Operator’s manual, Module configuration – Great Plains DICKEY-john IntelliAg Planter-Drill Control L3 User Manual

Page 103

OPERATOR’S MANUAL

IntelliAg PDC User 2 & 3

11001-1501-200811

SYSTEM CONFIGURATION / 95

MODULE CONFIGURATION

System components must be installed correctly and vehicle parameters

entered into the IntelliAg system for effective operation. The following steps

provide guidelines for entering those parameters.

IMPORTANT: Place the master switch in the OFF position to access

and input data into the SETUP/CONFIGURATION mode.

If the current installation does not use a specific component (e.g., pressure

sensors, hoppers, seed sensors) or if the module is not connected in the

system, the module will not display on the screen.

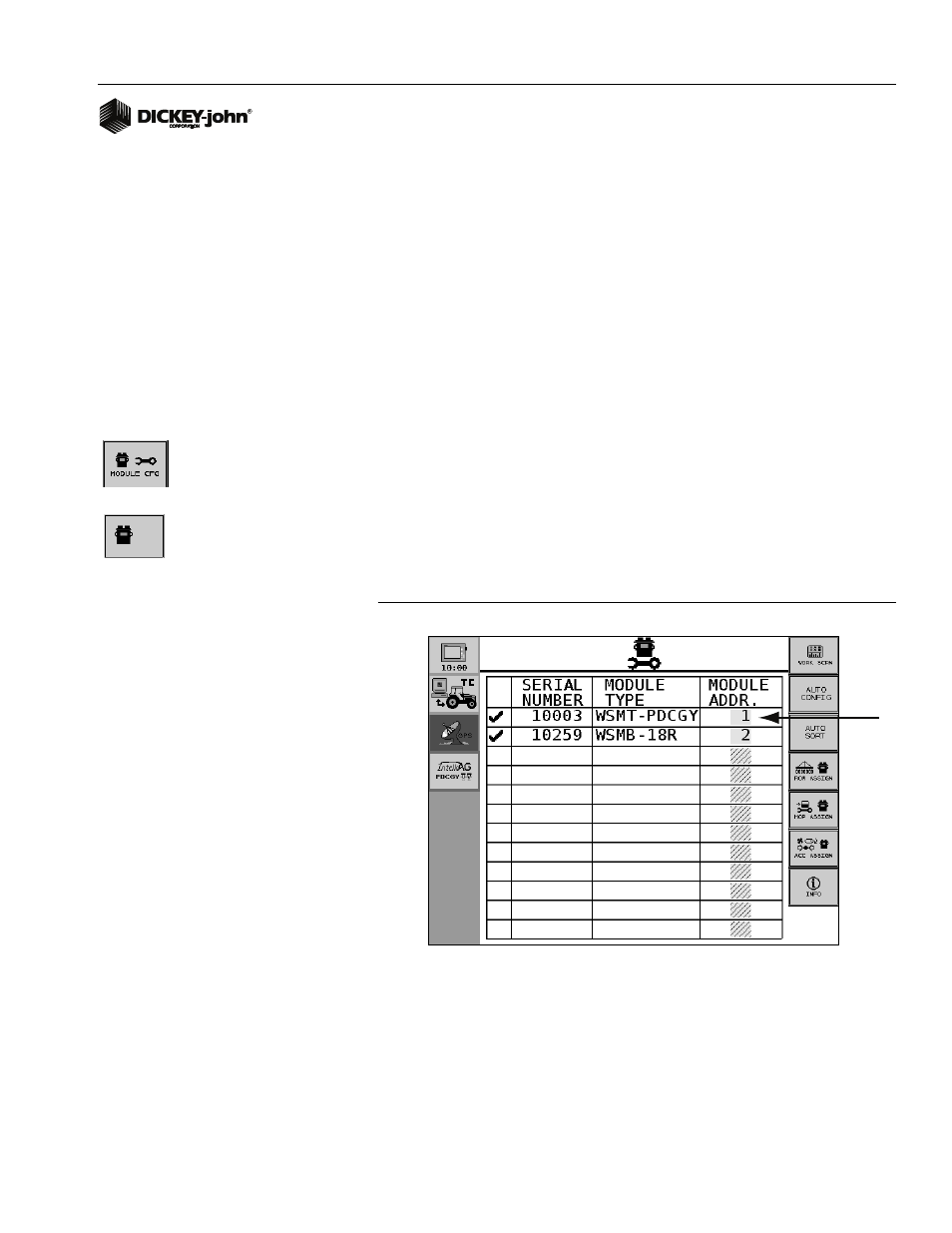

The Module Configuration screen identifies modules on the CAN bus and

the sensors connected to each module. This configuration is necessary for

proper sensor monitoring and self-test operation. A check mark to the left of

each module’s Serial Number identifies that module as active and

communicating module on the bus.

1. From the Main Work screen, press the Module Configuration button

to access the Module Configuration screen.

A Module Next Page button will display if more than 12 modules are

connected. Press the Module Next Page button to display additional

modules.

Figure 57

Module Configuration Screen

SERIAL NUMBER AND MODULE TYPE

Each module present on the CAN bus is identified by the serial number and

module type. The module type corresponds to the identification on the serial

number label attached to that module.

+1

NXT MODULE