Shunt module mounting orientation – Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 42

Publication 1394-5.0 — May 2000

2-12

Installing Your 1394 (applies to all systems)

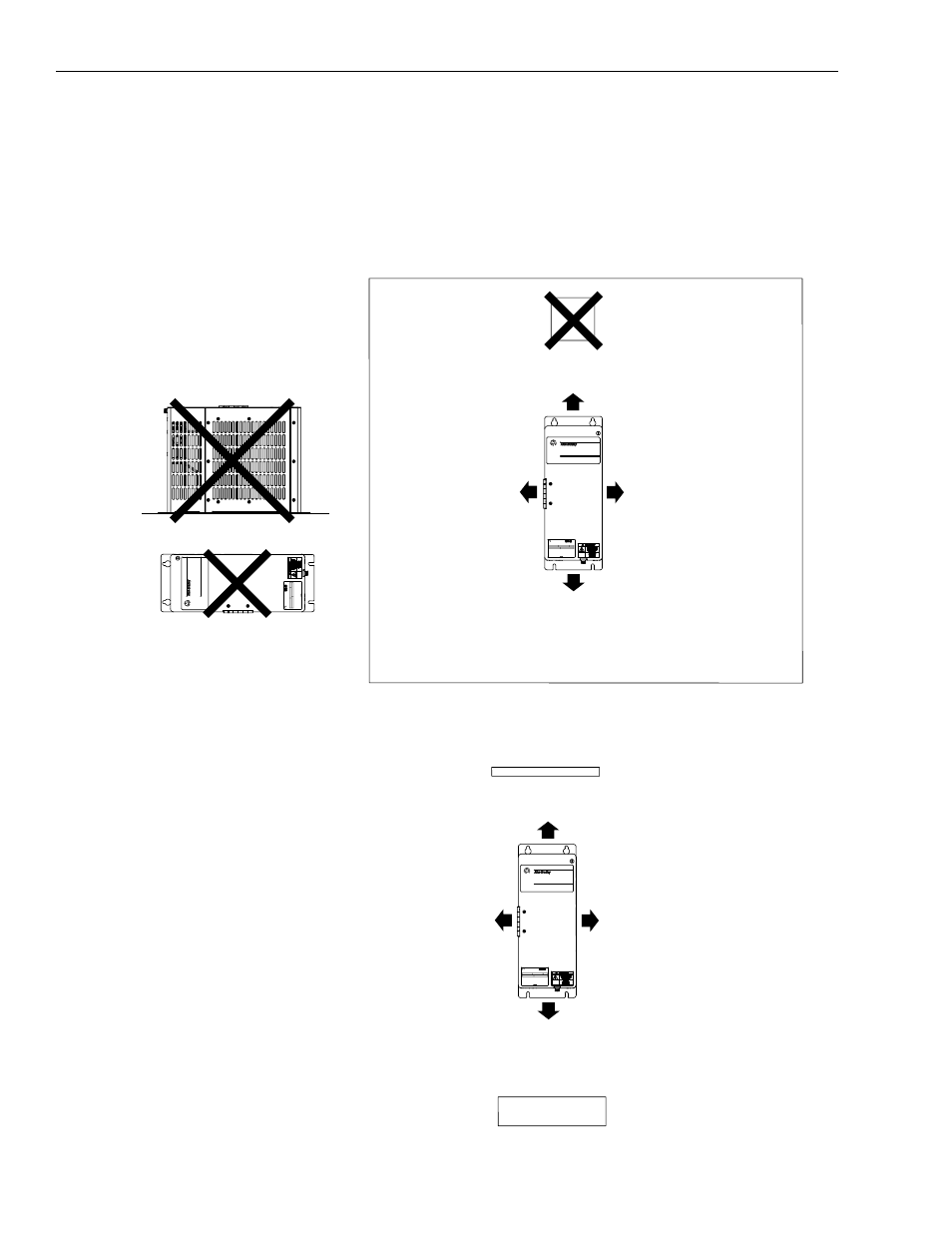

Shunt Module Mounting Orientation

Because the shunt module dissipates excess regenerative power in the

form of heat, you need to consider the following guidelines. Refer to

Figure 2.11 and Figure 2.12 for shunt module spacing requirements.

Figure 2.11

Shunt Module Spacing Requirements Within an Enclosure

Figure 2.12

Shunt Module Spacing Requirements Outside of an Enclosure

254 mm (10.0 in.) clearance

for airflow and installation

155 mm (6.1 in.) clearance

for airflow and installation

155 mm (6.1 in.) clearance

for airflow and installation

155 mm (6.1 in.) clearance

for airflow and installation

Wire entry area

for signal, power and motor connections

Top of cabinet

Temperature sensitive component

(mounted above shunt module)

Incorrect Shunt Placement

1394 Digital Servo Controller

3600W Shunt Module

BULLETIN 1394 3600W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

1394 Digital Servo Controller

3600W Shunt Module

BULLETIN 1394 3600W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Enclosure

254 mm (10.0 in.) clearance

for airflow and installation

155 mm (6.1 in.) clearance

for airflow and installation

155 mm (6.1 in.) clearance

for airflow and installation

155 mm (6.1 in.) clearance

for airflow and installation

Wire entry area

for signal, power and motor connections

Solid protective plate

1394 Digital Servo Controller

3600W Shunt Module

BULLETIN 1394 3600W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R