Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 77

Publication 1394-5.0 — May 2000

Wiring System, Axis, and Shunt Modules, and Motors (for all systems)

3-31

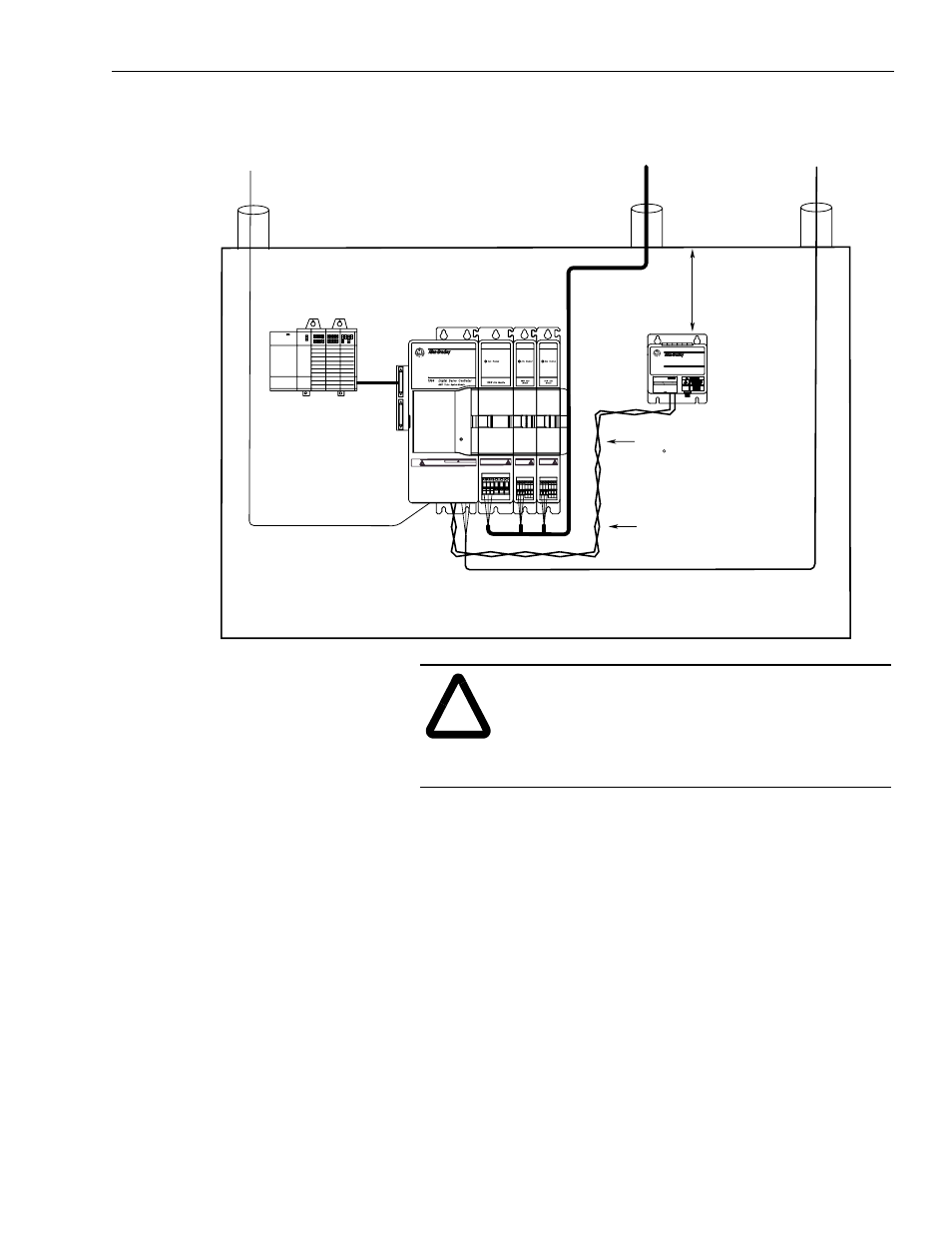

Figure 3.19

Routing Shunt Module Wiring When Module is Inside the Cabinet

7. Open the front door of the shunt module.

8. Insert the wire from the system module terminal block labeled

COL in the top terminal on the left side of the shunt module.

Refer to Figure 3.20 for the terminal’s location.

9. Insert the wire from the system module terminal block labeled

DC+ in the bottom terminal on the left side of the shunt module.

Refer to Figure 3.20 for the terminal’s location.

!

ATTENTION: To avoid burn hazard and ignition of

flammable material, be sure to provide appropriate

guarding. The resistors inside the 1394 shunt module

can reach temperatures in excess of 350

°

C (662

°

F).

Install per local codes.

Status

Low voltage

Communications

Control I/O wiring

Motor feedback cables

360/480V

AC power

Always separate all low voltage signal

wiring from high voltage power wiring to

reduce affects of EMI and RFI.

Motor power

cables

155 mm (6.1 in.) of

clearance on all sides

of the shunt module

minimum

Use twisted conductors

(2 twists per foot) min. or

a shielded twisted pair.

8 AWG (8.4 mm

2

),

105 C, 600V wire

Max. Length 3.05 m

(10 ft) for each wire

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Shielding is recommended

for reducing the effects

of EMI and RFI.

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.