Operation position i/o assignments – IAI America XSEL-KE User Manual

Page 280

265

Part 4 Commands

(2) Explanation of the operation

1. Move to the standby point and wait for a start input.

2. Move to the load feed point after a start input is received.

3. The Z-axis comes down and the air chuck clamps the load.

4. The Z-axis rises and moves to above the pallet.

5. The Z-axis comes down and releases the load.

6. The Z-axis rises and moves to above the load feed point.

7. When the pallet becomes full, a pallet-completion indicator signal is output. The axes move to

P18 and then wait for restart.

The above operation will be repeated. The operation position, external I/O assignments and

operation flow chart of this operation are shown below:

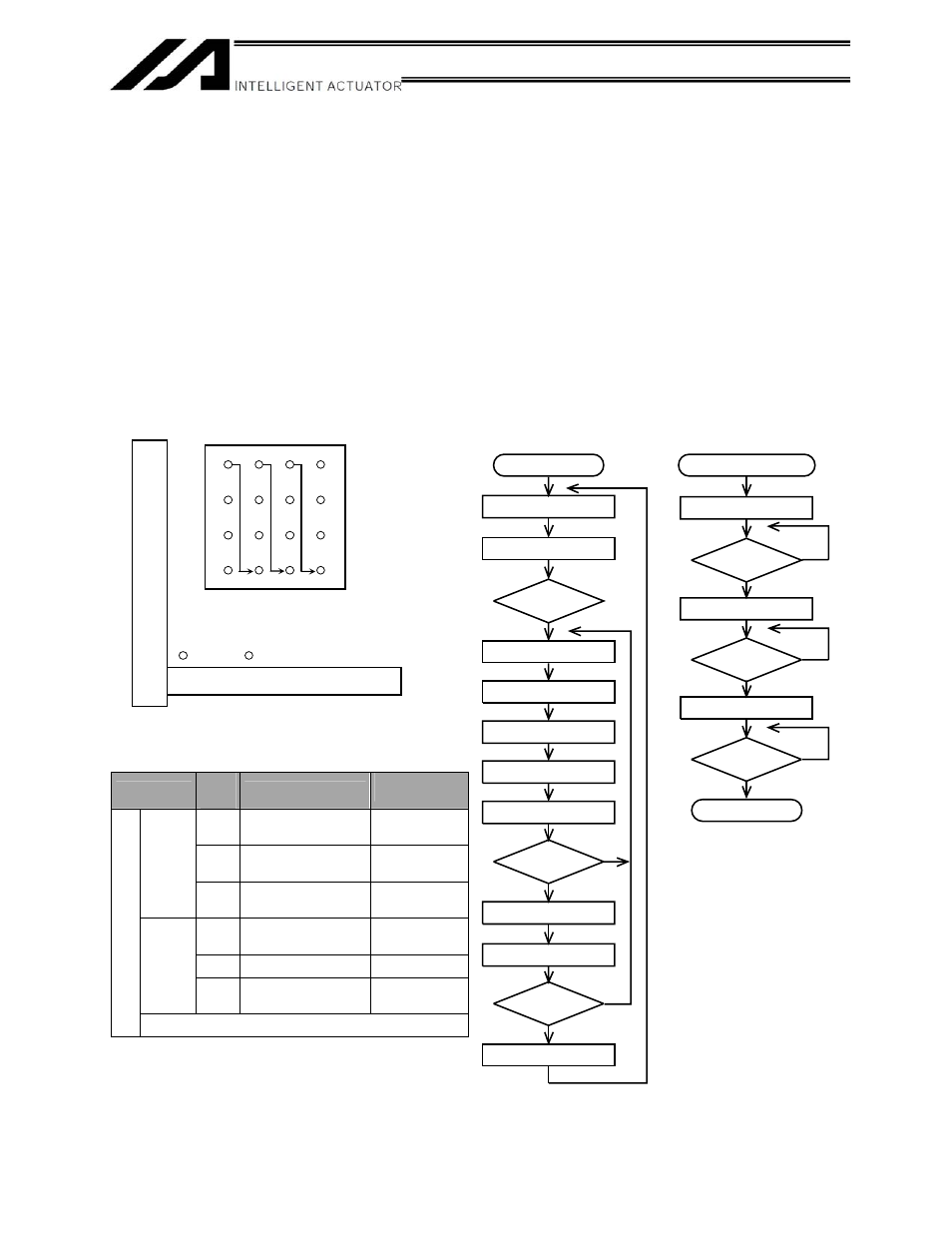

Operation Position

I/O Assignments

Category

I/O

No.

Signal name

Specification

16

Z-axis cylinder

upper limit

Proximity

SW

17

Z-axis cylinder

lower limit

Proximity

SW

Input

18 Start

Pushbutton

switch

309

Z-axis cylinder

SV

24 VDC

310 Z-axis chuck SV 24 VDC

Output

311

Pallet-completion

indicator

24 VDC

X-SEL

* Flag is used from 600.

Pallet specifications

Axis-1 direction: 20-mm pitch

Axis-2 direction: 30-mm pitch

Operation Flow Chart

Start

Clear variable

Move to position No. 18

Wait for

input of 18

Move to position No. 17

Call chuck subroutine

Move to position No. 1

Call chuck subroutine

Increment axis-1 offset by

20 mm

Variable

300 = 80

Clear variable 300

Increment axis-2 offset by

30 mm

Variable

301 = 120

Completion signal ON

Chuck subroutine

Cylinder down

Lower limit

Reverse chuck output

Timer

Cylinder up

Upper limit

End of subroutine

N

N

N

N

N

Axis

1

Axis 2

P18 P17

P1

n

n

n

n

n

n

n

n

n

n

n

n

Y

Y

Y

(0.5s)

Y

Y