Great Plains Inline Ripper Gauge Wheel Jack Kit User Manual

General information, Assembly instructions, Inline ripper gauge wheel jack kit

© Copyright 2005 Printed

Great Plains Mfg., Inc.

Used with:

Installation Instructions

596-158M

3-8 Shank Sub-Soiler Inline Ripper

Inline Ripper Gauge Wheel Jack Kit

• 3-8 Shank Sub-Soiler Inline Ripper

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

the lives of others depend on it!

!!

These instructions explain how to install the Inline Rip-

per Gauge Wheel Jack Kit. The Inline Ripper Gauge

Wheel Jack Kit allows for jacks to be added to the In-

line Ripper Gauge Wheels to adjust the depth of the

ripper. These instructions apply to:

596-157A

Inline Ripper Gauge Wheel Jack Kit

Manual Update

Refer to the 3-8 Shank Sub-Soiler Inline Ripper op-

erator’s manual for detailed information on safely

operating, adjusting, troubleshooting and maintaining

the Inline Ripper Gauge Wheel Jack. Refer to the

parts manual for part identification.

596-086M

Operator’s Manual

596-086P

Parts Manual

5/4/2005

Before You Start

Page 7 is a detailed listing of parts included in the

Inline Ripper Gauge Wheel Jack Kit. Use this list

to inventory parts received.

Tools Required

• Basic Hand Tools

• Welder

• DA Grinder

Assembly Instructions

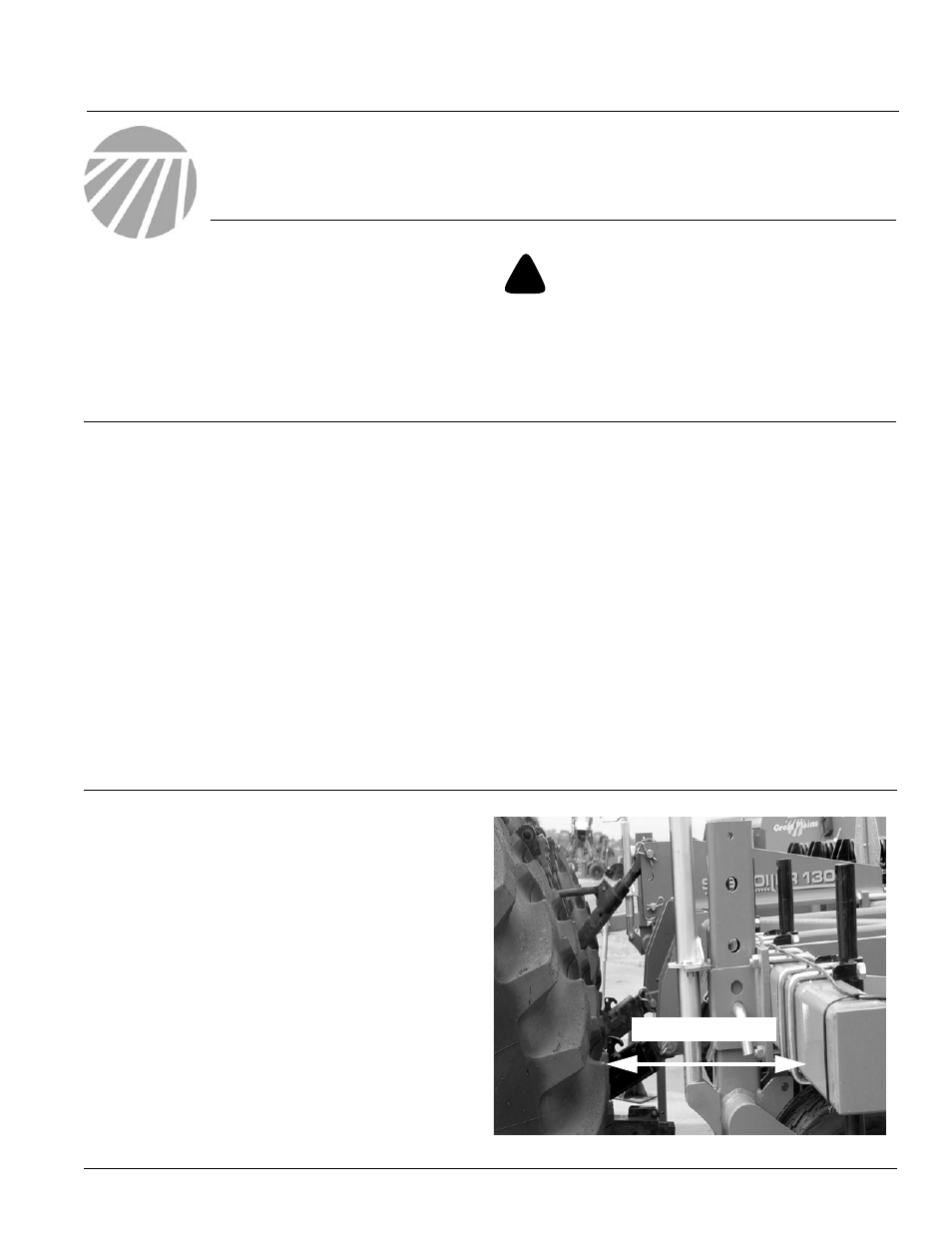

Refer to Figure 1

NOTE: Mounting the jack to the gauge wheel arm may

cause clearance problems with the Great Plains Sub-

Soiler Hitch or with tractor tires if the ripper is 3-point

mounted. If gauge mounts line up with tires or

hitch, be sure there is at least 12" clearance be-

tween front of the frame tube and tires or hitch. If

the 12" clearance exists, the gauge wheels will mount

on the front side of the front frame tube. Please refer to

the following instructions on page 2. If there is not 12"

clearance, the gauge wheels will need moved out to-

wards the end of the frame or need mounted on the

back side of the front frame tube. Please refer to page

4 for these instructions.

12" Clearance

Figure 1

23176