Dwyer UXF2 User Manual

Page 29

-

19

-

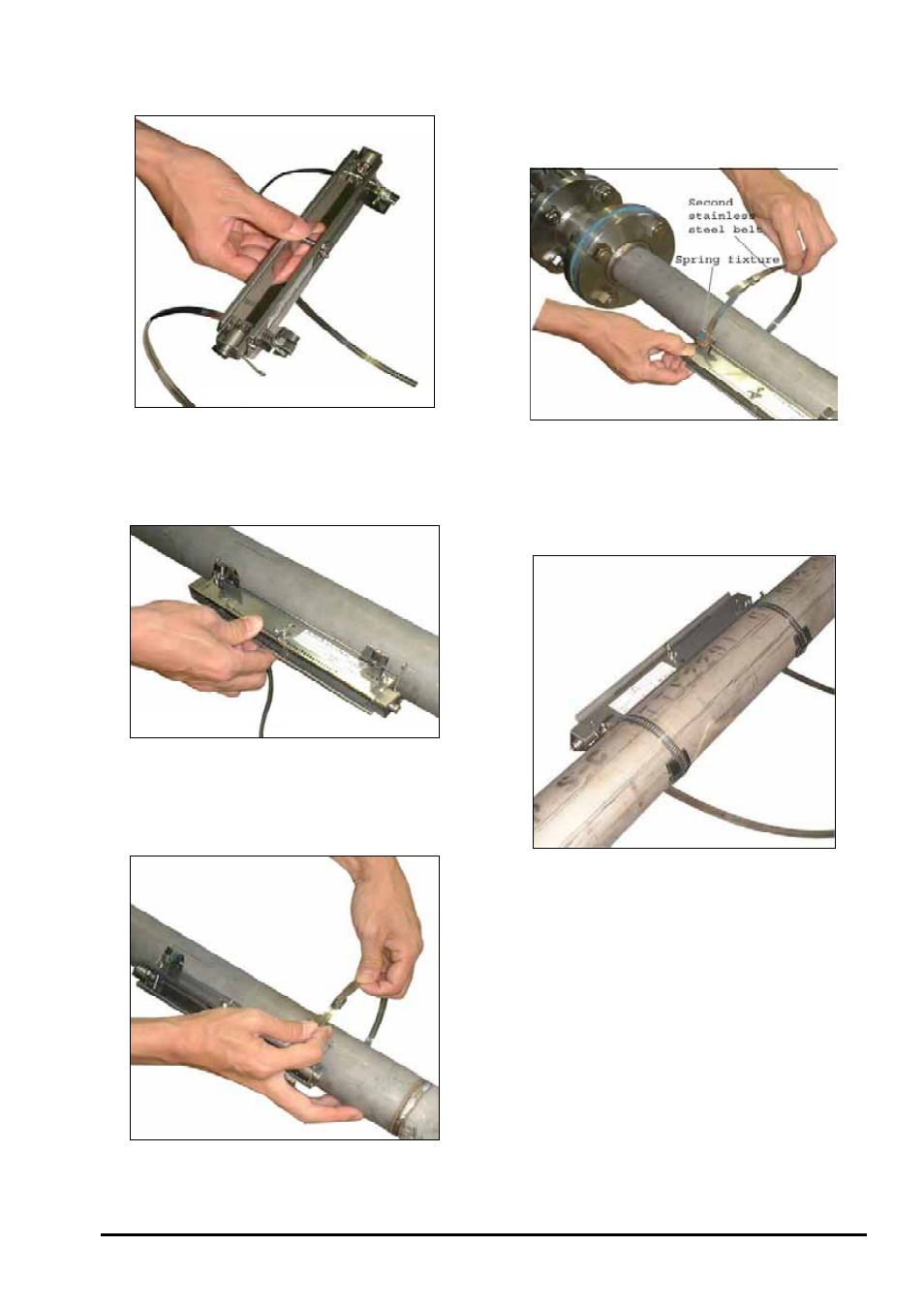

(3) Make sure the obtained status is as shown in Fig. 3-4.

Fig. 3-4

(4) As shown in Fig. 3-5, apply the frame on the pipe

section subjected to a surface treatment.

Fig. 3-5

(5) Temporarily tighten the first stainless steel belt on the

pipe as shown in Fig. 3-6.

Fig. 3-6

(6) Adjust the frame so as to be in parallel with the pipe,

put the spring fixture to the side of the frame as

shown in Fig. 3-7, and tighten the stainless steel belt

so that the frame will tightly be fitted.

Fig. 3-7

(7) After tightening both stainless steel belts, slide the

spring fixture to the opposite to the frame as shown in

Fig. 3-8.

Fig. 3-8

Note: When removing the frame set to the piping and

set it to a different position, use new stainless

steel belts.

BULLETIN F-70

- 166T (1 page)

- 160S (2 pages)

- PAFS-1000 (1 page)

- 160F (2 pages)

- Mark II WSI (4 pages)

- MW-1 (2 pages)

- 89088 (12 pages)

- 660 (2 pages)

- 670 (16 pages)

- FLST (4 pages)

- AFG (6 pages)

- FAFM (2 pages)

- DAFM (2 pages)

- STRA (4 pages)

- 530 (2 pages)

- AVFS (2 pages)

- 641RM (4 pages)

- 641B (4 pages)

- 641 (4 pages)

- VTT (2 pages)

- SFI-700 (2 pages)

- GFM (32 pages)

- GFC (40 pages)

- DMF (44 pages)

- GFM2 (20 pages)

- GFM3 (22 pages)

- TFP-LI (30 pages)

- TFP-GI (27 pages)

- TBS (7 pages)

- HFT (4 pages)

- CAM (6 pages)

- PWD (3 pages)

- BAT (3 pages)

- FPCA (4 pages)

- FPCA (2 pages)

- SPK (4 pages)

- MFS (8 pages)

- LOFM (3 pages)

- FLMG (12 pages)

- MFS2 (16 pages)

- PFT (4 pages)

- IPFS (7 pages)

- UFB (48 pages)

- UFC (56 pages)

- Series PUB (44 pages)