2 plus/minus signs and directions – Festo Электромотор MTR-DCI User Manual

Page 43

1. System overview

1-21

Festo P.BE-MTR-DCI-DN-EN en 1209a

Point of reference

Calculation rule

Axis zero point

AZ

= REF

+ a

Project zero point

PZ

= AZ

+ d

= (REF

+ a) + d

Lower software end posi-

tion

LSE

= AZ

+ b

= (REF

+ a) + b

Upper software end posi-

tion

USE

= AZ

+ c

= (REF

+ a) + c

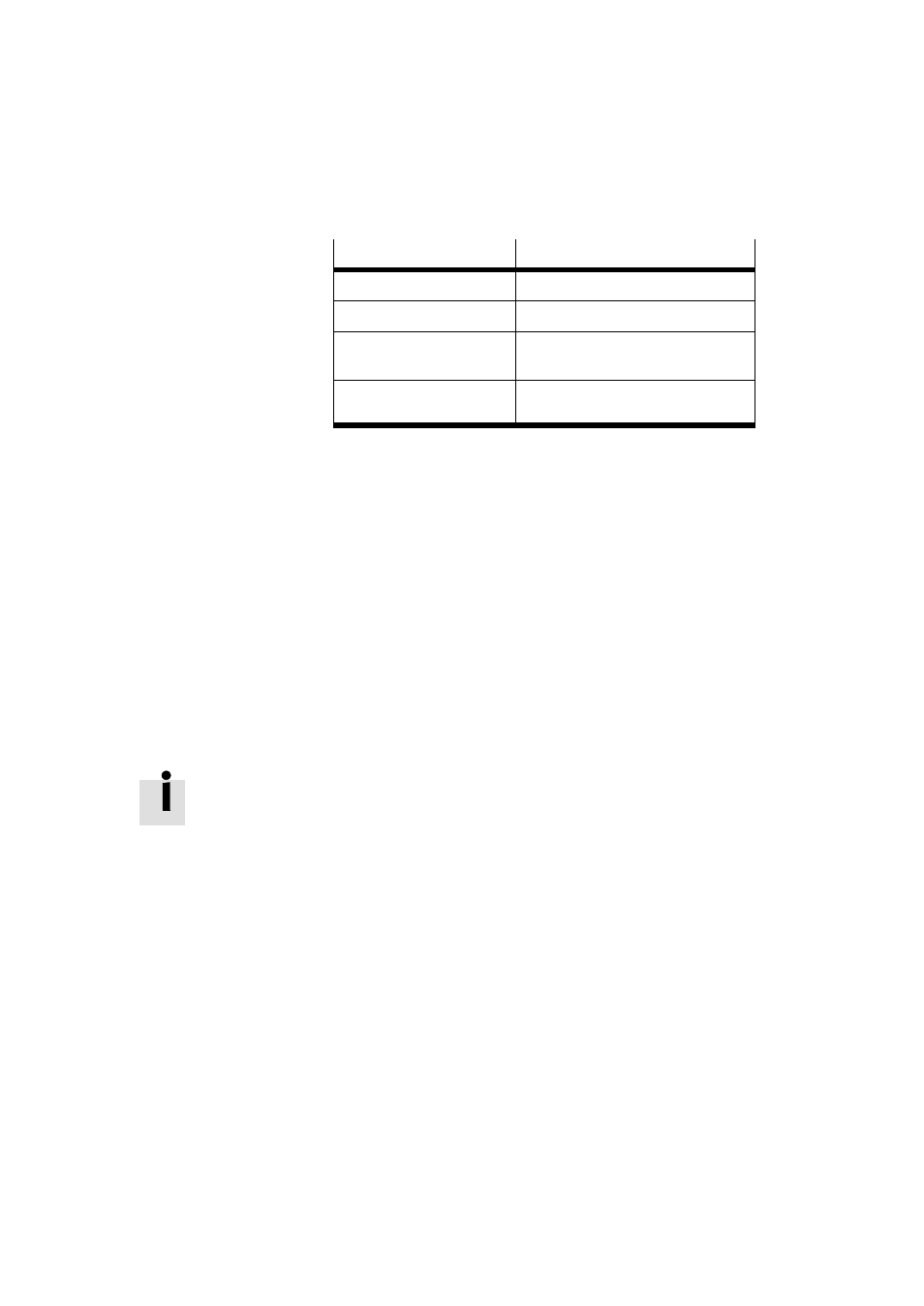

Tab. 1/7: Calculation regulations for a dimensional reference system with incremental

measurement systems

1.6.2

Plus/minus signs and directions

All offsets and position values are vectors (with a given alge-

braic sign, + or -). The +/- operating direction of the vectors

can be assigned to the rotation direction of the motor shaft

(visual inspection of the motor shaft). The factory settings are

“+” for clockwise rotation and “-” for anticlockwise rotation.

The active direction can be reversed at the control panel (see

chapter 4.5.2) or via FCT. This can be useful when using

angular gear units or toothed belt drives. Homing must be

carried out again if the direction is reversed.

The direction in which the work load moves depends on the

gearing, the spindle type (left/right-rotating), the algebraic

signs on the positioning specifications (+/-), and the cur-

rently set active direction: