Checking for a blown fuse in the 1394-dclm – Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 189

Publication 1394-5.0 — May 2000

Troubleshooting

9-23

Checking for a Blown Fuse in the

1394-DCLM

To check the 1394-DCLM for a blown fuse:

1. Remove power from your system including the 1394-DCLM.

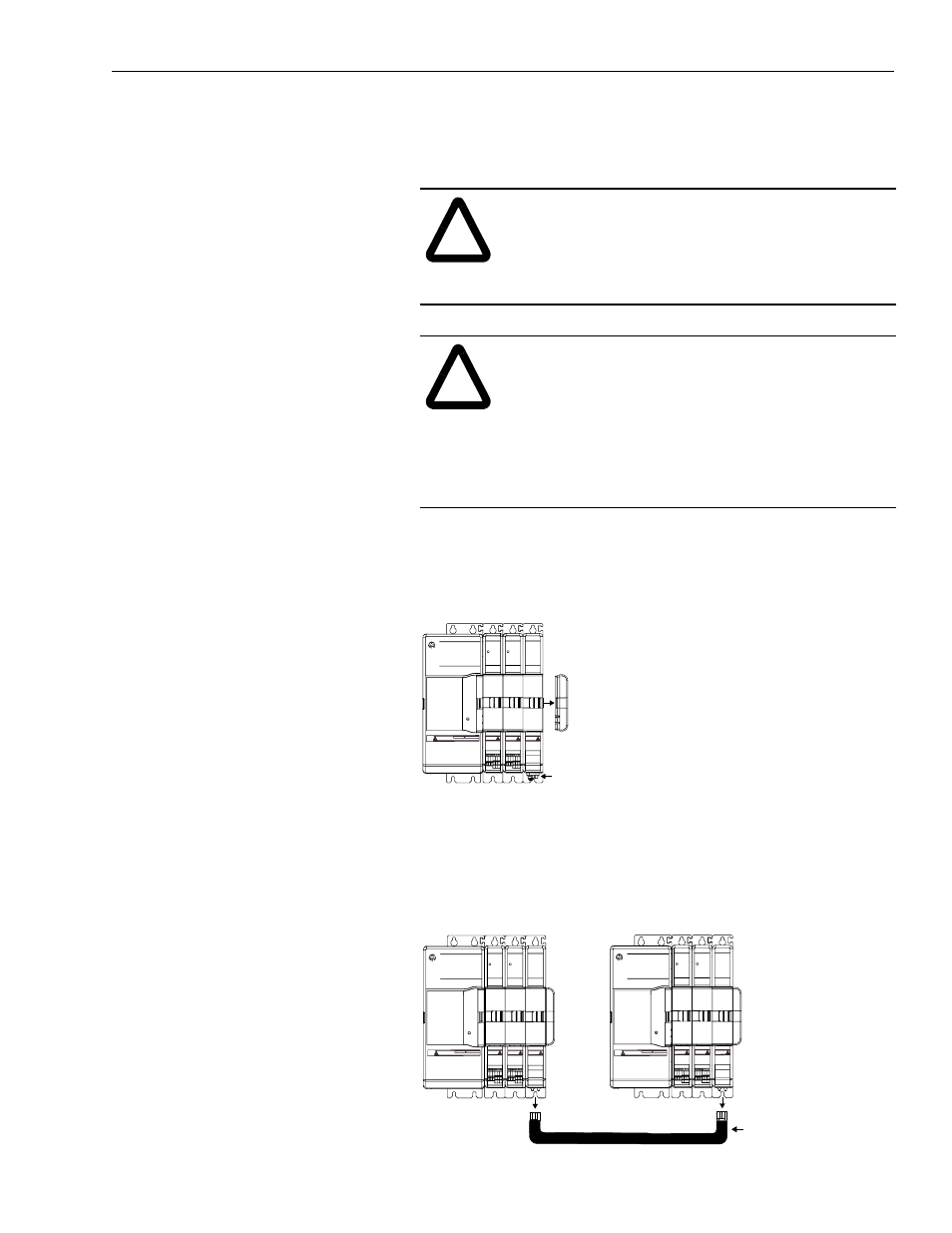

2. Remove the terminator from the right side of the 1394-DCLM.

Figure 9.3

Removing the Terminator from the 1394-DCLM

3. Remove either the power plug from the stand-alone 1394-DCLM

(shown above) or remove the cable linking two systems together,

as shown below.

Figure 9.4

Removing the Cable from the 1394-DCLM

!

ATTENTION: To avoid shock hazard or personal

injury, assure that all power has been removed before

proceeding. This system may have multiple sources of

power. More than one disconnect switch may be

required to de-energize the system.

!

ATTENTION: To avoid hazard of electrical shock,

verify that all voltage on the capacitors has been

discharged before attempting to service, repair, or

remove this unit. This product contains stored energy

devices. You should only attempt the procedures in this

document if you are qualified to do so and familiar with

solid-state control equipment and the safety procedures

in publication NFPA 70E.

Terminator

DC Link

Module

1394 Digital Servo Controller

System Module

Allen-Bradley

Cable plug

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

DC Link

Module

1394 Digital Servo Controller

System Module

Allen-Bradley

DC Link

Module

1394 Digital Servo Controller

System Module

Allen-Bradley

DCLM cable

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.