Operator’s manual, Troubleshooting & alarms / 167 – Great Plains DICKEY-john IntelliAg Planter-Drill Control L3 User Manual

Page 175

OPERATOR’S MANUAL

IntelliAg PDC User 2 & 3

11001-1501-200811

TROUBLESHOOTING & ALARMS / 167

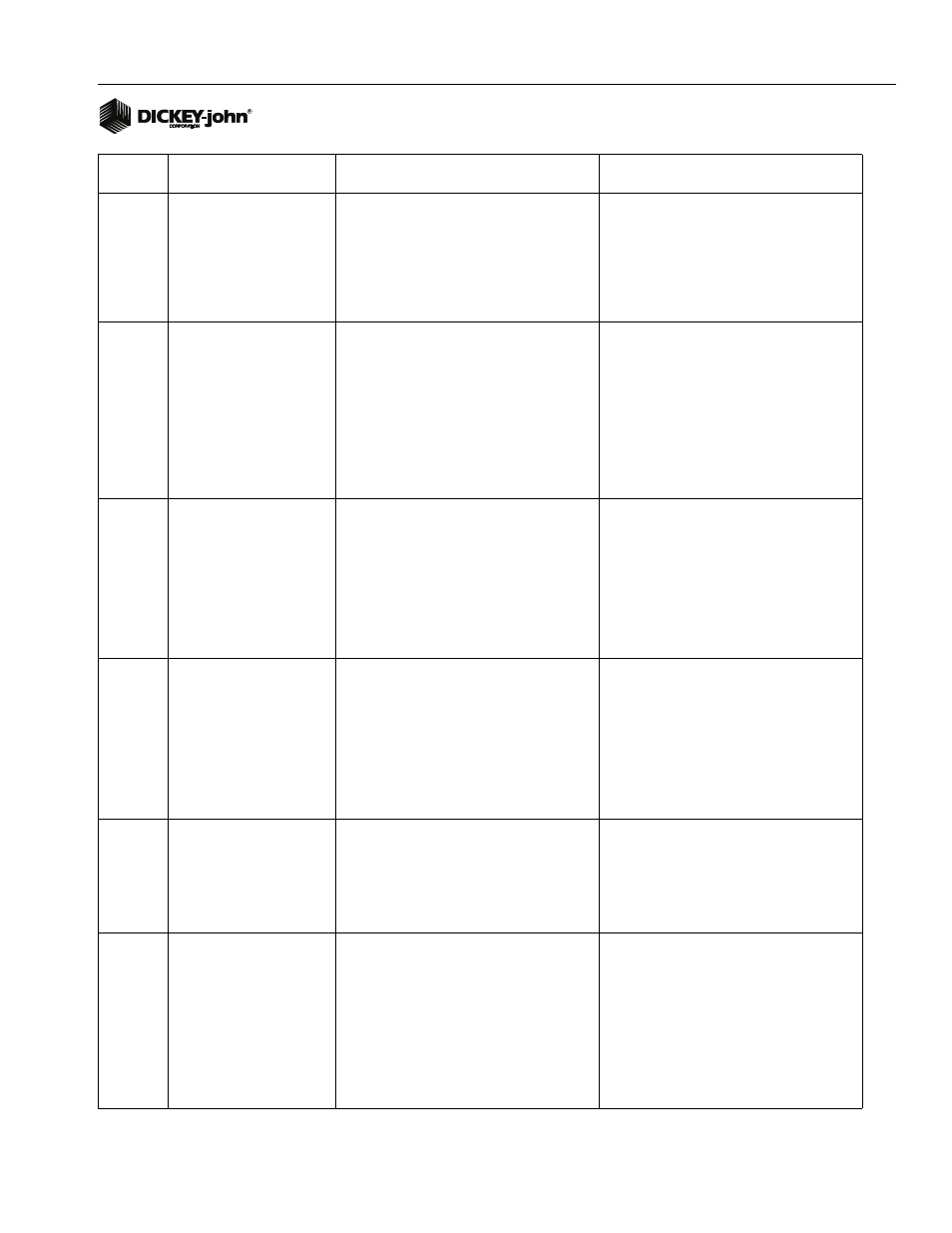

227

RPM Sensor Low Limit

Exceeded Alarm

SENSED RPM BELOW THE LOW ALARM

SETTING ON THE RPM SETUP SCREEN.

1. Implement malfunction or incorrect

setup.

2. Defective RPM sensor.

3. Defective module harness or module.

1. Verify proper implement operation/setup.

2. Inspect RPM sensor for damage.

Replace if necessary.

3. Inspect module for damage. Replace if

necessary.

228

Hopper Sensor Detection

Alarm

NUMBER OF HOPPER SENSORS

CONNECTED DOES NOT AGREE WITH

THE NUMBER OF SENSORS

CONFIGURED ON THE HOPPER

SENSOR CONFIGURATION SCREEN.

1. Defective hopper sensor.

2. Defective module or damaged module

harness.

3. Additional hopper sensors detected.

1. Inspect hopper sensor for damage or

replace.

2. Inspect module and/or module harness

for damage. Replace if necessary.

3. Verify correct # HOPP setting for each

module.

229

Hopper Sensors Installed

Incorrectly Alarm

HOPPER SENSORS ARE NOT

INSTALLED SEQUENTIALLY ON A

MODULE.

1. Incorrect hopper sensor connections.

2. Defective hopper sensor.

3. Defective module or damaged module

harness.

1. Verify hopper sensors are connected

sequentially on all modules as instructed in

INSTALLATION.

2. Inspect hopper sensor for damage or

replace.

3. Inspect module and/or module harness

for damage. Replace if necessary.

230

Pressure Sensors

Installed Incorrectly Alarm

PRESSURE SENSORS ARE NOT

INSTALLED SEQUENTIALLY ON A

MODULE.

1. Incorrect pressure sensor connections.

2. Defective pressure sensor.

3. Defective module or damaged module

harness.

1. Verify pressure sensors are connected

sequentially on all modules as instructed in

INSTALLATION.

2. Inspect pressure sensor for damage or

replace.

3. Inspect module and/or module harness

for damage. Replace if necessary.

231

Seeding Detected on a

Tramlined Row Alarm

Occurs if a tramlined row does not shut off

the row unit and seeds continue to be

detected. (Only possible if system supports

tramlining).

1. Output to row mapping is assigned

incorrectly.

2. Seed sensor malfunction.

1. Check output row mapping.

2. Check seed sensor to ensure no false

triggering.

3. Inspect and verify Tramline output is

shutting off seeds correctly.

232

RPM Sensor Low Limit

Exceeded With Control

Channel Shutdown Alarm

RPM HAS DROPPED BELOW THE

DISABLE CONTROL ON LOW ALARM

SETTING ON THE ACCESSORY SETUP

SCREEN.

1. Defective RPM sensor.

2. Damaged module harness.

3. Defective module.

4. Low RPM

1. Inspect RPM sensor for damage.

Replace if necessary.

2. Inspect module harness for damage.

Repair or replace.

3. Inspect module for damage. Replace if

necessary.

4. Increase RPM.

ALARM

#

ALARM

PROBABLE CAUSE

CORRECTIVE ACTION