Rockwell Automation 1326 Digital AC Multi-Axis Motion Control System User Manual User Manual

Page 229

Publication 1394-5.0 — May 2000

Specifications

A-31

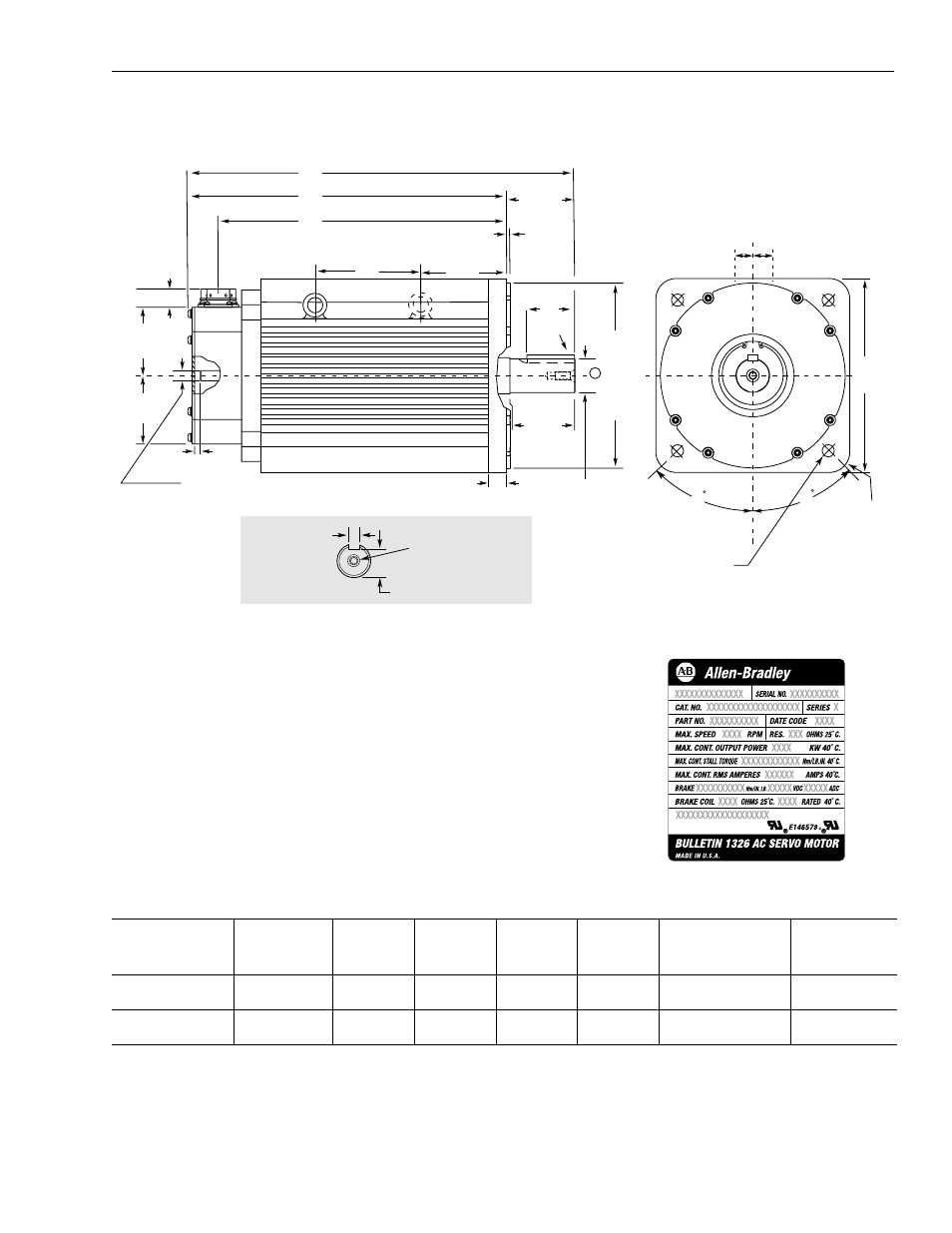

Figure A.23

1326AS-B8 Series Servo Motor

!

Shaft and Pilot Tolerances

Shaft Runout

0.05 (0.002) T.I.R

Shaft Endplay

0.025 (0.001)

Pilot Eccentricity

0.10 (0.004) T.I.R

Maximum Face Runout

0.10 (0.004) T.I.R

Flange Mount in millimeters and (inches)

Catalog number

Description

1

AL

AD

AG

C

Key

End milled

keyway

(full depth)

1326AS-B840

x-21

without brake

131

(5.15)

308

(12.13)

346

(13.63)

431

(16.97)

12 x 8 x 60

(0.472 x 0.315 x 2.36)

60

(2.36)

1326AS-B860

x-21

without brake

235

(9.25)

359

(14.13)

397

(15.63)

482

(18.97)

12 x 8 x 60

(0.472 x 0.315 x 2.36)

60

(2.36)

1

If you are ordering a 1326AS-B8

xxxx-21-K8 with an optional 24V DC 50.9 N-m (450lb-in.) brake, add 103 mm (4.05 in.) to AD, AG and C. Add 51 mm (2.0 in) to AL.

Dimensions are per NEMA Standards MG 7-2.4.1.3 and IEC 72-1. Shaft and pilot tolerances are per DIN 42955, N tolerance. The eye bolt diameter is 38.1 mm (1.50 in)

O.D. x 22.35 mm (0.88 in) I.D.

Shaft Detail

241 sq.

(9.49)

45

45

C

AG

AD

60

(2.36)

230.000/229.954

9.055/9.053

81.0 ± 0.3

(3.19)

4.0 ±0.2

(0.157)

22.4

(0.882)

7.7/6.2

0.305/0.245

85.0±0.5

(3.35)

42.000/41.984

(1.654/1.653)

0.4997/0.4990

12.692/12.675

23

(0.91)

12.00/11.96

(0.472/0.471)

M8 x 1.25 Tapped hole

20 (0.79) Deep min.

37.00/36.80

(1.457/1.449)

15 mm Dia. Thru-hole

4 required on a 265 mm Dia. B.C.

85

(3.35)

85

(3.35)

25

(0.98)

33

(1.3)

1

Key

73.15

(2.88)

AL

Motor Front End

Cap Corner Radius

25.4

(1.00)

+_ .397 (.015)

Name Plate Detail