1 connection, 2 configuration – NORD Drivesystems BU0180 User Manual

Page 66

SK 180E Manual for frequency inverters

66

Pre-series version

BU 0180 GB-0914

NOTE

For commissioning standard applications, a limited number of the frequency inverter inputs and

outputs (physical and I/O bits) have predefined functions. These settings may need to be

changed (Parameters (P420), (P434), (P480), (P481)).

5.2.1

Connection

After mounting the frequency inverter on the motor or the wall mounting kit, the mains and motor cables

must be connected to the relevant terminals

(PE, L1, N (/L2, L3) and U, V, W)

In principle, the frequency inverter can be operated in this configuration. (See Section 5.2.3)

5.2.2

Configuration

Changes to individual parameters are usually necessary for operation.

5.2.2.1

Parameterisation

The use of a ParameterBox (SK CSX-3H / SK PAR) or NORD CON software is necessary to change the

parameters.

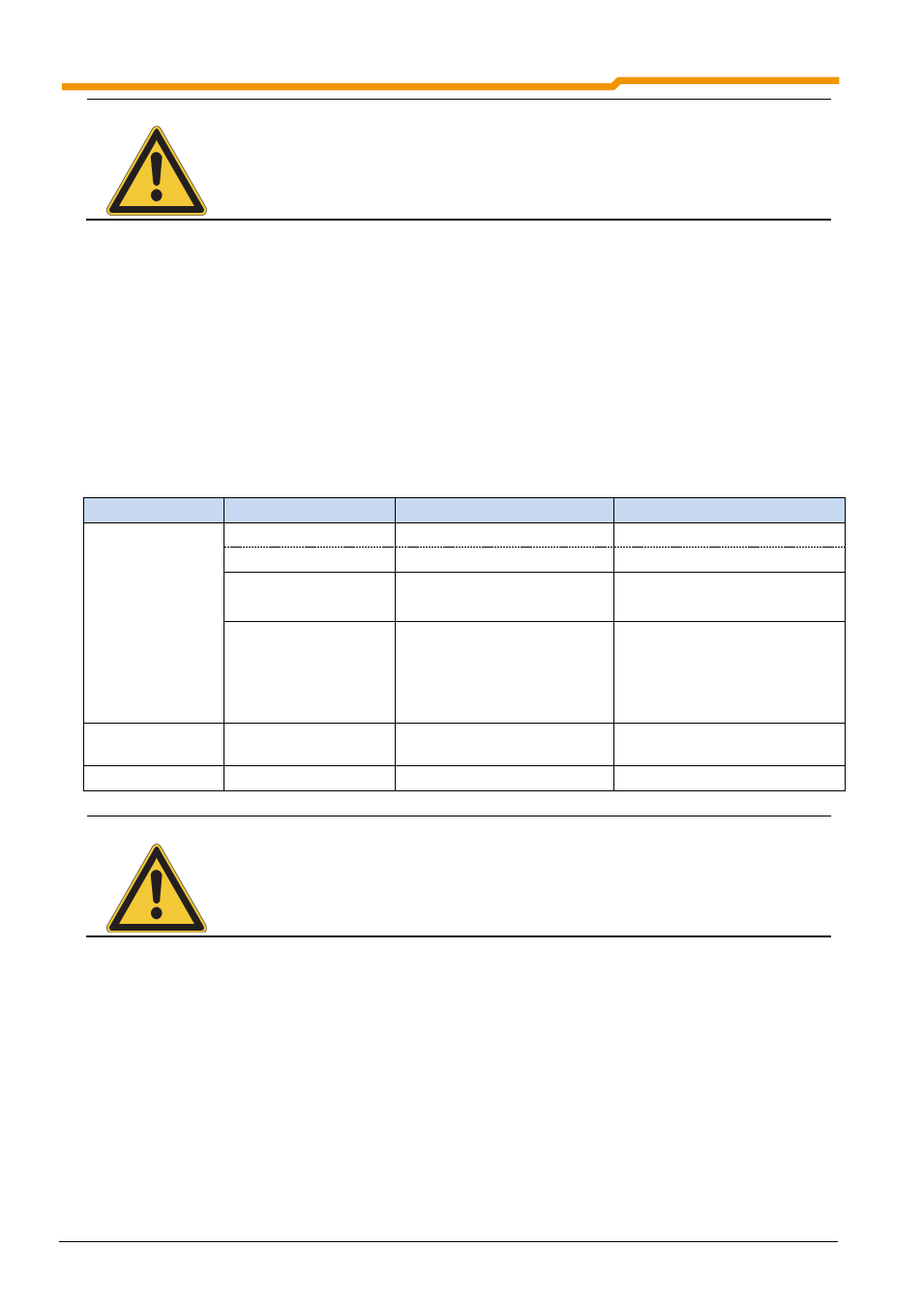

Parameter group

Parameter numbers

Functions

Comments

Motor data

P201 … P207, (P208) Data on motor rating plate

P220, Function 1

Measure stator resistance

Value is written to P208

alternatively

P200

Motor data list

Selection of a 4-pole standard

motor from a list

alternatively

P220, Function 2

Motor identification

Complete measurement of a

connected motor

Prerequisite: motor no more

than 3 power levels less than

the frequency inverter

Basic parameters

P102 … P105

Ramp times and frequency

limits

Control terminals

P400, P420

Analog and digital inputs

NOTE

Prior to commissioning, it should be ensured that the frequency inverter is in its default setting

(P523). DIP switches S2 should remain in the "off" setting. DIP switches S2 have priority over

the parameters P509, P514 and P515.