Hint, Precautions, Performance specifications calculation method – Omron SYSMAC CP CP1E-N@@D@-@ User Manual

Page 296: 2 instructions

2 Instructions

2-260

CP1E CPU Unit Instructions Reference Manual(W483)

Hint

• PIDAT(191) is executed as if the execution condition was a STOP-RUN signal. PID calculations are

executed when the execution condition remains ON for the next cycle after C+11 to C+40 are initial-

ized. Therefore, when using the Always ON Flag (ON) as an execution condition for PIDAT(191), pro-

vide a separate process where C+11 to C+40 are initialized when operation is started.

Precautions

• A PID parameter storage word cannot be shared by multiple PIDAT instructions. Even when the same

parameter is used in multiple PIDAT instructions, separate words must be specified.

• When changing the PID constants manually, set the PID constant change enable setting (bit 1 of

C+5) to 1 so that the values in C+1, C+2, and C+3 are refreshed each sampling period in the PID cal-

culation. This setting also allows the PID constants to be adjusted manually after autotuning.

• Of the PID parameters (C to C+40), only the following parameters can be changed when the execu-

tion condition is ON. When any other values have been changed, be sure to change the execution

condition from OFF to ON to enable the new settings.

• Set value (SV) in C

(Can be changed during PID control only. An SV change during autotuning will not be

reflected.)

• PID constant change enable setting (bit 1 of C+5)

• P, I, and D constants in C+1, C+2, and C+3

(Changes to these constants will be reflected each sampling period only if the PID constant

change enable setting (bit 1 of C+5) is set to 1.)

• AT Command Bit (bit 15 of C+9)

• AT Calculation Gain (bits 0 to 14 of C+9) and Limit-cycle Hysteresis (C+10) (These values are

read when autotuning starts.)

Performance Specifications

Calculation Method

Calculations in PID control are performed by the target value filtered control with two degrees of

freedom.

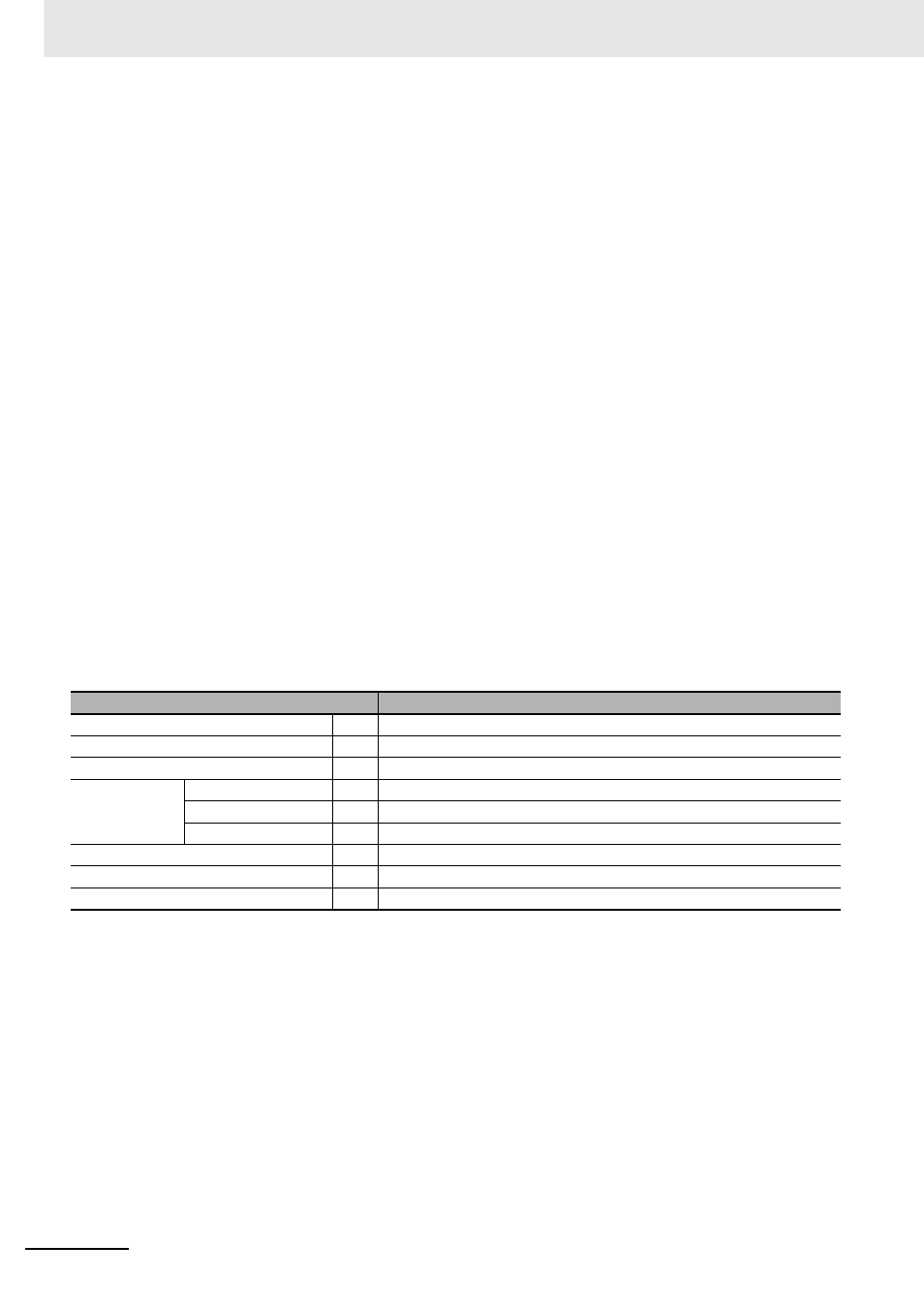

Item

Specifications

PID control method

---

Target value filter-type two-degrees-of-freedom PID method (forward/reverse)

Number of PID control loops

---

Unlimited (1 loop per instruction)

Sampling period

τ

0.01 to 99.99 s

PID constant

Proportional band

P

0.1 to 999.9%

Integral constant

Tik

1 to 8191, 9999 (No integral action for sampling period multiple, 9999.)

Derivative constant

Tdk

0 to 8191 (No derivative action for sampling period multiple, 0.)

Set value

SV

0 to 65535 (Valid up to maximum value of input range.)

Measured value

PV

0 to 65535 (Valid up to maximum value of input range.)

Manipulated variable

MV

0 to 65535 (Valid up to maximum value of output range.)