Operator’s manual, 168 / troubleshooting & alarms – Great Plains DICKEY-john IntelliAg Planter-Drill Control L3 User Manual

Page 176

OPERATOR’S MANUAL

IntelliAg PDC User 2 & 3

11001-1501-200811

168 / TROUBLESHOOTING & ALARMS

233

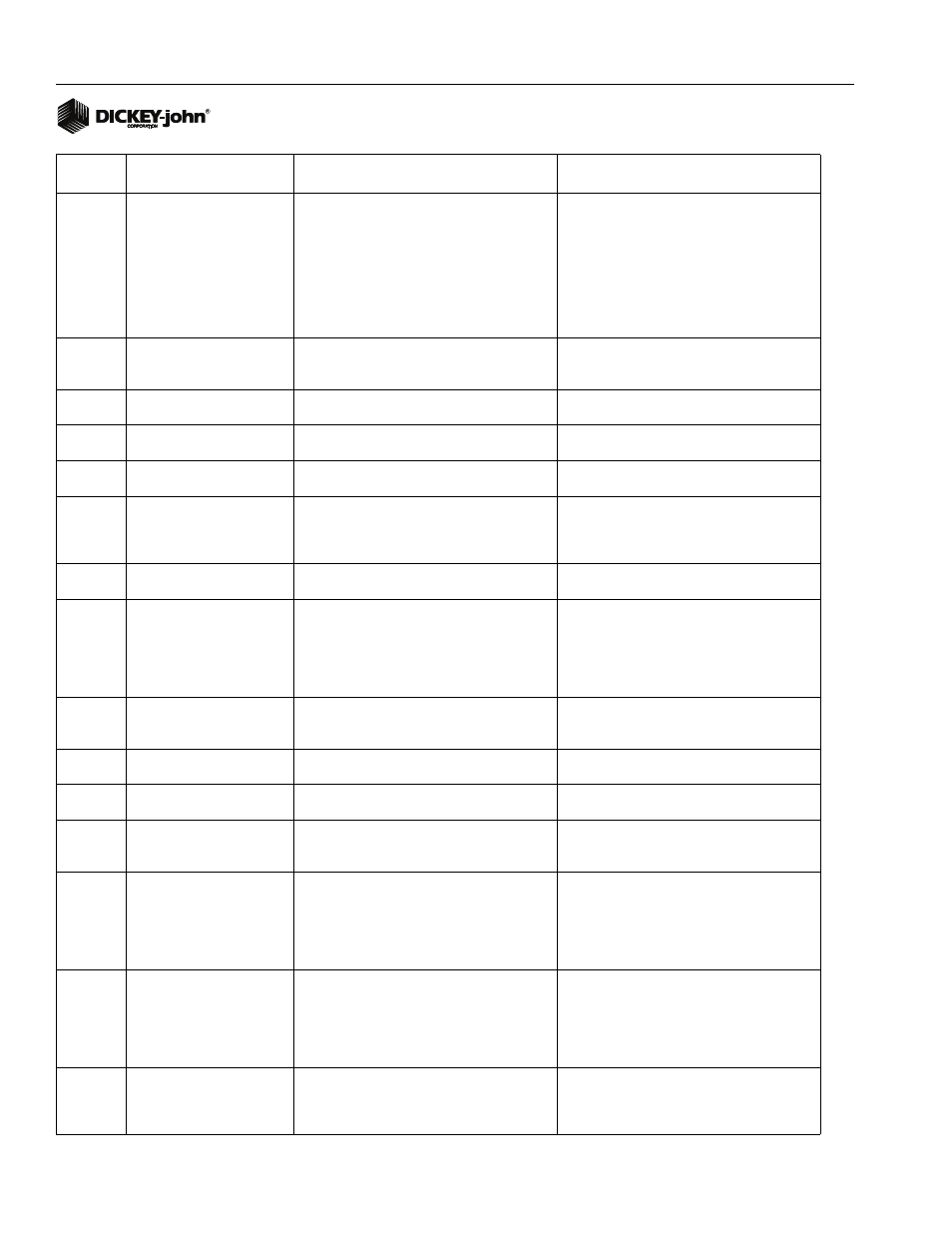

Channel Activation Alarm

CHANNEL DELAY OR PRECHARGE IS

ENABLED. DURING THIS THE CONTROL

WILL RUN WITHOUT GROUND SPEED

OR WITHOUT THE IMPLEMENT DOWN.

1. Acknowledge alarm to activate control

channels.

2

.

Acknoweldge alarm and disable Delay or

Precharge to stop control.

235

New Member Module

Detected Alarm

1. New member module has been found.

1. Assign sensors to the new module at the

Module Configuration Setup screen and its

position.

236

Intermittent Member

Module Detected Alarm

1. A member module that had previously

failed communication has come online.

1. Inspect harness connections to this

module.

237

Product Level Low Alarm

1. Calculated product level has dropped

below alarm level.

1. Fill product bin and reset level.

240

Seeding Detected on a

Control Off Row Alarm

1. Channel turned off and seed continues

to be detected.

1. Check seed dispensing unit for proper

shut off.

241

Control Not Active With

Implement Lowered and

Speed

1. Control will not operate while on a setup

screen.

1. Navigate to the Work Screen to activate

the control.

2. Raise implement and stop forward speed

to clear alarm.

246

Master Switch Softkey

Press Alarm

1. Warning of action associated with

keypress.

1. Press Control Start key to activate

control.

249

Control Channel

Activation Alarm

1. Controls will run without ground speed or

without implement lowered. Channel

Manual Mode or Precharge is enabled.

During this the control will run without

ground speed or without the implement

down.

1. Acknowledge alarm to activate control

channels.

2. Acknowledge alarm and disable manual

or precharge to stop control.

251

New Hardware Detected

Alarm

1. New hardware detected that requires

system to be rebooted to acknowledge

hardware.

1. Cycle system power to complete

hardware install.

253

Monitor Channel High

Limit Exceeded Alarm

1. High limit set incorrectly.

2. Transmission not set correctly.

1. Verify high limit.

2. Verify transmission setting.

254

Monitor Channel Low

Limit Exceeded Alarm

1. Low limit set incorrectly.

2. Transmission not set correctly.

1. Verify low limit.

2. Verify transmission setting.

255

Channel Invalid Material

Alarm

1. There is no material defined with a type

that matches the selected control channel

type.

1. Create a material with the channel type.

260

Control Channel Failure

Alarm

1. Control channel is not responding.

1. Cycle Master Switch or implement switch

to restart the control channel.

2. Verify drive is connected and engaged.

3. Check feedback sensor for damage.

4. Check harness for damage.

5. Check module for damage.

261

Control Channel Unable

to Control Alarm

1. Control Channel cannot control to the

specified rate.

1. Inspect control channel setup.

2. Perform new valve calibration.

3. Check feedback sensor for damage.

4. Check control valve for damage.

5. Check harness for damage.

6. Check module for damage.

262

RPM Control Channel is

off Alarm

1. RPM Channels are off. System may not

operate properly.

1. Acknowledge alarm to leave RPM

control channels off.

2. Press “CHAN ON” to turn all RPM

channels on.

ALARM

#

ALARM

PROBABLE CAUSE

CORRECTIVE ACTION