Operator’s manual, Liquid flow setup – Great Plains DICKEY-john IntelliAg Planter-Drill Control L3 User Manual

Page 84

OPERATOR’S MANUAL

IntelliAg PDC User 2 & 3

11001-1501-200811

76 / SYSTEM CONFIGURATION

LIQUID FLOW SETUP

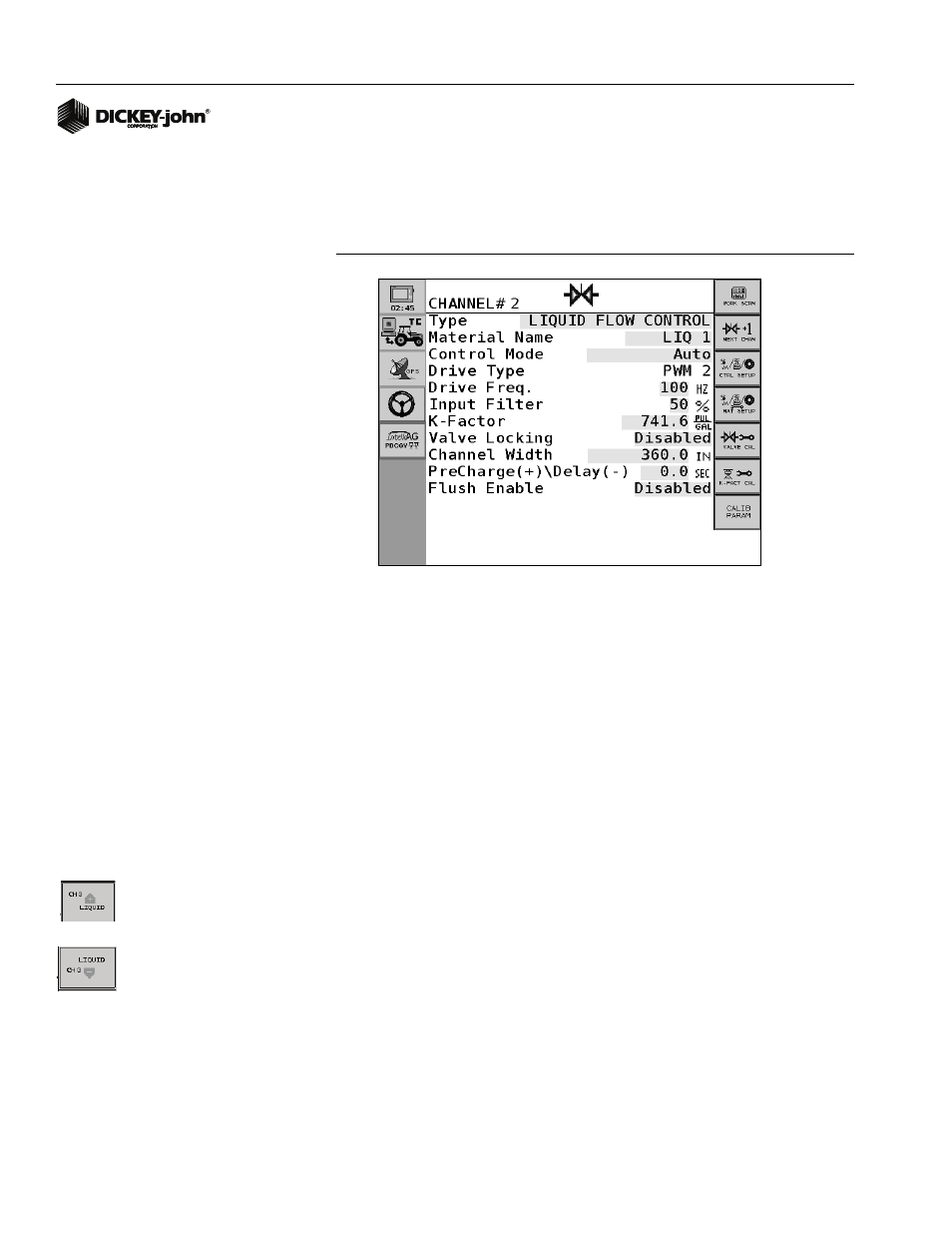

The following constants on the Control Channel Setup screen define the

parameters for Liquid Flow Control.

Figure 47

Control Channel Setup-Liquid Flow Control Setup Example

Type

Select Liquid Flow as the channel type.

Material Name

The Material Name displays only when a material is configured for the same

channel.

Control Mode

AUTO-Control Channel is calculating application rates based on ground

speed and channel width under normal operating conditions.

MANUAL W/FEEDBACK-Overrides the current system when not operating

properly, i.e., faulty coil on hydraulic valve. Using the Increment/

Decrement buttons from the Main Work screen will set the rate for the

control channel. Manual Mode with Feedback will show the actual

application rate being applied based on actual ground speed and constants.

MANUAL W/O FEEDBACK-Overrides the current system when not

operating properly, i.e., bad flow meter. Using the Increment/Decrement

buttons from the Main Work screen will set the rate for the control channel.

No application rate feedback will display.

Drive Type

Three drive type selections are available based on the following:

SERVO

A ball valve or butterfly valve that is driven by an electric motor gearbox and

the valve is installed in the main product delivery line.