Operator’s manual, Row status/row width setup – Great Plains DICKEY-john IntelliAg Planter-Drill Control L3 User Manual

Page 111

OPERATOR’S MANUAL

IntelliAg PDC User 2 & 3

11001-1501-200811

SYSTEM CONFIGURATION / 103

3. If the number of sensors detected on each module is not in agreement

with the # of Rows value entered, an alarm will activate.

– Verify that the # of sensors entered on the Row Assignment screen

match the actual number of sensors connected to the appropriate

module.

– Confirm that all harnessing and sensors are connected properly.

Refer to the Troubleshooting section for further information.

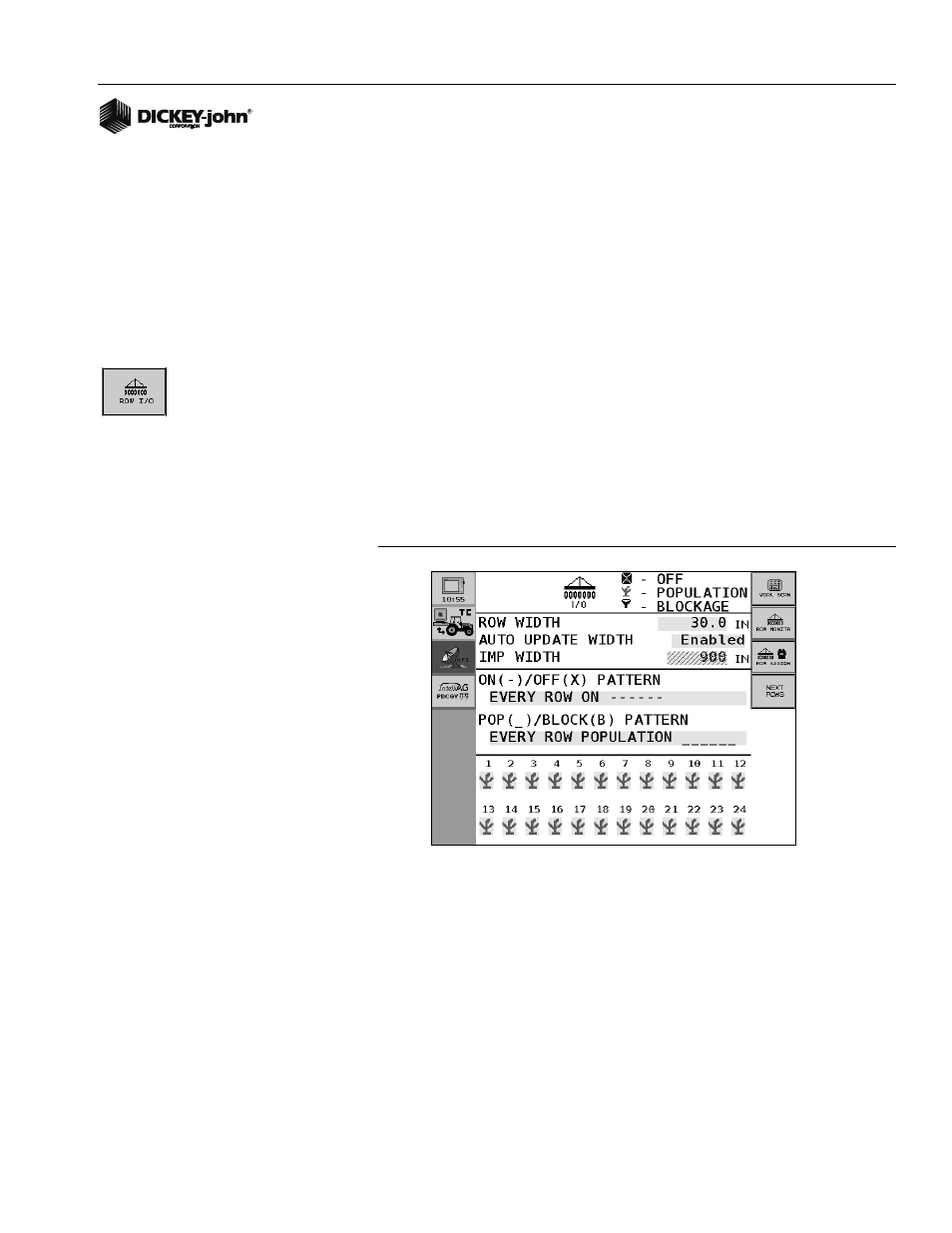

ROW STATUS/ROW WIDTH SETUP

The Row Setup screen controls the rows that are monitored and the

distance between rows and implement width.

Individual rows can be set to ON or OFF. Any detected row can be set to

OFF. Rows set to OFF will remain OFF until they are turned ON again or

are set to ON through the Pattern Select. Rows set to OFF are ignored by

the system and will not report seed data or react to row failures.

1. Press the Row Setup button to access the Row Status/Row Width

Setup screen.

NOTE: The Next Rows button is only

present if more than 24 rows

are configured.

Figure 63

Row Status/Row Width Setup Screen

ROW WIDTH

Row Width is used for seed rate data and control calculations and is the

distance in inches (centimeters) between rows with a resolution of 0.1. This

value updates automatically with changes in the On/Off Pattern Setting

option if the Auto Update Width option is set to Enabled.

AUTO UPDATE WIDTH

Auto Update Width automatically updates the Row Width and Implement

Width settings when changes are made to the Pattern Setting option.