If keying is abnormal, If measurement value is abnormal – Dwyer UXF2 User Manual

Page 110

- 100 -

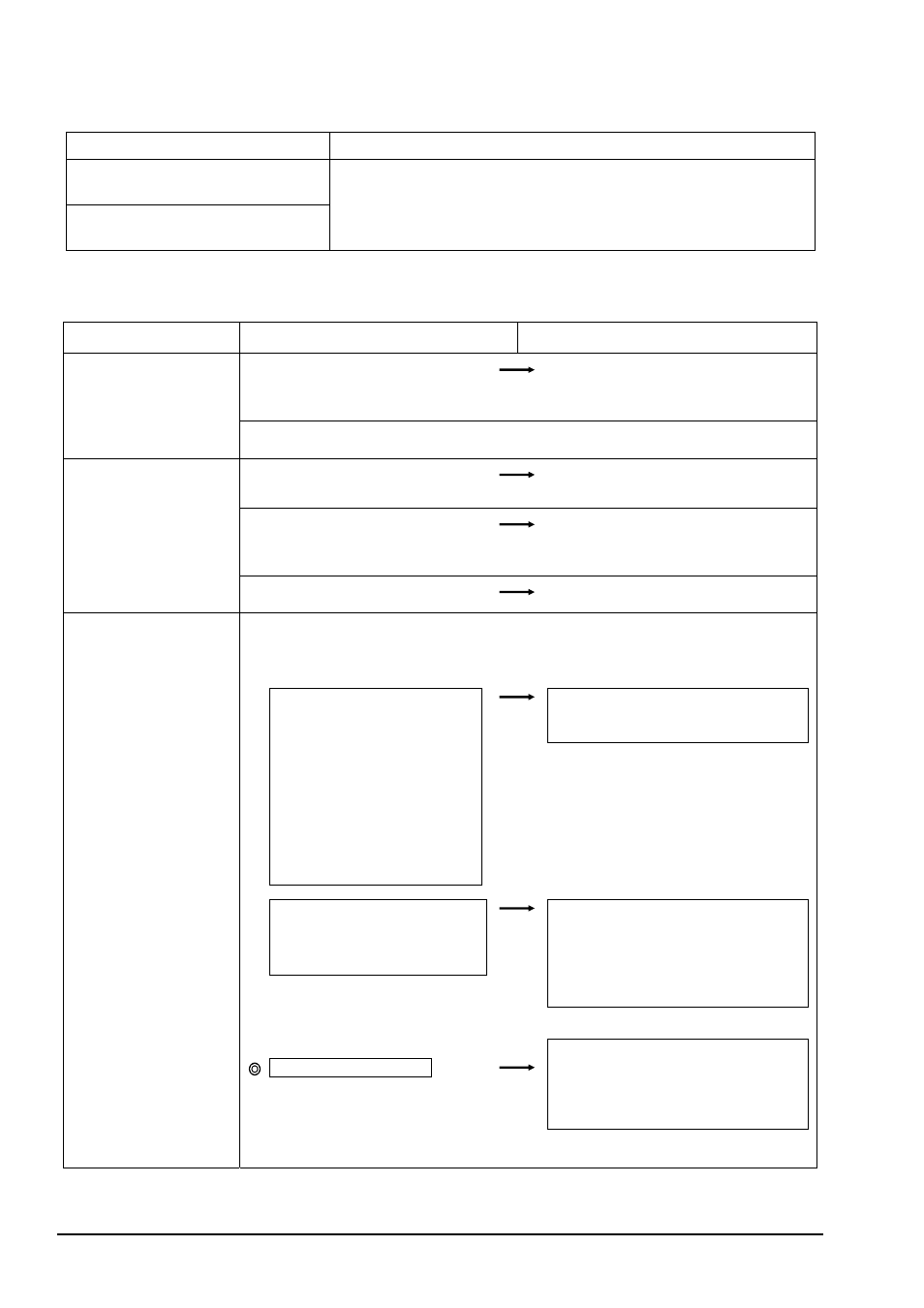

5.7.2. If keying is abnormal

Symptom Cause

Keying (buttons) not registering.

z

Hardware error. Refer to "Section 5.7.6. Remedying a hardware

fault".

Certain key is not responding.

Action is not as defined.

5.7.3. If measurement value is abnormal

Symptom Cause

Remedy

z Connection between main unit and

sensor units (upstream,

downstream) are backwards.

Connect correctly.

Minus (–) symbol

indicated on

measurement value.

z Switch cable connections (upstream & downstream).

z Straight part of pipe is inadequate

Select where 10D upstream and 5D

downstream of detector is available.

z Pump, valve, tee, etc which

disturb the flow are located

nearby.

Separate them to at least 30D.

Measurement value

fluctuates excessively

while flow rate is

constant.

z Pulsation exists actually.

Set the damping to longer response time.

Ultrasonic wave is not propagated into piping properly, so reading is held.

1. Installation is poor.

Measurement value does

not change with actual

rate change (LED lit red).

z

Pipe specifications are

wrong.

z

Sensor is mounted on

welding.

z

Sensor mounting

dimensions are wrong.

z

Silicone filler is not

applied properly when

mounting the sensor

z

Sensor cable connection is

poor.

Upon checking, remove the sensor,

apply silicone filler, and slightly off-

position the sensor.

Sensor mounting is poor

z

Mounting dimensions.

z

There is a gap between

sensor and piping.

z

Mount the sensor in parallel with

pipe, allowing correct sensor unit

spacing.

z

Mount the sensor properly so that

it is kept in close contact with the

pipe.

2. Pipe or fluid is problematic.

Not completely filled.

Locate a place which is completely

filled on the same piping line, and shift

the sensor there.

z

Mount the sensor at lowermost

position on piping line.

(continued)

BULLETIN F-70