NORD Drivesystems BU0180 User Manual

Page 90

SK 180E Manual for frequency inverters

90

Pre-series version

BU 0180 GB-0914

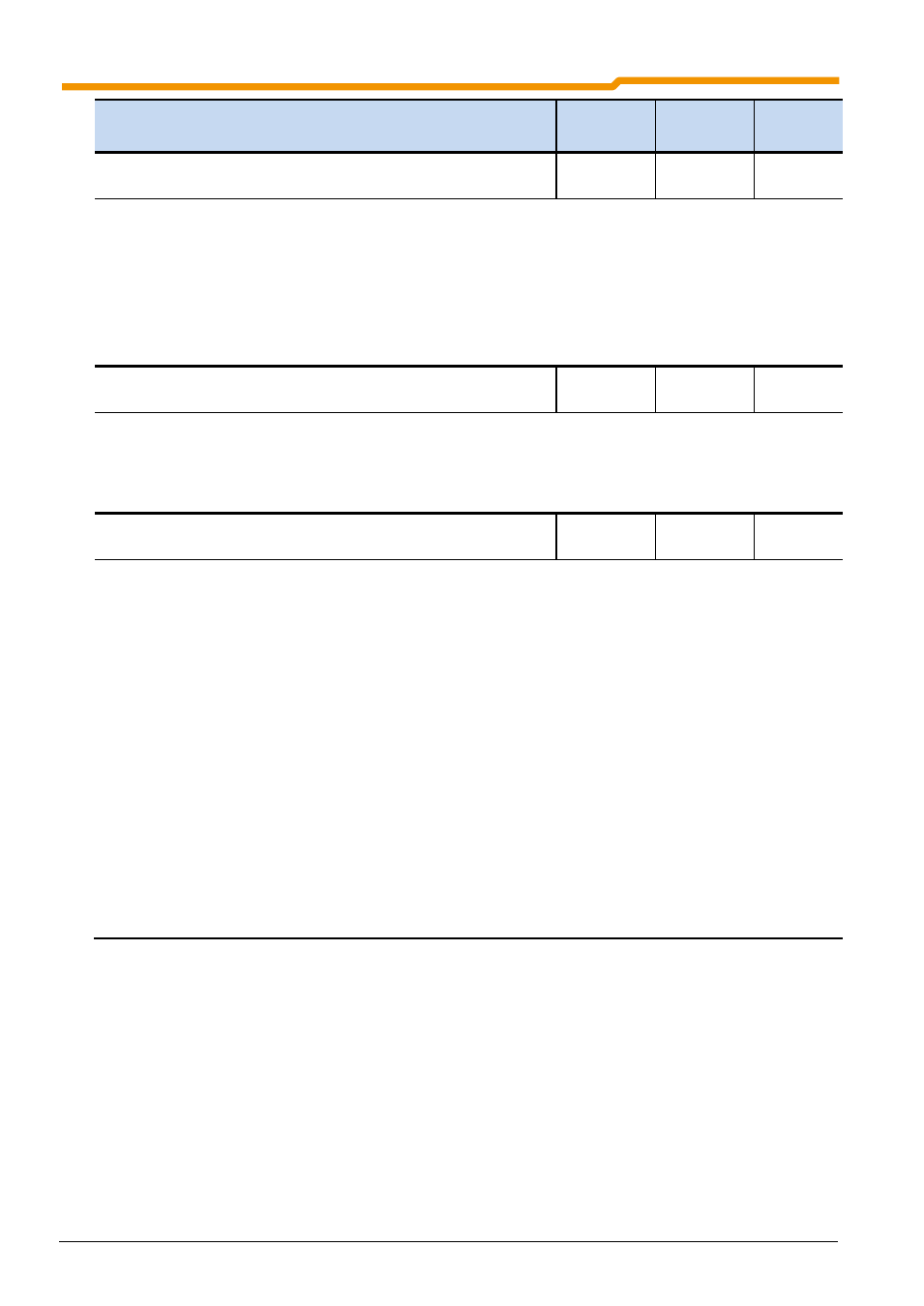

Parameter

{Factory setting}

Setting value / Description / Note

Device

Supervisor

Parameter

set

P217

Oscillation damping

(Oscillation damping)

S

P

0 ... 400 %

{ 10 }

With the oscillation damping, idling current harmonics can be damped. Parameter 217 is a

measure of the damping power.

For oscillation damping the oscillation component is filtered out of the torque current by means

of a high pass filter. This is amplified by P217, inverted and switched to the output frequency.

The limit for the value switched is also proportional to P217. The time constant for the high pass

filter depends on P213. For higher values of P213 the time constant is lower.

With a set value of 10% for P217, a maximum of ± 0.045 Hz are switched in. At 400% in P217,

this corresponds to ± 1.8 Hz

P218

Modulation depth

(Modulation depth)

S

50 ... 110 %

{ 100 }

This setting influences the maximum possible output voltage of the FI in relation to the mains

voltage. Values <100% reduce the voltage to values below that of the mains voltage if this is

required for motors. Values >100% increase the output voltage to the motor increased the

harmonics in the current, which may cause swinging in some motors.

Normally, 100% should be set.

P219

Auto. Magn.adjustm.

(Automatic magnetisation adjustment)

S

25 ... 100 % / 101

{ 100 }

With this parameter, an automatic adjustment of the magnetizing to the motor load can be

made. P219 is a limiting value, to which the field in the motor can be reduced.

As standard, the value is set to 100%, and therefore no reduction is possible. As minimum, 25%

can be set.

The reduction of the field is performed with a time constant of approx. 7.5 sec. On increase of

load the field is built up again with a time constant of approx. 300 ms. The reduction of the field

is carried out so that the magnetisation current and the torque current are approximately equal,

so that the motor is operated with “optimum efficiency”. An increase of the field above the

setpoint value is not intended.

This function is intended for applications in which the required torque only changes slowly (e.g.

pumps and fans). Its effect therefore replaces a quadratic curve, as it adapts the voltage to the

load.

NOTE:

This must not be used for lifting or applications where a more rapid build-up of the

torque is required, as otherwise there would be overcurrent switch-offs or inversion

of the motor on sudden changes of load, because the missing field would have be

compensated by a disproportionate torque current.

101 = automatic, with the setting P219=101 an automatic magnetisation current controller is

activated. The ISD controller then operates with a subordinate magnetizing controller,

which improves the slippage calculation, especially at higher loads. The control times

are considerably faster compared to the Normal ISD control (P219 = 100)