Understanding analog servo system axis faults – Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 178

Publication 1394-5.0 — May 2000

9-12

Troubleshooting

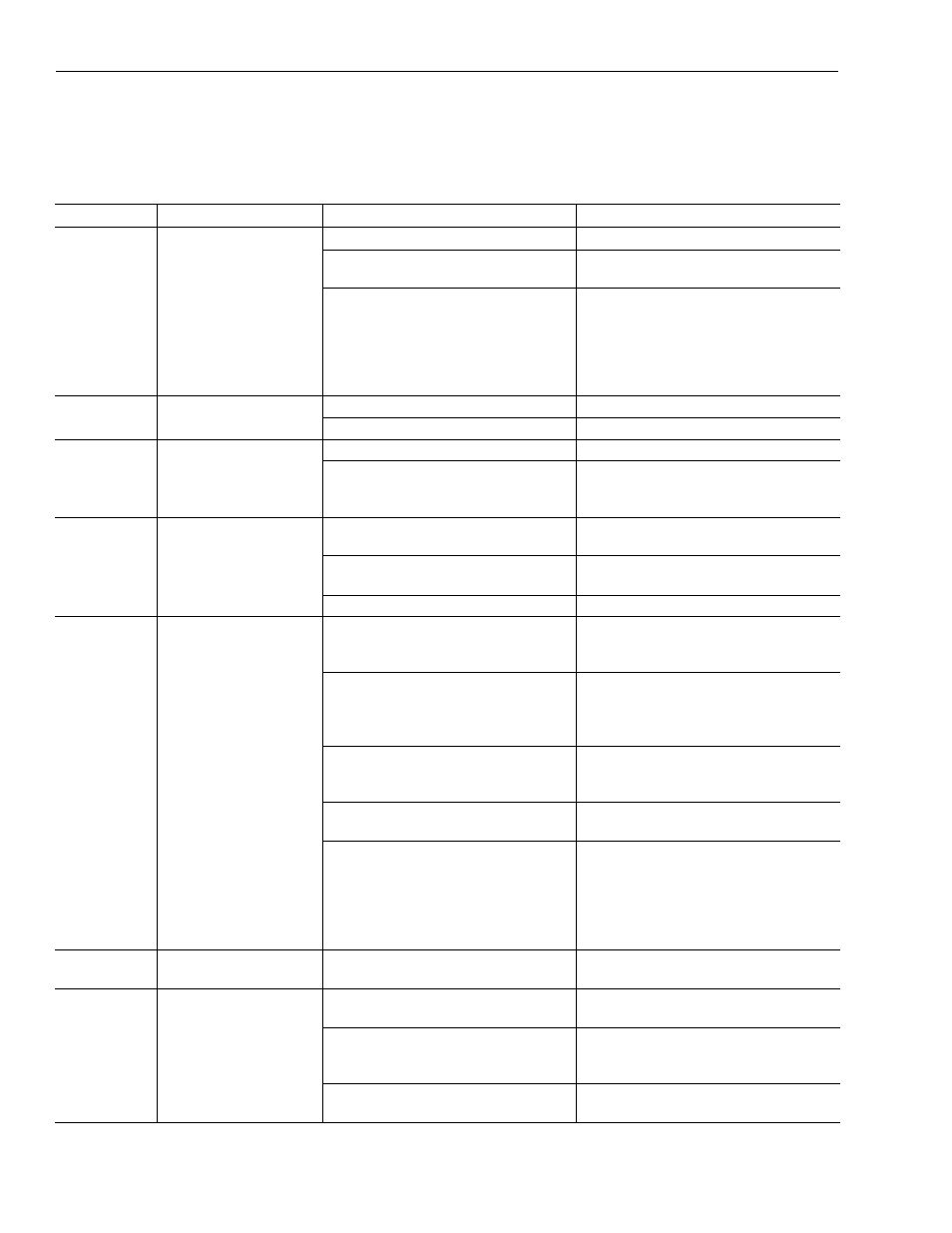

Understanding Analog Servo System Axis Faults

The faults that apply to the Analog Servo System’s axis module

appear in the following table.

Fault Message:

Description:

Potential Cause:

Possible resolution:

ATune Fault

The auto tune cycle has

exceeded two seconds.

Motor is disconnected or not able to turn.

Connect the motor.

Motor power/resolver wiring is open or

improperly wired.

Check motor power/resolver wiring.

Axis enable has not been applied within

60 seconds of fault during auto tune.

• Increase the auto tune current limit to

increase motor torque.

• Decrease the auto tune velocity to decrease

the auto tune cycle time. You must apply

the enable signal within 60 seconds during

auto tune.

Bus Loss

The DC bus supply to the

axis module was lost.

The slider connections may not be secure.

Check slider connections/termination strip.

An axis module’s bus link fuse has blown.

Replace the module.

Ring Write!

The axis module is not set

to proper scaling.

The slider connections may not be secure.

Check slider connections/termination strip.

The axis module is malfunctioning.

• Terminate signal common (TB1-19) to

chassis (PE) ground.

• Replace the module.

Fdbck Loss

(Resolver)

The resolver wiring is

open, shorted, or missing.

Open or short circuit has occurred on

resolver wiring.

Check the resolver cable connectors/wiring to

the system module and motor.

The resolver wiring or termination to

system module is incorrect.

Check the resolver cable connectors/wiring to

the system module and motor.

The motor resolver might be bad.

Replace the motor resolver.

I(t) Fault

The output current is

exceeding the time-current

rating.

Accel/decel command from position

controller is requiring peak current for an

excessive amount of time.

Change the command profile to reduce speed

or increase time.

The machine friction, inertial load, and/or

viscous load is excessive.

• Change the command profile to reduce

speed or increase time.

• Check for mechanical problems on the

machine.

The motor has been improperly sized.

• Check motor size for your application.

• Contact your Allen-Bradley Support

Representative.

A short circuit exists across the drive

output terminals.

Check wiring between the axis and the motor.

Logic supply circuits have malfunctioned

or AC output is incorrectly wired.

• Check wiring between the axis and the

motor.

• Check power wiring between the axis and

the motor.

• Check resolver wiring between the system

module and the motor.

Ovr Speed

Motor velocity exceeded

the overspeed trip limit.

Motor velocity has exceeded the

overspeed value.

• Verify operating parameters.

• Verify application requirements.

Ovr temp

The 1394 contains a

thermal sensor that senses

the internal ambient

temperature.

The cabinet’s ambient temperature is

above rating.

Check the cabinet temperature

The machine’s duty cycle requires an

RMS current exceeding the continuous

rating of the controller.

Change the command profile to reduce speed

or increase time.

The airflow access to the 1394 is limited

or blocked.

Check airflow and re-route cables away from

the 1394.