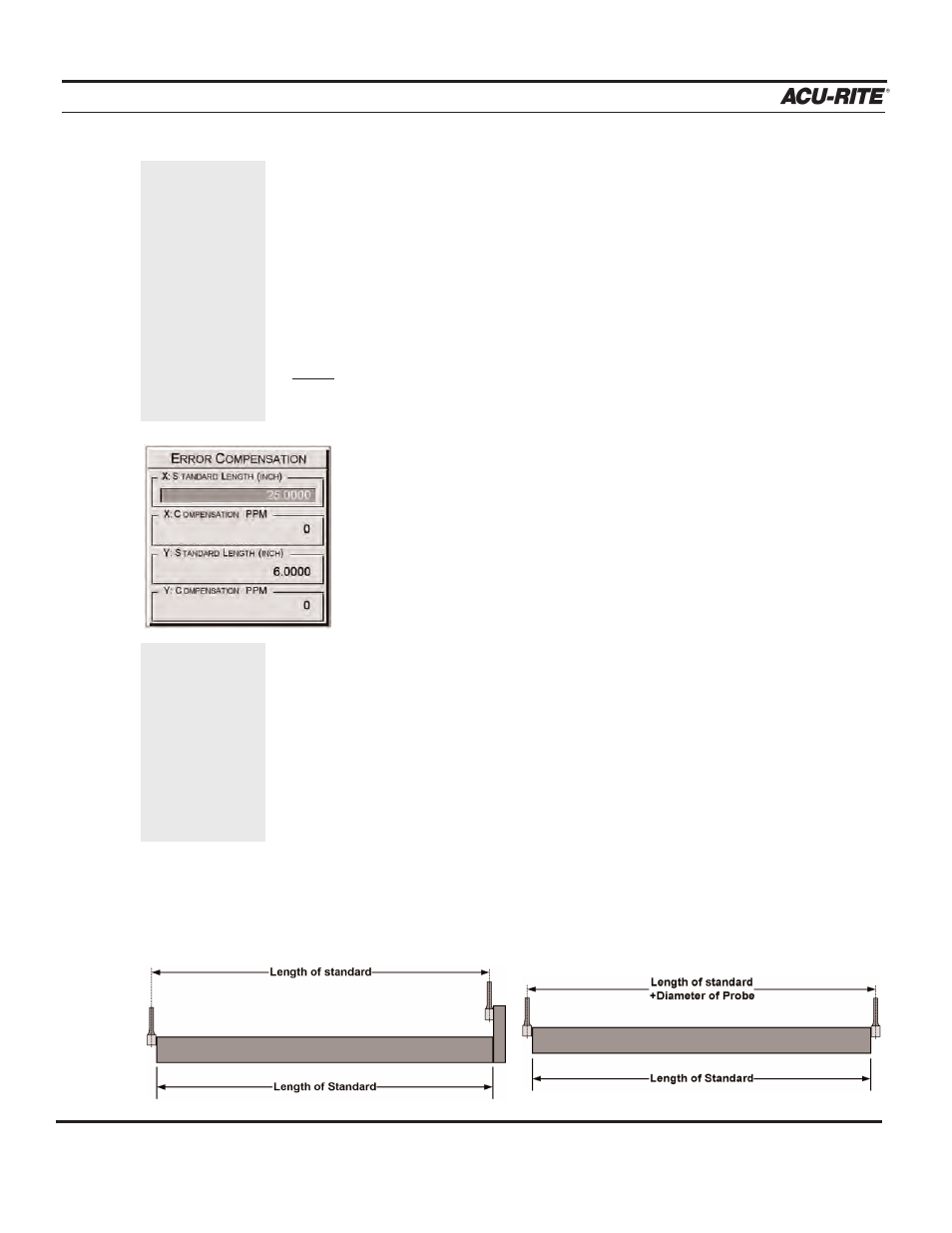

If you know the error compensation value in parts per million (PPM), you

can enter it directly. Otherwise, use the following procedure to determine

the value for each axis:

Note: You can only perform error compensation for one axis at a time.

• Set up a standard of known length (e.g., a gage block), by indicat-

ing it in along the axis to be measured. Check that the standard is

straight and parallel with the axis you’re working with.

• Enter the length of the standard.

If you need to touch each end of the standard using opposite

edges of the electronic edge finder or mechanical indicator, be

sure to include its diameter when entering the length of the

standard. (Refer to the graphic below.)

• Touch one end of the standard and press the

FIRST POINT

softkey.

If you’re using an electronic edge finder, you won’t have to

press the first point softkey.

• Touch the opposite end of the standard and press the

SECOND

POINT

softkey. If you’re using an electronic edge finder, you

won’t have to press the second point softkey.

MILLPWR

will determine and automatically enter the correct com-

pensation factor in parts per million.

• Continue with Setup or press the

USE NEW SETTINGS

softkey.

Before perform-

ing linear error

compensation,

you need to

ensure that

your machine is

properly adjust-

ed. Refer to the

manufacturers’

instructions for

proper adjust-

ment proce-

dures.

Check between

the first and

second points

several times—

note the error

value to ensure

repeatability.