Elecraft K2 Owner's Manual User Manual

Page 77

76

E

LECRAFT

®

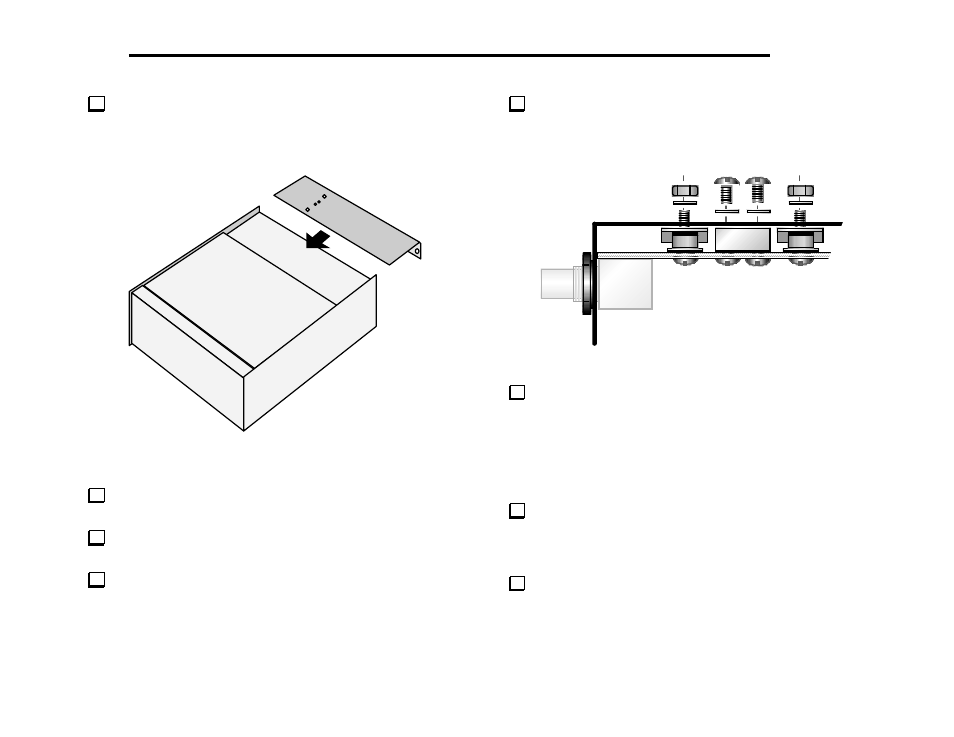

Keeping the K2 on its left side, slip the heat sink over the rear-

panel connectors and into position (Figure 6-33). Figure 6-34 shows

how the heat sink and associated hardware appear in cross-section.

Figure 6-33

Make sure that the four small holes in the heat sink line up with

Q7/Q8 and the 2-D block between them.

Press the Q7/Q8 mounting screws all the way back in so that they

protrude from the heat sink.

Use two chassis screws and two #4 lock washers to secure the

heat sink firmly to the 2-D fastener.

Secure Q7 and Q8 on the bottom of the heat sink using 4-40 nuts

and #4 lock washers. Do not over-tighten the nuts, as this may cause

the thermal pads to scrape against the heat sink, possibly causing a

short to ground.

Figure 6-34

Using an ohmmeter on a low resistance scale, check for a short

from Q7 or Q8 collector to ground. (This test should also be performed

any time the heat sink is removed and re-installed.) If a short is

measured, remove the heat sink and investigate the cause. The most

likely reason for a short is mis-alignment of a shoulder washer or

thermal pad. If a thermal pad or shoulder washer is damaged, it must

be replaced.

There are four more #4 holes in the heat sink: two on the bottom

and two on the back panel. Use four chassis screws to secure the heat

sink to the side panels and RF board at these locations. You may need

to adjust the positions of the 2-D fasteners on the side panels slightly.

Install the washers and finishing nuts that you removed earlier

from the antenna and key jacks. (The antenna jack hardware is shown

installed in Figure 6-34.)

Heat

Sink