Operator’s manual, Troubleshooting & alarms / 163 – Great Plains DICKEY-john IntelliAg Planter-Drill Control L3 User Manual

Page 171

OPERATOR’S MANUAL

IntelliAg PDC User 2 & 3

11001-1501-200811

TROUBLESHOOTING & ALARMS / 163

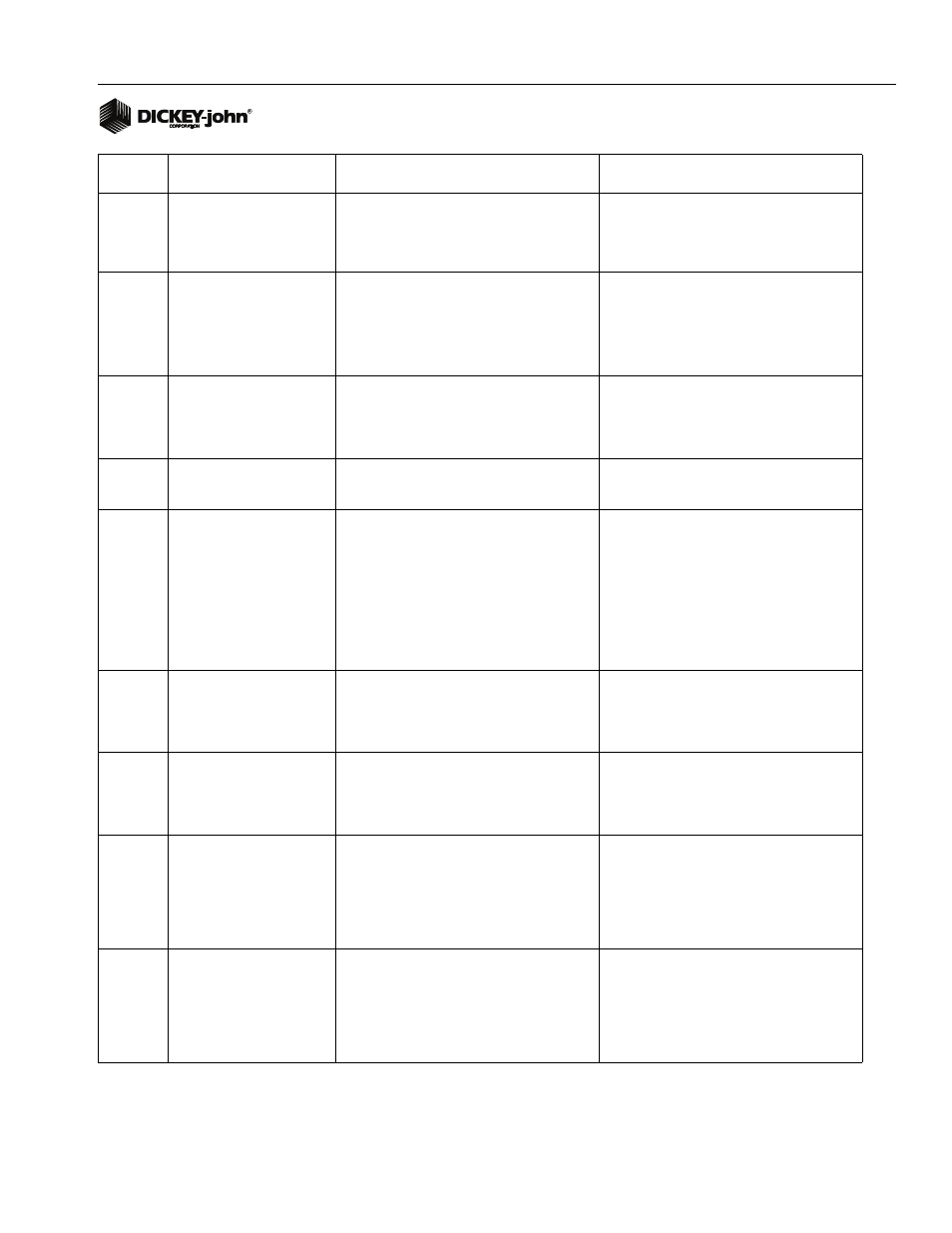

ALARM

#

ALARM

PROBABLE CAUSE

CORRECTIVE ACTION

1

Software Task Stack

Overflow Alarm

1. Internal system software error.

1. Cycle system power OFF/ON. If condition

persists, contact DICKEY-john Technical

Support (1-800-637-3302) or DICKEY-john

Europe (011-33-141-192189).

2

Software System Stack

Overflow Alarm

1. Internal system software error.

1. Cycle system power OFF/ON. If

condition persists, contact DICKEY-john

Technical Support (1-800-637-3302) or

DICKEY-john Europe

(011-33-141-192189).

3

VT Out of Memory Alarm

THE ECU MEMORY REQUIREMENTS

ARE GREATER THAN THE VIRTUAL

TERMINAL CAN HANDLE.

1. Remove any unnecessary ECU’s

2. Contact DICKEY-john Technical Support

(1-800-637-3302) or DICKEY-john Europe

(011-33-141-192189) for updated

hardware.

4

Software Version Does

Not Support this

Configuration Alarm

1. Occurs if new software is loaded and

does not support the configuration of the

hardware it is loaded on.

1. Record software and model information

listed below.

2. Contact dealer for software update.

202

Ground Speed Failure

Alarm

ONLY ACTIVE IN PLANTER MONITOR

MODE. SEEDS ARE DETECTED WHEN

THERE IS NO GROUND SPEED.

1. Incorrect speed source setting or

calibration.

2. Defective speed sensor or harness.

3. Defective module or virtual terminal.

1. Verify correct speed source setting and

speed calibration on the Ground Speed

Calibration screen.

2. Inspect speed sensor/harness for

damage or replace speed sensor.

3. Replace module or virtual terminal.

203

Continuous Test Failure

Alarm

CONTROL CONDITIONS EXCEED THE

DISK RPM LIMITS.

1. Test speed setting is set too high or low.

2. Disk Hi and/or Disk Low settings are

incorrect.

1. Enter an appropriate Test Speed.

2. Verify or enter appropriate Disk Hi and/or

Disk Low values.

204

5 Revolution Test Failure

Alarm

CONTROL CONDITIONS EXCEED THE

DISK RPM LIMITS.

1. Test Speed setting is set too high or low.

2. Disk Hi and/or Disk Low settings are

incorrect.

1. Enter an appropriate test speed.

2. Verify or enter appropriate Disk Hi and/or

Disk Low values.

205

Channel Failure Alarm

1. Defective control valve.

2. Defective feedback sensor.

3. Defective module harness or module

harness fuse.

4. Defective module.

1. Inspect control valve for damage or

replace.

2. Inspect feedback sensor for damage or

replace.

3. Inspect module harness for damage.

Replace harness fuse.

4. Inspect module for damage or replace.

206

Channel Unable to

Control Alarm

1. Incorrect channel settings.

2. Incorrect feedback sensor installation.

3. Defective feedback sensor.

1. Verify correct setup constants on the

Channel Configuration screen. Perform a

valve calibration.

2. Verify correct installation of the feedback

sensor.

3. Inspect feedback sensor for damage or

replace.