Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 226

Publication 1394-5.0 — May 2000

A-28

Specifications

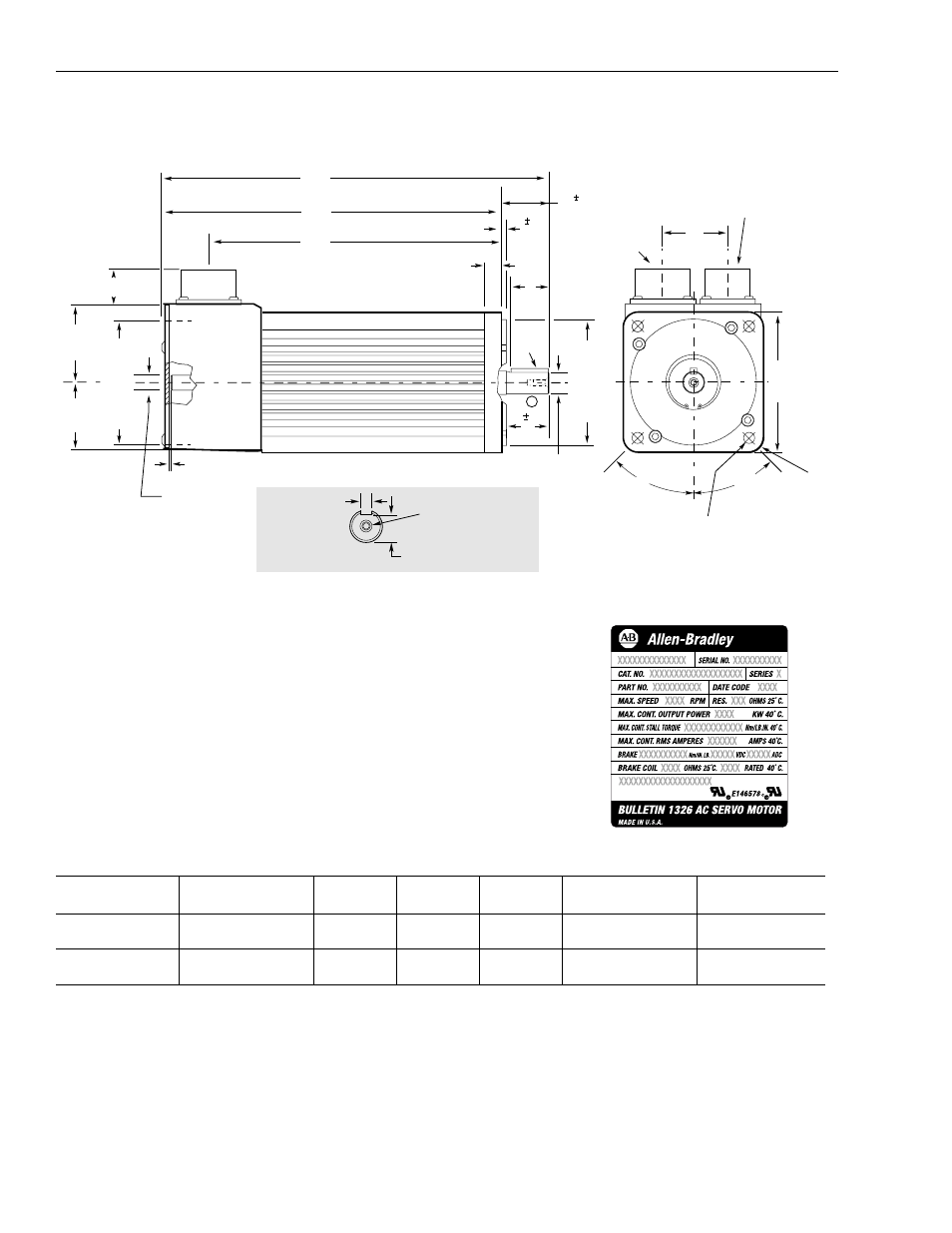

Figure A.20

1326AS-B3 Series Servo Motor

!

Shaft and Pilot Tolerances

Shaft Runout

0.025 (0.001) T.I.R

Shaft Endplay

0.025 (0.001)

Pilot Eccentricity

0.08 (0.0032) T.I.R

Maximum Face Runout

0.08 (0.0032) T.I.R

Shaft Detail

45 45

C

AG

AD

10.9

Key

20

5.00/4.97

9.525/9.500 Dia.

(0.375/0.374)

(0.429)

(0.787)

(0.118)

(1.181)

(1.063)

89 sq.

(3.50)

(0.197/0.196)

M4 x 0.7 Tapped hole

10 (0.39) Deep min.

Power Input

Commutation

Resolver Output

14.008/13.997

(0.5515/0.5511)

76.18/76.23 Dia.

(2.999/3.001)

80.012/79.993

(3.150/3.149)

11.00/10.90

(0.433/0.429)

50

(1.97)

43

(1.69)

23

(0.91)

7 mm Dia. Thru-Hole

4 required on a 100 mm Dia. B.C.

1.53

(0.060)

41

(1.61)

1

30 0.5

3 0.2

27 0.3

Motor Front End

Cap Corner Radius

9.1

(.36)

+_ .254 (.010)

Name Plate Detail

Flange Mount in millimeters and (inches)

Catalog number

Description

1

AD

AG

C

Key

End milled

keyway (full depth)

1326AS-B310

x-21

without brake

135

(5.32)

165

(6.50)

195

(7.68)

5 x 5 x 20

(0.197 x 0.197 x 0.79)

20

(0.79)

1326AS-B330

x-21

without brake

186

(7.32)

216

(8.50)

246

(9.68)

5 x 5 x 20

(0.197 x 0.197 x 0.79)

20

(0.79)

1

If you are ordering a 1326AS-B3

xxxx-21-K3 with an optional 24V DC 2.26 N-m (20 lb-in.) brake, add 39 mm (1.54 in.) to AD, AG and C.

Dimensions are per NEMA Standards MG 7-2.4.1.3 and IEC 72-1. Shaft and pilot tolerances are per DIN 42955, N tolerance.