IAI America PCON-CFA User Manual

Page 245

4. SCON-CA

239

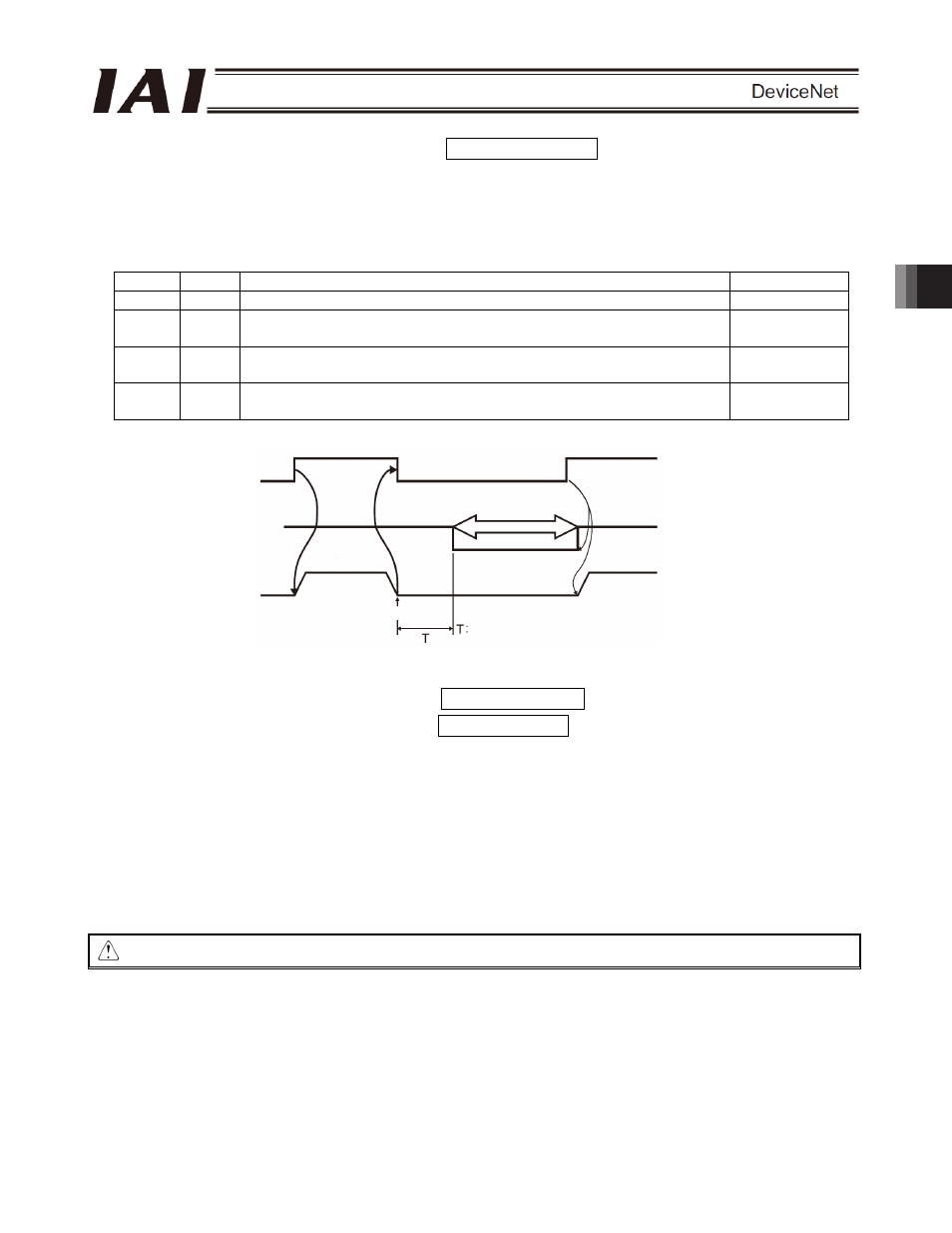

(31) Standstill Mode Selection (ASO0, ASO1) PLC Output Signals

Select the stop mode to be applied while the actuator is standing by to move to the next position after completing

a positioning.

If the actuator remains standstill for a long time, the servo is turned off automatically to lower the power

consumption.

For details, refer to the operation manual for your controller.

ASO1 ASO0

Standstill

mode

Remarks

OFF OFF Disabled

(Factory

setting)

OFF

ON

Auto servo OFF mode

T in the chart below corresponds to the setting of parameter No. 36.

ON

OFF

Auto servo OFF mode

T in the chart below corresponds to the setting of parameter No. 37.

ON

ON

Auto servo OFF mode

T in the chart below corresponds to the setting of parameter No. 38.

(32) Load Cell Calibration Command (CLBR) PLC Output Signal

Load Cell Calibration Complete (CEND) PLC Input Signal

The factory setting for the load cell is 0 N when no load is applied. If you want to use the loaded condition as the

reference (0 N), perform the following calibration. Also perform this calibration in other conditions as necessary

(such as during readjustment, inspection, etc.).

[1] Stop the operation. (Calibration cannot be performed while any axis is operating, pushing a work part or

paused, in which case an attempt to perform calibration will generate a 0E1 (load cell calibration error) alarm.

[2] Turn ON the load cell calibration signal (CLBR) and keep it ON for at least 20 ms.

[3] Once the calibration is complete, the calibration complete signal (CEND) turns ON. Thereafter, turn OFF the

CLBR signal.

If the calibration was not successful, a 0E1 (load cell calibration error) alarm generates.

Caution:

Normal operation commands are not accepted while the CLBR signal is ON.

Movement command

Servo status

Actuator movement

Servo ON status

Auto servo OFF mode

(A green LED blinks.)

Delay time until the servo turns off after

completion of positioning (sec)

Target position