Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 180

Publication 1394-5.0 — May 2000

9-14

Troubleshooting

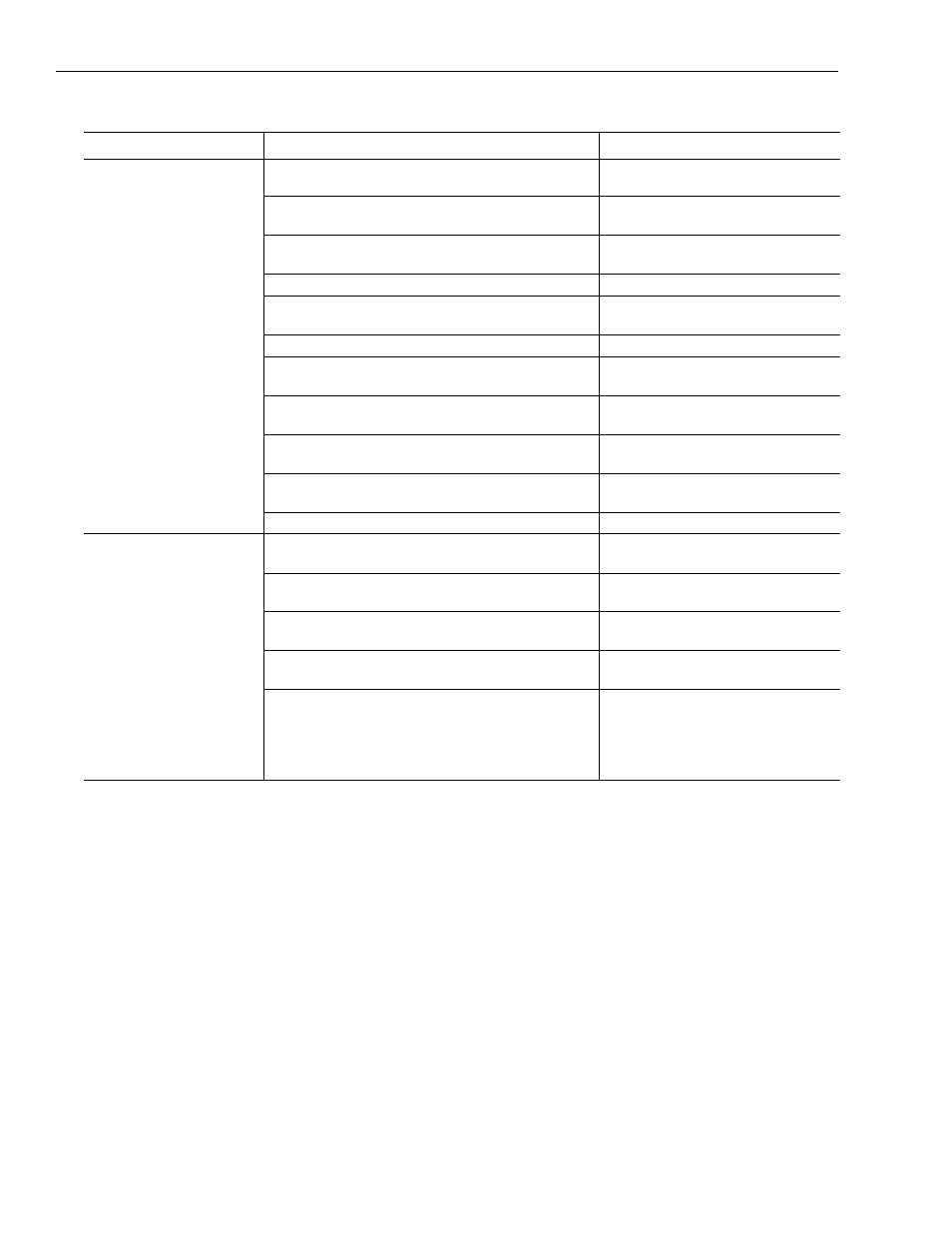

Condition:

Potential cause:

Possible resolution:

Motor does not respond to

a Velocity Command

Check for possible faults.

Verify that the parameters are set

correctly and correct them, as necessary.

The axis cannot be enabled for 1.5 seconds after

disabling.

Disable the axis, wait for 1.5 seconds,

and enable the axis.

Enable signal has not been applied or the enable wiring is

incorrect.

• Check the controller.

• Check the wiring.

The motor wiring is open.

Check the wiring.

The motor thermal overload has tripped.

• Check for a fault.

• Check the wiring.

The motor has malfunctioned.

Repair or replace the motor.

The coupling between motor and machine has broken

(i.e., the motor moves, but the load/machine doesn’t).

Check and correct the mechanics.

[Vel Source] parameter (364 (Analog Servo only)) is set

incorrectly.

Check and properly set the parameter.

[Torq Source] parameter (360 (Analog Servo only)) is set

incorrectly.

Check and properly set the parameter.

[CW, CCW VEL Lim] parameters (128, 132 (Analog

Servo only)) are set incorrectly.

Check and properly set the parameter.

The axis module has a malfunction.

Replace the axis module.

Presence of noise on

Command or resolver

signal wires

Recommended grounding per installation instructions

and Appendix B has not been followed.

• Verify grounding.

• Route wire away from noise sources.

External 50/60 Hz line frequency may be present.

• Verify grounding.

• Route wire away from noise sources.

External 100/120 Hz from a single phase logic supply

may be present.

• Verify grounding.

• Route wire away from noise sources.

External180 or 360 Hz from other adjustable speed

drives may be present.

• Verify grounding.

• Route wire away from noise sources.

Variable frequency may be velocity feedback ripple or a

disturbance caused by gear teeth or ballscrew balls etc.

The frequency may be a multiple of the motor power

transmission components or ballscrew speeds resulting in

velocity disturbance.

• Decouple the motor for verification.

• Check and improve mechanical

performance of the gearbox, ballscrew,

etc.